The manufacture of a metal die involves numerous processes. From rough machining to final polishing, each step affects the die’s performance on the production line. Even minor deviations or poor surface finishes can lead to die wear, defective parts, or costly downtime. Therefore, understanding the machining and finishing methods in Metal die manufacturing is crucial. This helps engineers select the most suitable processes, enhance consistency, and prolong the die’s lifespan in actual production.

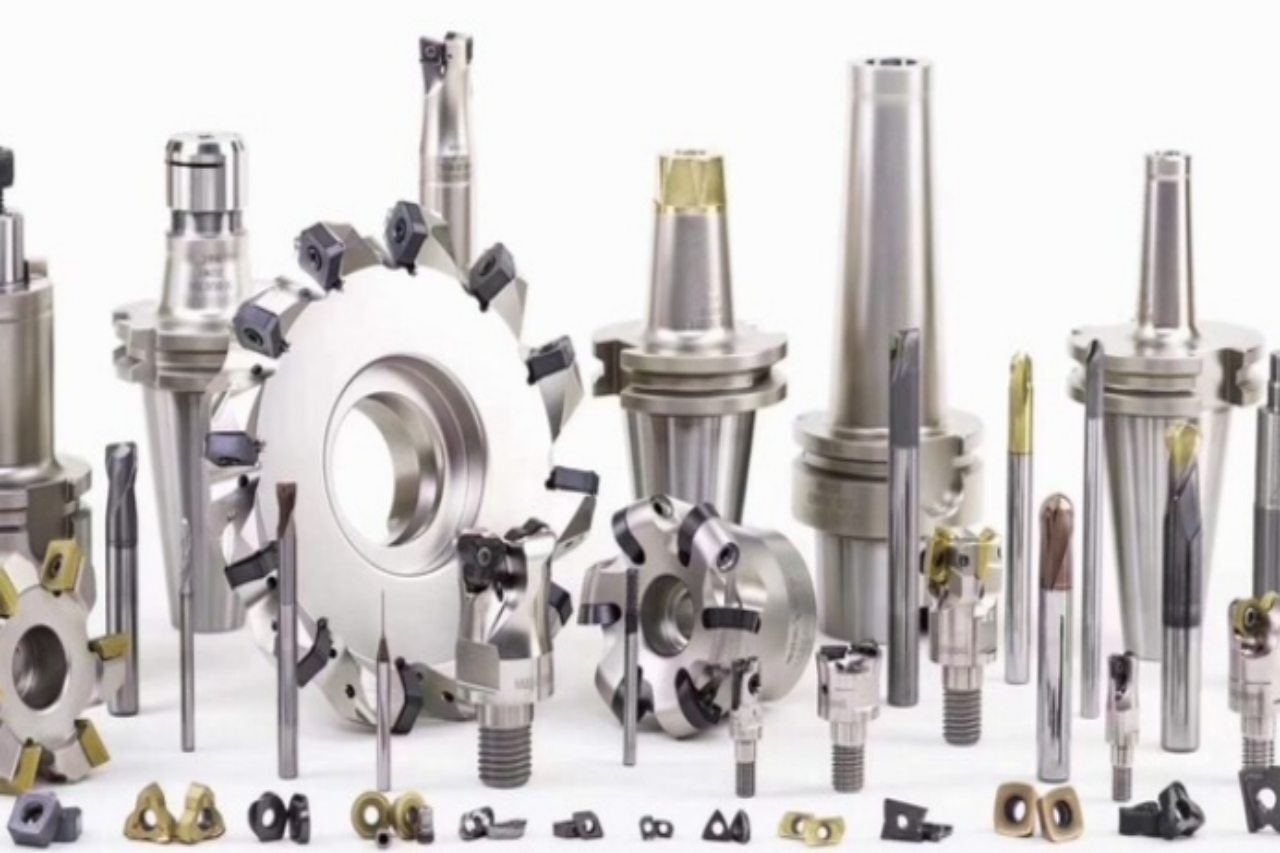

Milling and Turning as the Foundation

Every die starts with basic machining operations. Milling and turning remove large amounts of material, defining the main geometry. CNC milling enables the creation of complex pockets, cavities, and angled surfaces with precision and accuracy. Turning produces shafts, guide pins, and cylindrical parts. Modern multi-axis CNC machines can complete multiple faces in a single setup, saving time and ensuring consistency. These methods provide the foundation on which more specialized processes refine details and accuracy.

