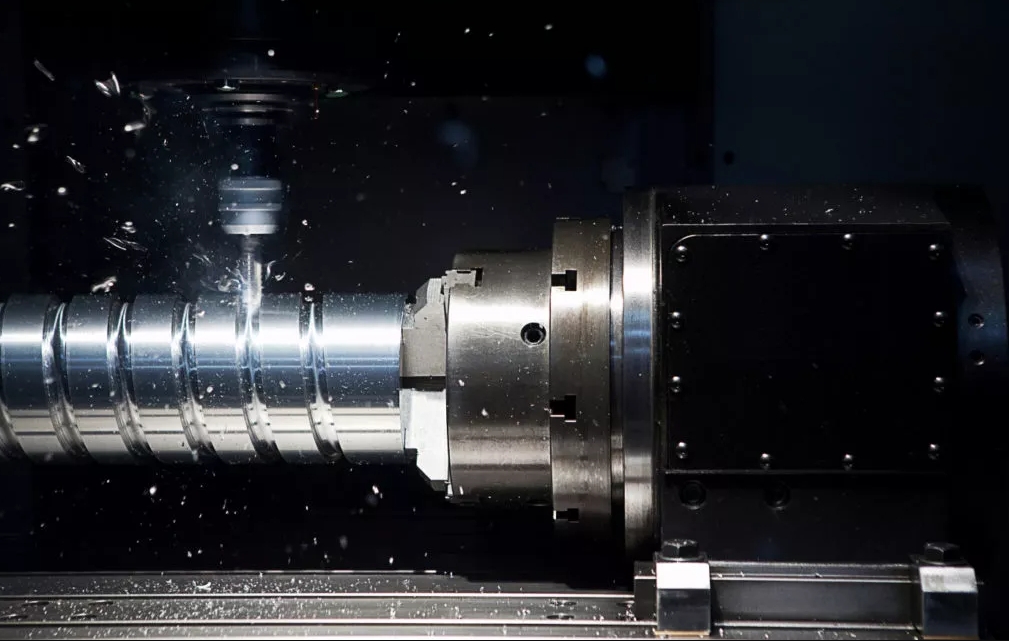

The effect will be better if precision equipment is used for processing. How can this be said? First, the processing effect is much faster, and then the processing power is much faster. In addition, smart devices are constantly increasing, and automation is becoming more and more obvious. Therefore, the requirements for skills in CNC gong processing and milling machine processing are getting higher and higher. CNC gong processing is to process products, use computers with digital control systems, and set up more precise processing and production. Compared with traditional mechanical processing, the power or quality of modern CNC gong processing is better than traditional manual prototypes.

