In the world of precision metal stamping, the choice between fine blanking and progressive die can have a significant impact on product quality and production efficiency. Although both are used to manufacture complex metal parts, their mechanisms, output quality, die complexity, and cost impact differ. In actual production, the choice between them often leaves engineers torn. Both technologies have proven their value in mass-production environments; however, choosing the wrong technology may result in higher costs, increased scrap rates, or unacceptable tolerances.

How the Two Processes Work

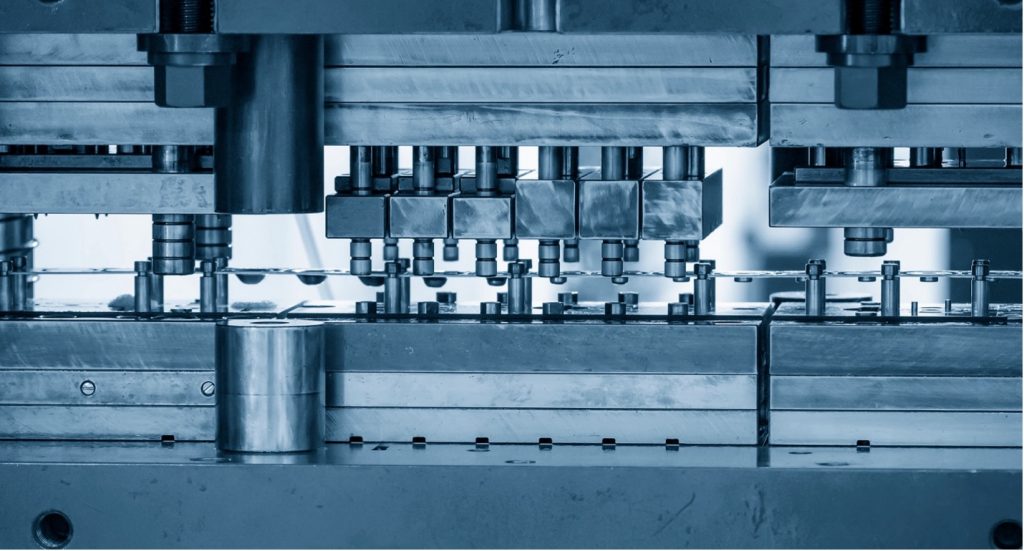

Fine blanking and progressive die stamping rely on different mechanical principles. Fine blanking uses triple-action presses that apply simultaneous forces to minimise part distortion. A V-ring holds the material in place while a counter punch eliminates burrs. The result is a clean, straight edge.

