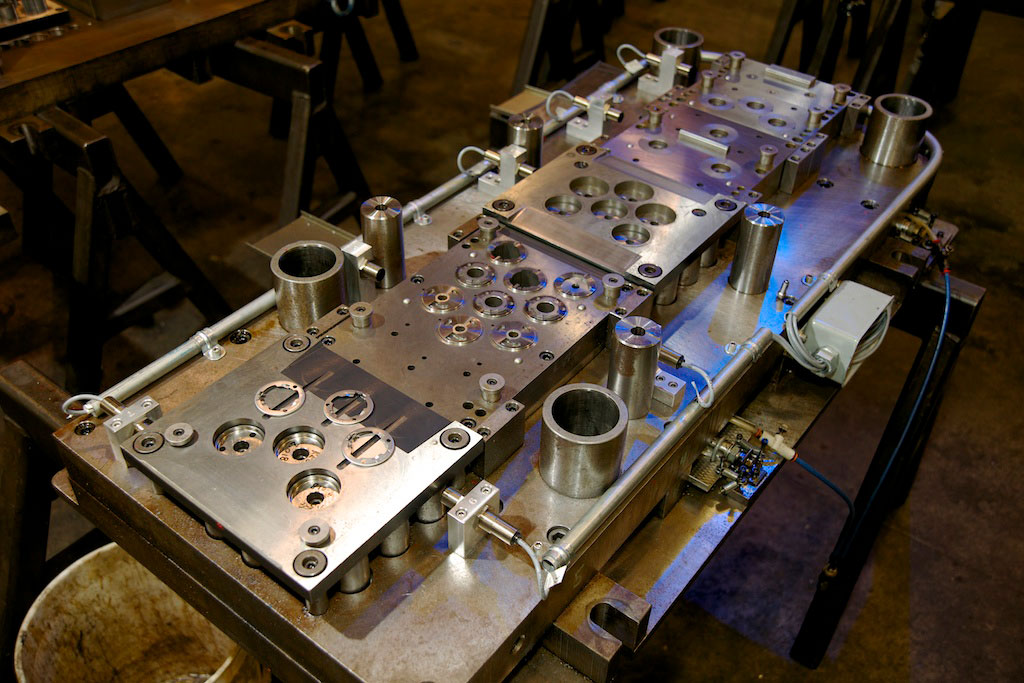

Precision manufacturing demands consistency, speed, and accuracy. This is where Custom Metal Stamping Dies play a crucial role. They serve as the foundation for producing high-volume components with exact tolerances. These dies are not generic; they are specifically tailored to meet unique product specifications. With custom dies, manufacturers can produce parts with minimal deviation and superior repeatability.

Tailored Designs for Specific Applications

Every industry has unique requirements; the automotive, aerospace, electronics, and medical sectors each demand specialised components. Custom Metal Stamping Dies are designed with these industry-specific needs in mind. From tight geometries to complex part profiles, custom dies handle it all with finesse.

This tailored approach ensures that each die aligns with production goals. It minimises the need for adjustments or tool changes during production. Moreover, custom dies enable easier integration with automated assembly lines, allowing manufacturers to streamline operations and improve throughput efficiently. Such flexibility enables greater customisation and scalability as market requirements evolve.

Enhancing Production Speed and Efficiency

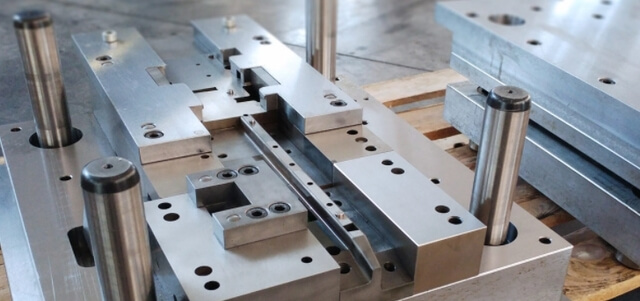

One significant benefit of Custom Metal Stamping Dies is their impact on production speed. Because these dies are engineered for a specific task, they perform with exceptional speed and accuracy. Less time is spent adjusting machines or correcting errors. This efficiency directly translates into higher output and faster delivery times.

Additionally, custom dies enhance press uptime and minimise tool wear. This keeps production moving without costly delays. As a result, manufacturers can fulfil orders faster and respond more quickly to changing market demands. This level of operational agility is essential in today’s fast-paced manufacturing environment, where timing is often critical to customer satisfaction.

