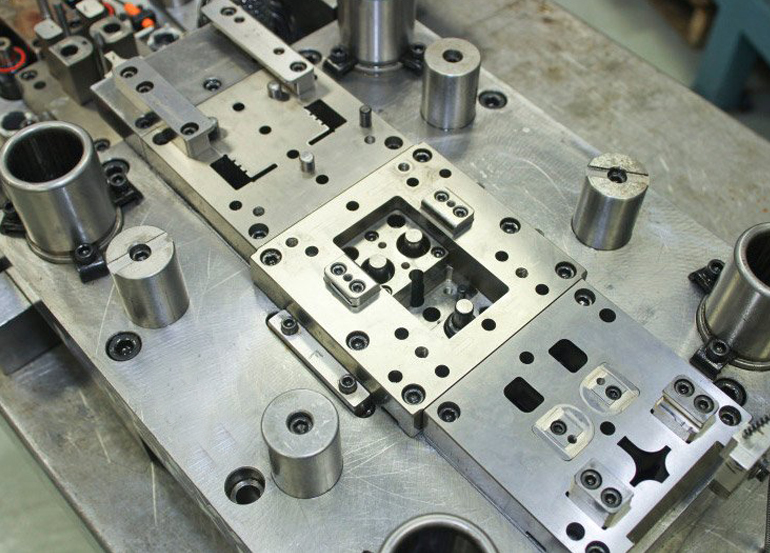

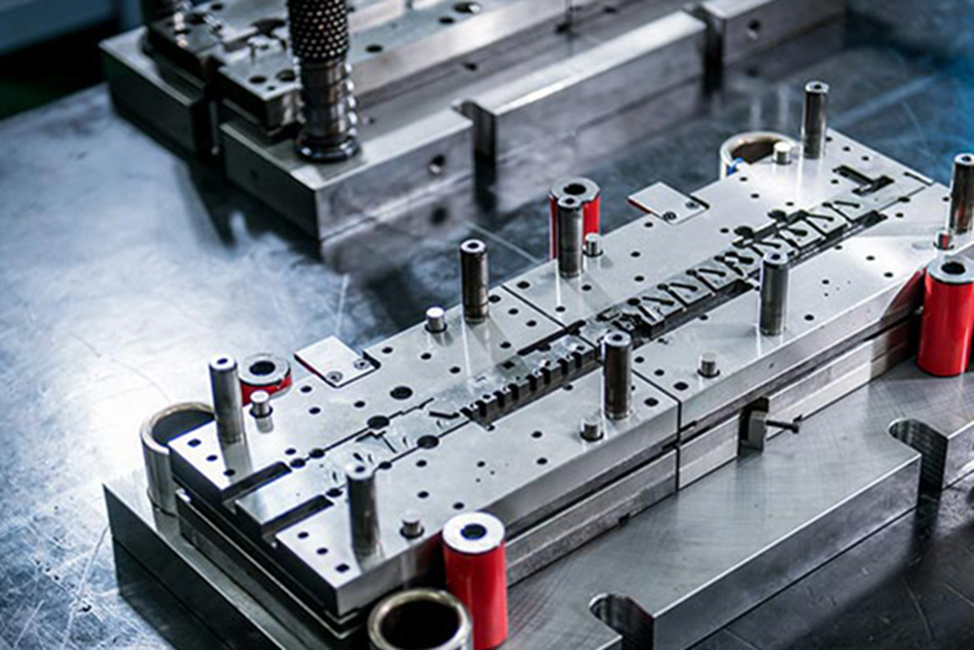

In stamping die design, the die base plays a critical structural role. It supports inserts, guides alignment, and absorbs forming forces. Traditionally, steel or cast iron dominated this space. However, tooling demands have changed. Faster development cycles, lower production volumes, and tighter budgets pushed manufacturers to explore alternatives. This shift explains why engineers increasingly discuss the Plastic Die Base. A Plastic Die Base uses high-strength engineering plastics instead of metal for the base structure. These plastics typically include glass-fibre-reinforced epoxy, phenolic composites, or polyurethane-based tooling boards. They do not replace cutting inserts. Instead, they support them. This distinction matters. Engineers should not confuse plastic bases with soft tooling. Modern Plastic Die Base solutions are designed for real industrial use, not lab experiments.

How Plastic Die Bases Are Manufactured

Manufacturers produce plastic die bases through precision casting, compression moulding, or CNC machining of composite blocks. Material selection defines performance. Glass-filled epoxy provides stiffness and thermal stability. Phenolic composites deliver wear resistance and vibration damping. Some systems combine layered materials to achieve optimized strength.

After curing, manufacturers machine these bases to tight tolerances. They add guide pin holes, mounting surfaces, and insert pockets just like metal bases. From a dimensional standpoint, a well-made Plastic Die Base behaves predictably. It holds alignment. It supports inserts. It fits standard presses. The difference lies in weight, machinability, and cost structure.

Key Mechanical Characteristics to Know

Plastic dies have a lower density than steel. This feature dramatically reduces tool weight. Lighter tools simplify handling, reduce press wear, and speed up changeovers. Many plants value this advantage more than raw strength.

Plastic materials also dampen vibration better than metal. Reduced vibration improves part consistency in light stamping operations. Additionally, plastics resist corrosion. Humid environments, coolant exposure, and storage conditions cause fewer problems.

However, plastics have lower compressive strength than steel. They also deform under sustained high loads. Engineers must carefully evaluate tonnage, stroke rate, and contact pressure. Plastic Die Base designs work best when forces remain controlled and predictable.

Where Plastic Die Bases Make the Most Sense

Plastic die bases shine in low-volume production. Prototyping programs benefit immediately. Automotive suppliers often use them during early validation phases. Electronics manufacturers rely on them for thin material stamping. Appliance makers adopt them for pilot tooling.

Short-run production also fits well. When annual volumes stay below tens of thousands of strokes, Plastic Die Base solutions perform reliably. They reduce upfront cost. They shorten lead times. They simplify design changes. Toolmakers also use them for backup or bridge tooling. When final steel tooling is not ready, plastic-based tools keep production moving without considerable investment risk.

Situations Where Plastic Die Bases Fall Short

Plastic die bases are not universal solutions. High-tonnage progressive dies push beyond their comfort zone. Deep-drawing operations generate sustained compressive loads that plastics cannot withstand in the long term. High-speed stamping lines also introduce thermal buildup and fatigue risks.

If tooling requires extreme rigidity, steel still wins. Long production runs demand predictable wear behaviour over millions of strokes. Plastic Die Base systems cannot compete in these scenarios. Choosing them incorrectly leads to deformation, misalignment, or premature failure.

Cost, Lead Time, and Modification Advantages

Cost is a major driver of interest in plastic die bases. Material prices remain lower than tool steel. Machining time drops significantly. Toolmakers often report base fabrication 30–50% faster. These savings matter during early design stages.

Modification is another advantage. Engineers can re-machine plastic bases easily. Design iterations become less painful. Adding pockets, changing layouts, or relocating inserts requires less effort than reworking hardened steel. For companies running agile development cycles, Plastic Die Base tooling aligns well with modern manufacturing strategy.

Design Considerations Engineers Should Not Ignore

Design discipline still matters. Engineers must distribute loads evenly. They should use steel wear plates in high-contact zones. Insert interfaces require reinforcement. Guide components must remain rigid. Mounting methods also deserve attention. Over-tightening fasteners damages plastic structures. Designers should follow torque specifications closely. Proper backing plates prevent localized crushing. A Plastic Die Base succeeds when designers respect material limits. Poor design choices cause most failures, not the material itself.

Final Thoughts on When to Choose a Plastic Die Base

A Plastic Die Base is not a downgrade. It is a strategic choice. It excels in prototyping, pilot runs, and low-volume production. It reduces cost, shortens lead time, and simplifies handling. It supports modern, flexible manufacturing workflows. However, it does not replace steel tooling for heavy-duty applications. Engineers should honestly evaluate tonnage, stroke count, and longevity requirements. When applied correctly, plastic die bases deliver real value. When misused, they fail fast. Smart tooling decisions match the tool to the job. In many cases today, a Plastic Die Base is precisely the right fit.