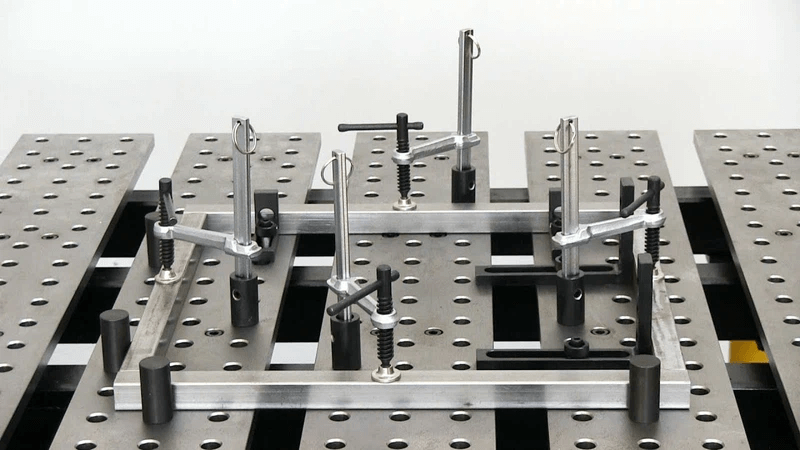

Precision Drilling and Hole Finishing

Accurate holes are the lifelines of any die set. Drilling opens pilot holes, but reaming and precision hole grinding bring them to final dimensions. Precision hole grinding, for instance, can achieve tolerances within ±2 microns, which is crucial for alignment and motion control. In stamping dies, misaligned guide holes can cause tool wear and part distortion. That’s why precision drilling and reaming steps are always followed by inspection using coordinate measuring machines (CMMs). Reliable holes ensure longer tool life and repeatable production results.

EDM Technology for Complex Geometries

Wire EDM and sinker EDM are vital when machining hardened steel or intricate internal features. Wire EDM uses a thin brass wire and electrical discharge to cut shapes without physical contact, avoiding tool pressure and deformation. It’s perfect for tight corner radii and fine details in die inserts. Sinker EDM, utilizing shaped electrodes, creates deep cavities or sharp contours that are impossible to achieve with traditional tools. Both processes can achieve accuracy down to ±1 micron, making them indispensable in modern die shops.

Grinding for Surface and Profile Perfection

After rough machining, grinding brings the final geometry to life. Surface grinding ensures perfectly flat and smooth faces for die plates. Profile grinding replicates complex contours directly from CAD data, maintaining consistency across multiple parts. Jig grinding is used to correct hole position and alignment to within microns. Form grinding produces custom shapes, including radii and grooves, with precision and accuracy. Together, these grinding processes ensure each component fits seamlessly, preventing misalignment during stamping operations.

Fine Surface Finishing for Durability and Appearance

Once geometry is set, surface finishing steps improve both performance and appearance. Polishing removes machining marks and sharp edges, leaving a smooth surface. Lapping achieves mirror-like finishes for contact surfaces, often achieving a roughness average (Ra) of 0.05 µm. Fine surface finishing reduces friction and minimizes material buildup during high-speed production. In industries such as consumer electronics and automotive connectors, smoother die surfaces directly translate to improved product aesthetics and reduced maintenance downtime.

Heat Treatment and Coating for Longevity

Even the most precise machining means little without the right material strength. Heat treatment hardens tool steel, raising wear resistance and impact strength. Processes such as vacuum hardening, nitriding, or cryogenic treatment modify microstructures to enhance stability under thermal cycling. Protective coatings such as PVD, TiCN, or DLC provide additional friction reduction and corrosion resistance. When done right, these treatments can double or triple die life, making them a wise long-term investment for manufacturers.

Advanced and Hybrid Manufacturing Approaches

Modern tooling manufacturers increasingly combine traditional and advanced technologies. High-speed machining removes material faster while maintaining accuracy. Laser texturing and micro-machining create specialized surface textures to control lubrication and part release. Additive manufacturing supports insert production with internal cooling channels that conventional drilling can’t achieve. Hybrid machining centers now integrate milling and EDM functions, cutting setup times, and improving part consistency. These technologies expand what’s possible in precision toolmaking.

The Role of Multiple Processes in Metal Die Manufacturing

Each process plays a specific role in achieving quality, durability, and efficiency. Milling and turning define shape. Grinding and EDM refine accuracy. Finishing and coating ensure performance. By integrating these technologies, manufacturers deliver dies that meet demanding industrial standards. Precision is not the result of one process—it’s the synergy of many. That’s why advanced metal die manufacturing depends on skilled engineers who understand when and how to apply each technique for the best outcome.