Progressive Stamping Dies

- Home

- Service

- Progressive Stamping Dies

Our Service

Service List

- Design & Engineering

- Precision Dies

- Die Assembly & Die Tryout

- Precision Parts

- Tooling&Jigs

Need For Some Help ?

For More Details Contact Us!

Phone

+86 0769-82759388-825 +86 0769-81502216-826

info@cymjkj.com

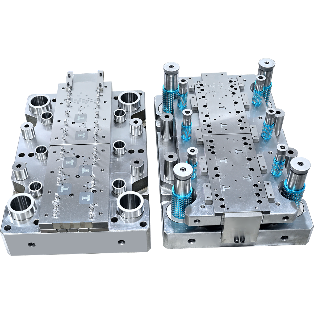

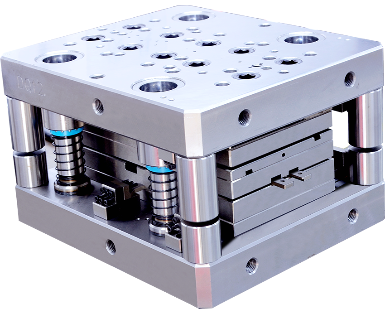

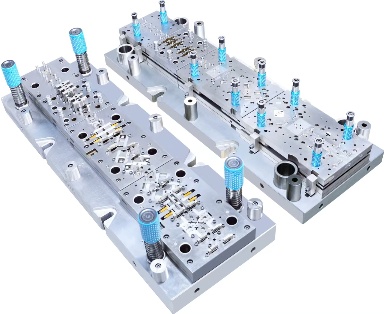

Precision Metal Stamping Die

Precision metal stamping dies, especially Progressive Stamping Dies, are the cornerstone of high-volume manufacturing, enabling the production of intricate, high-tolerance metal components critical to advanced industries. Utilizing cutting-edge design, advanced materials, and meticulous engineering, these metal stamping dies—including high-speed progressive stamping dies and multi-stage progressive stamping dies—transform raw metal sheets or coils into precise parts through processes such as blanking, punching, bending, and forming. Our expertise in Progressive Stamping Dies ensures components meet stringent requirements for dimensional accuracy, durability, and performance, supporting industries where reliability is non-negotiable.

Our Expertise

As a leading precision metal stamping dies manufacturer, we specialize in delivering tailored solutions for complex applications across diverse sectors. Our core competencies include:

Product Portfolio

Terminals & Connectors: High-speed, ultra-precision dies for electrical and data transmission systems.

LED & IC Components: Micro-stamping dies for delicate semiconductor and optoelectronic parts.

Motor & Electromechanical Parts: Durable dies for motors, relays, and miniature mechanical assemblies.

Customised Solutions: Bespoke dies engineered for unique geometries and material challenges.

Technical Capabilities

Advanced CAD/CAM and simulation tools for die design optimisation.

Precision machining with JG, PG, CNC, wire-cutting, and precision surface grinding technologies.

Rigorous quality control via CMM measurement and material testing.

Prototyping to mass production with fast turnaround and scalability.

Key Features of Our Progressive Stamping Dies

√ SolidWorks tool design

√ Material thickness 0.1-2.0mm

√ Simple blank through dies to complex progressive dies

√ Die components made of carbide, ceramic, powder metals, or conventional tool steel

√ Die Assembly & Die Tryout

Why Partner With Us?

1. Decades of Proven Expertise

With years of hands-on experience in precision metal stamping, we bring unmatched industry knowledge to every project.

2. Innovation Meets Reliability

We integrate cutting-edge technologies with proven manufacturing methods to deliver stamping dies that consistently exceed performance expectations.

3. Commitment to Research & Development

Our continuous investment in advanced R&D allows us to optimize designs and create innovative solutions for complex challenges.

4 .Strict Quality Assurance

We adhere to rigorous quality control standards, ensuring every die meets the highest benchmarks for accuracy, durability, and consistency.

5.Customer-Centric Collaboration

Your success is our priority—we work closely with clients to provide fully tailored solutions that seamlessly integrate into your production processes.

6.Trusted Across High-Stakes Industries

From advanced electronics to aerospace and defense, our dies are trusted in industries where precision and reliability are non-negotiable.

FAQ

Progressive stamping dies are specialized tools used to produce complex metal parts through a series of sequential operations in a single die set. These operations may include punching, bending, and forming, all performed as the material progresses through the die.

Progressive stamping dies are widely used in automotive, electronics, aerospace, telecommunications, and consumer goods industries. They are ideal for high-volume production where tight tolerances and consistent quality are required.

Common materials include stainless steel, aluminum, copper, brass, and high-strength alloys. Our tooling solutions are designed to accommodate a wide range of metal thicknesses and material grades based on your project’s specific requirements.

Progressive stamping dies significantly increase production speed and reduce labor costs by combining multiple forming steps into one continuous process. They also minimize material waste and deliver consistent part quality throughout large production runs.

Yes, we specialize in custom progressive stamping dies tailored to your exact specifications. Our engineering team works closely with clients to develop solutions for challenging part geometries, tight tolerances, and specific material needs.

Make An Appointment

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN