Type-C connectors are one of the most widely used interfaces in today’s electronic products. The compact size and versatility make it popular among manufacturers across various industries. However, it has a delicate internal structure, numerous pins, a dense layout, and challenging welding. Additionally, the stamping die tolerances in the manufacturing process are extremely strict. If the stamping dies accuracy does not reach microns, misalignment, part failure, and a significant amount of time and money will be wasted.

Precision requirements for Type-C geometry

Type-C connectors are compact, typically with wall thicknesses under 0.2 mm. Therefore, the stamping die must consistently maintain tolerances in the micron range. Standard deviation in dimensions can lead to functional failures, including poor mating, misalignment, and unstable data transmission.

To achieve this, the die must be designed using high-precision machining and advanced CAD/CAM systems. Every cavity, edge, and profile must be optimized for minimal wear and repeatability. The correct gap between punch and die is crucial—too tight, and you risk rapid wear; too loose, and you compromise accuracy.

Material selection for die longevity

Not all die steels are created equal, especially when dealing with stainless steel or copper alloy sheets commonly used in USB-C components. Tool steels, such as DC53 or ASP23, provide the hardness and toughness necessary to withstand millions of cycles.

Additionally, coatings such as TiCN or DLC can significantly reduce friction and wear, thereby extending the lifespan of the die. Choosing the right material and coating combination means fewer shutdowns and lower long-term costs. A reliable stamping die starts with intelligent material selection.

Die design for burr-free edges

Burrs are the enemy of electrical contacts. For Type-C parts, even the smallest burr can interfere with signal integrity or assembly. That’s why the die must be engineered to minimize burr formation during blanking and forming.

This involves optimizing the shear angle, punch sharpness, and clearance between mating surfaces. Multi-stage progressive dies can also be designed to include a deburring or coining stage, ensuring parts exit the press with a clean finish.

-1024x576.jpg)

Tight strip layout and material utilization

The layout of the strip—the metal sheet as it passes through the die—is a key element in both cost and quality. For small components, such as Type-C contacts, even a 0.1 mm misalignment can cause reject rates to spike.

High-quality stamping dies utilize precise pilot pins, guides, and sensors to ensure alignment. Moreover, optimizing the layout for material usage can reduce scrap, especially when working with expensive materials like beryllium copper. Less waste means higher profitability.

Durability in high-volume production

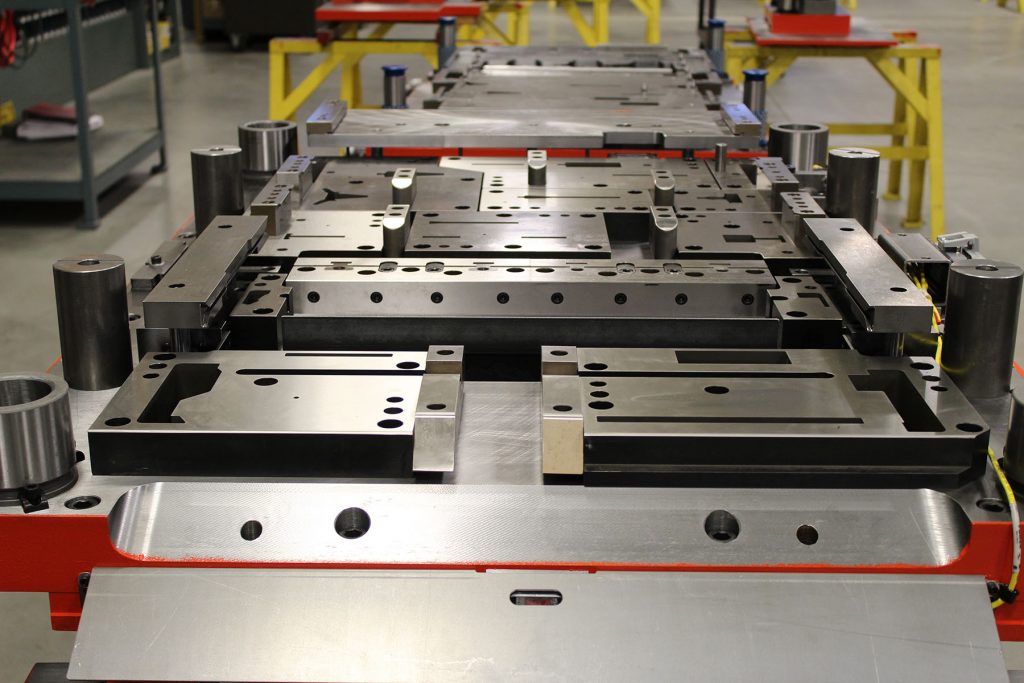

USB-C connectors are produced in massive quantities, so the die must withstand high-speed, high-cycle operation. This places stress on every part of the die, including guides, punches, springs, and strippers.

Advanced die builders use hardened components and precision-ground surfaces to ensure long-term durability. Regular maintenance cycles can be built into the die’s design to minimize downtime. A stamping die built for endurance supports uninterrupted production lines.

Integration with automation systems

In modern facilities, diseases rarely operate in isolation. Instead, they form part of fully automated stamping lines. For USB-C components, automation ensures consistency and reduces labor costs.

A high-quality stamping die includes provisions for sensors, ejectors, and automatic feeding systems. These elements ensure smooth part ejection, real-time quality checks, and alignment correction. Integrated automation reduces errors and boosts efficiency.

Quality control and stamping dies validation

Building the die is only half the equation—validating its performance is equally important. Manufacturers must perform pre-article inspections, capability studies, and pilot runs to ensure that the stamping die meets performance criteria.

Inspection methods, such as vision systems or laser measurement tools, help catch defects before full-scale production begins. Documentation and revision control also play a role. A validated stamping die provides confidence and data-backed assurance.

Choosing the proper stamping die facilitates the manufacturing of USB-C parts

In USB-C production, it is crucial to see the precision stamping die. It determines whether the output is smooth because even a slight deviation may cause part scrapping and waste of resources. Choosing the right material and design, combined with strict quality control, can help maintain stable production and minimize waste.