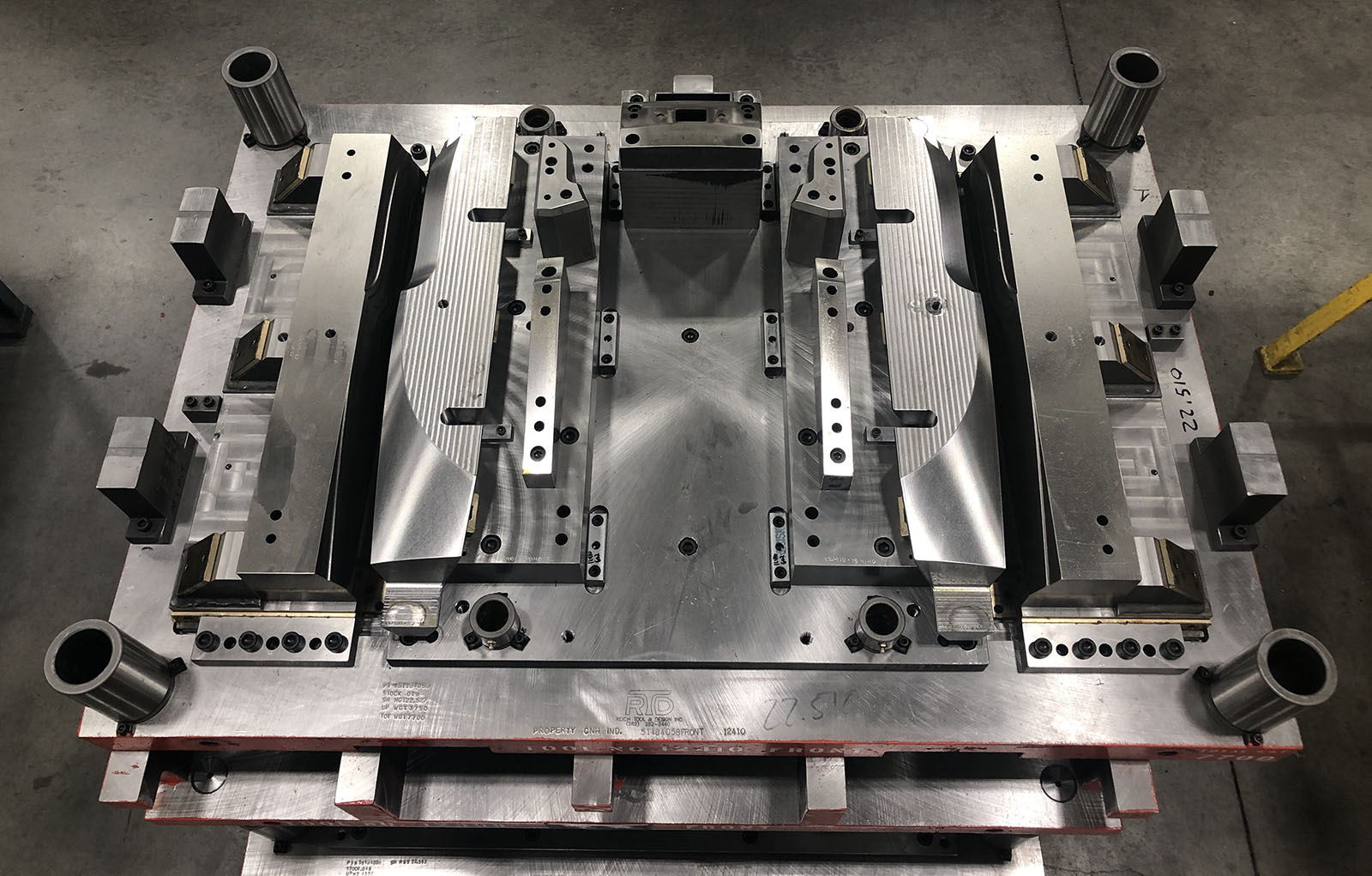

With the continuous development of computer technology, processing equipment can process more parts at the same time. CNC equipment now has a great integration advantage than before and has become the mainstream processing method now. The advantage of CNC prototype is that it can accurately reflect the information expressed in the drawing, and the surface quality of CNC prototype is high, especially after the surface spraying and silk screen printing are completed, it is even more dazzling than the products produced after the mold is opened. Therefore, it is not unreasonable that more and more people choose CNC prototype processing and production.

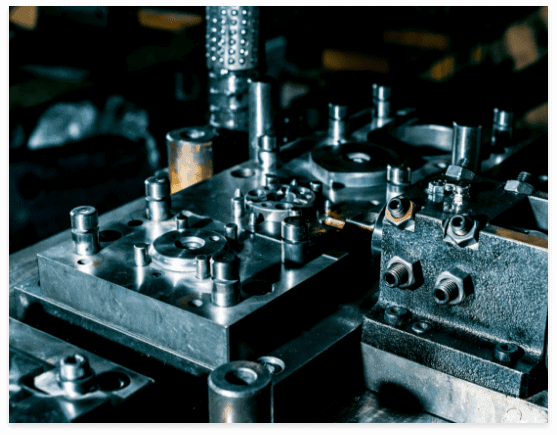

1. The precision and surface roughness of CNC prototype parts: If the tolerance requirement is 0.05mm, the requirements for both processing equipment and prototype masters are relatively high, and the cost will be much higher;

2. If the material of the CNC prototype parts is difficult to process, such as stainless steel, the material hardness is high, and tungsten steel hardened tools are required, and the CNC gong needs to be made by Taiwan or Japanese machines. Of course, the cost will be higher than that of general materials.

3. The structure and size of CNC prototype parts: If the product structure is messy, the processing cost will be much higher; if the overall size of the product is large or the appearance is a curved surface, the processing cost will also increase a lot.