Reducing Waste and Material Costs

Custom Metal Stamping Dies also play a pivotal role in reducing material waste. Their precision design ensures optimal use of raw materials. By minimising scrap, these dies lower overall production costs and promote sustainable manufacturing practices that meet modern regulatory standards.

Furthermore, custom dies contribute to better resource planning. Since engineers can predict material usage more accurately, they can reduce overstock and understock risks. This leads to a leaner supply chain and a more environmentally responsible manufacturing process. Efficient resource use also supports long-term cost savings and energy conservation.

Improving Product Consistency and Tolerance Control

Achieving consistent product quality is critical in precision manufacturing. Custom metal stamping dies make this possible by delivering exact tolerances with every cycle. Their design accounts for part geometry, material characteristics, and forming pressures across varying production environments.

The result is less variation between parts and fewer quality control issues. This consistency builds brand trust and reduces the time and cost associated with inspections and rework. For industries like aerospace and automotive, where safety and reliability are paramount, this level of control is non-negotiable. It also supports regulatory compliance and customer satisfaction simultaneously.

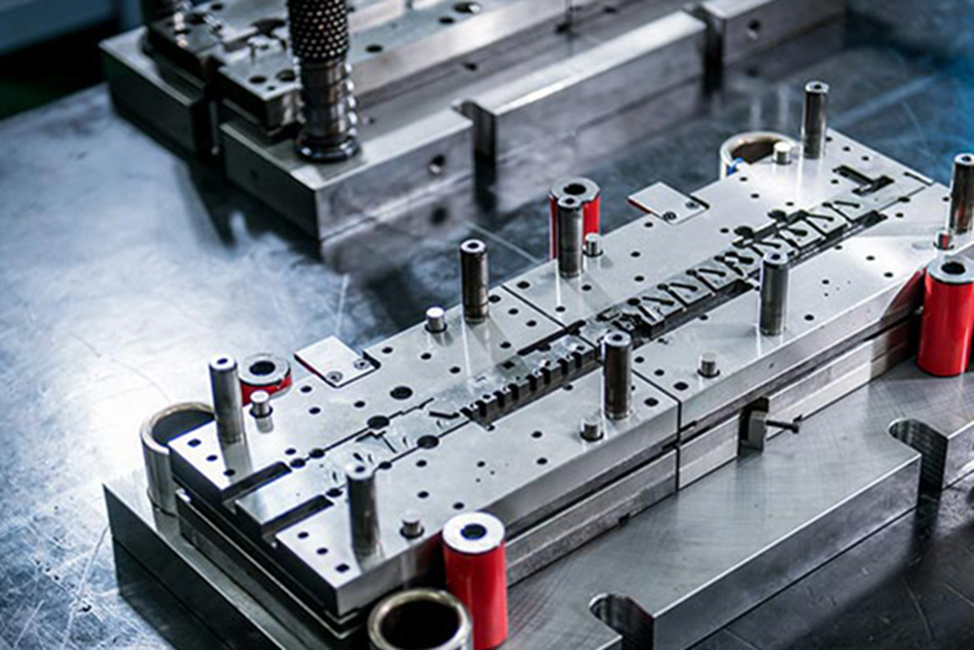

Supporting Complex Geometries and Innovative Designs

Modern products often feature intricate designs. Custom Metal Stamping Dies are capable of producing these shapes reliably and efficiently. Whether it’s micro-components or large panels, these dies are designed to meet the demands of complex engineering and technical standards.

This capability opens the door to innovation. Designers can push boundaries without worrying about manufacturing limitations. As a result, companies can bring new products to market faster and maintain a competitive edge through design differentiation and rapid prototyping. The proper tooling can be the key to successful product development cycles.

Boosting Tool Longevity and Maintenance Predictability

Tool longevity is another hidden benefit of Custom Metal Stamping Dies. These tools are built to withstand repetitive cycles and harsh conditions. Because they are optimised for specific applications, wear and tear are minimised even during intensive production phases.

Longer tool life means fewer replacements and less downtime. Moreover, custom dies allow for predictive maintenance. Engineers can monitor wear patterns and plan service schedules accordingly. This proactive approach helps maintain productivity and prevent costly production stoppages. It also simplifies budget forecasting and extends overall equipment life.

Custom Metal Stamping Dies Drive Precision, Efficiency, and Innovation in Manufacturing

Custom Metal Stamping Dies are indispensable to precision manufacturing. They improve part quality, speed up production, reduce waste, and support design innovation. With the right Custom Metal Stamping Dies, companies position themselves to lead in high-performance markets where accuracy and speed matter most.