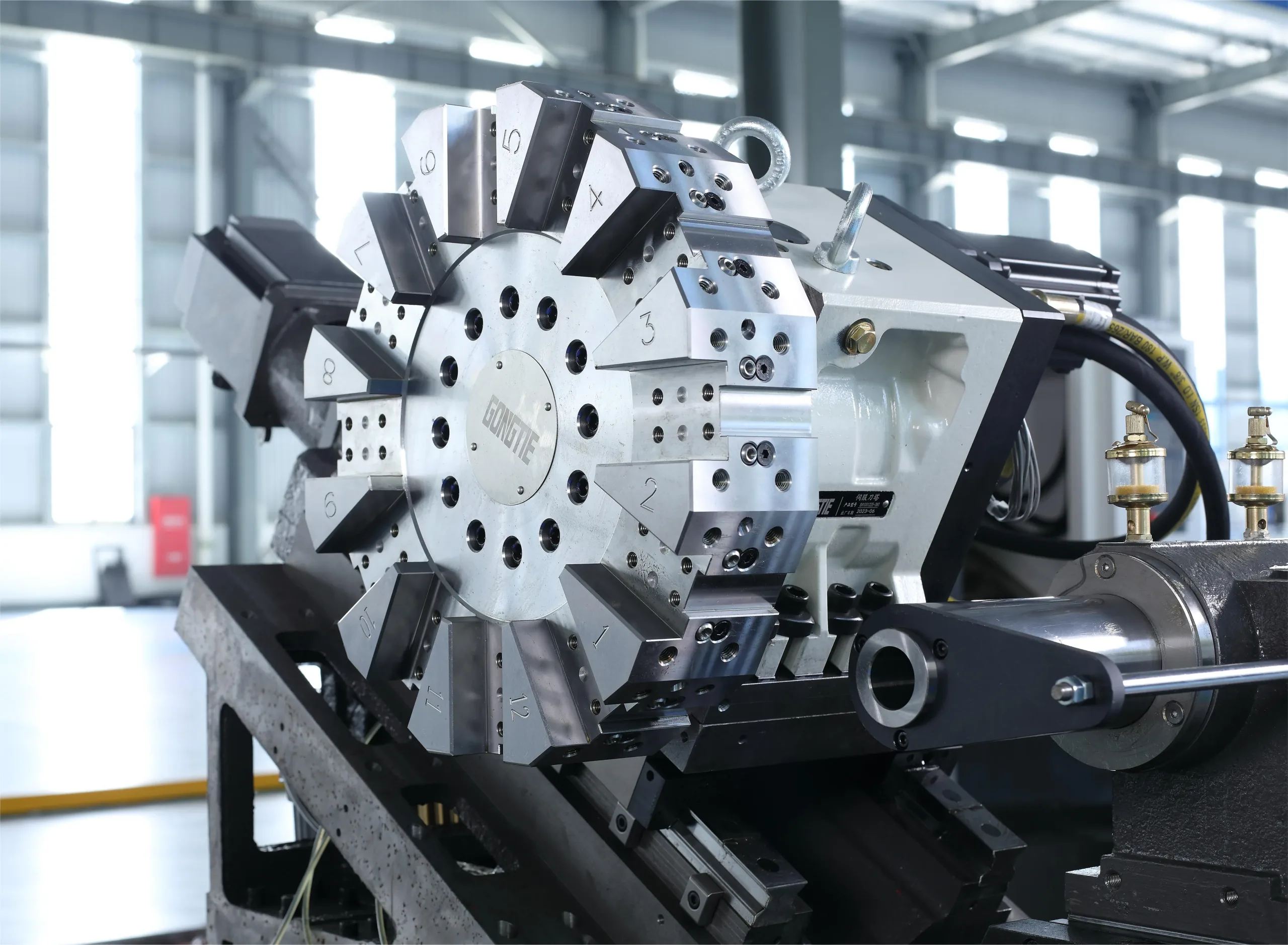

In contrast, a progressive die operates within a single stamping press. It uses a strip of metal fed through sequential stations, each performing a step in the forming process. Punching, bending, and coining are all possible in one continuous movement. This setup allows high-speed output but may result in more visible burrs or taper on part edges.

Tolerances and Edge Quality

When tight tolerances and smooth edges are non-negotiable, fine blanking often proves to be the superior choice. It produces parts with edge characteristics similar to machined surfaces. That makes it ideal for critical applications, such as gears, seatbelt components, and parts of the anti-lock braking system (ABS).

However, a well-designed progressive die can also deliver precision. Especially with added finishing steps or additional stations, a progressive die can achieve impressive consistency. The trade-off lies in edge sharpness and potential secondary deburring. For non-safety-critical components, progressive stamping might offer the perfect balance of cost and quality.

Material and Thickness Considerations

Fine blanking is most effective with softer materials and medium thickness ranges, typically up to 10 mm in thickness. Harder metals can increase tooling wear and reduce die life. Additionally, the materials used must be ductile enough to avoid cracking under triple-action forces.

Progressive die stamping, on the other hand, accommodates a broader range of materials. From thin foil to more complex alloys, this process offers greater versatility. It’s also easier to integrate coatings or laminations, which may not perform well under the delicate blanking process.

Volume, Cost, and Tooling Investment

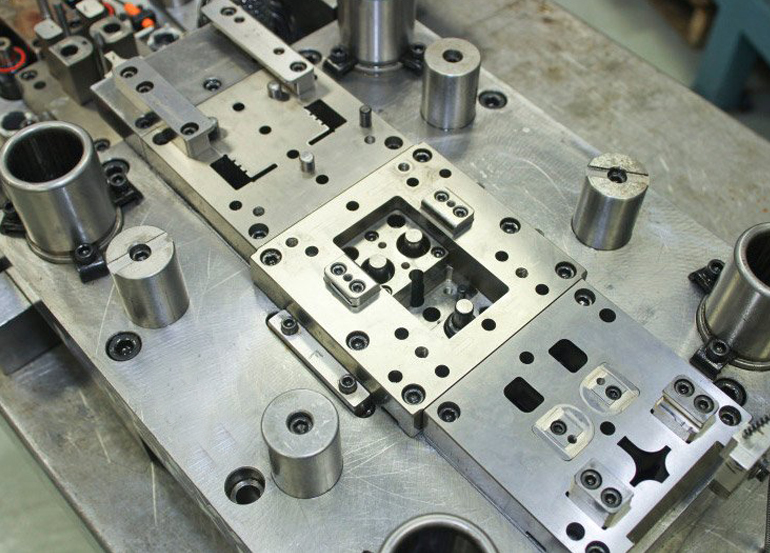

Tooling costs vary significantly between the two methods. Fine blanking dies are more complex and expensive to manufacture. They’re often reserved for high-volume runs where edge quality is paramount. However, the per-part cost may decrease with scale, making the upfront investment worthwhile.

Progressive die tooling tends to cost less and offers faster lead times. It’s also more adaptable to product changes, especially in early production stages. For projects with lower volumes or future design variability, progressive die tooling is a financially sound option.

Part Complexity and Design Flexibility

If your component has undercuts, precise functional surfaces, or needs coining, fine blanking delivers superior dimensional control. It reduces the need for secondary operations and ensures consistent flatness. The downside is limited geometry options compared to progressive die stamping.

Progressive dies excel when parts require multiple forming actions or integrated features, such as tabs, lances, or embossing. Designers can embed various functionalities into a single tool path. That opens up creative freedom while keeping part of the production within a lean framework.

Production Speed and Cycle Time

Fine blanking is slower by nature. The press cycles must accommodate counterpressure and precise material control. Typical speeds range from 20 to 100 strokes per minute. While not slow per se, it’s significantly less rapid than progressive systems.

In contrast, progressive dies thrive at high-speed operation. It’s not unusual to see 300–800 strokes per minute, especially in automated production lines. This makes it ideal for consumer electronics, automotive clips, or any part requiring volume over micro-precision.

Secondary Operations and Post-Processing

Fine blanking usually eliminates the need for secondary machining, deburring, or grinding. Its precision minimises downstream work, saving both time and cost in finishing departments.

Progressive dies may necessitate finishing, depending on the material and edge quality. However, many systems now integrate brushing, in-die tapping, or marking stations. This evolution narrows the gap and makes progressive stamping increasingly self-contained.

Choosing fineblanking and a progressive die based on the application

When choosing between fine blanking and progressive dies, it ultimately comes down to your application priorities. If you are looking for high-edge quality, structural integrity, and tight tolerances, the fine blanking die is more suitable for you. For high-volume, cost-sensitive production with acceptable tolerances, the progressive die is still the best choice.