In the early days of stamping die production, most manufacturers operated like skilled craft workshops. Results depended heavily on individual toolmakers. Knowledge lived in people’s hands, not in documented systems. This model worked when part geometries were simple and tolerances were forgiving. However, consistency suffered once production volumes increased or designs became more complex. Modern stamping die manufacturers operate under a very different mindset. Engineering systems now define outcomes before steel is ever cut. Design standards, material databases, and press parameters guide every step. This shift transformed die making from experience-driven craftsmanship into repeatable industrial engineering. The result is predictable quality across programs, facilities, and production cycles.

Design Engineering Has Replaced Incremental Guesswork

Traditional die design relied on 2D drawings and experience-based assumptions. Engineers often finalized layouts without full visibility into forming behavior. Issues such as tearing, wrinkling, or springback surfaced only during tryout. Fixes followed a trial-and-error loop, increasing lead time and cost.

Modern manufacturers design dies within fully integrated 3D CAD environments. Engineers simulate strip progression, forming strain, and material flow before machining begins. Virtual validation reduces physical iterations significantly. This proactive approach allows stamping die manufacturers to support thinner materials, higher-strength alloys, and tighter tolerances without sacrificing stability.

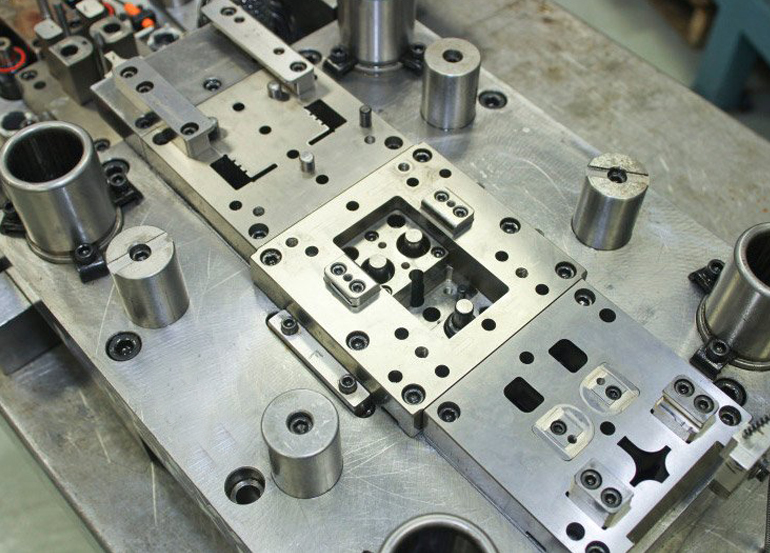

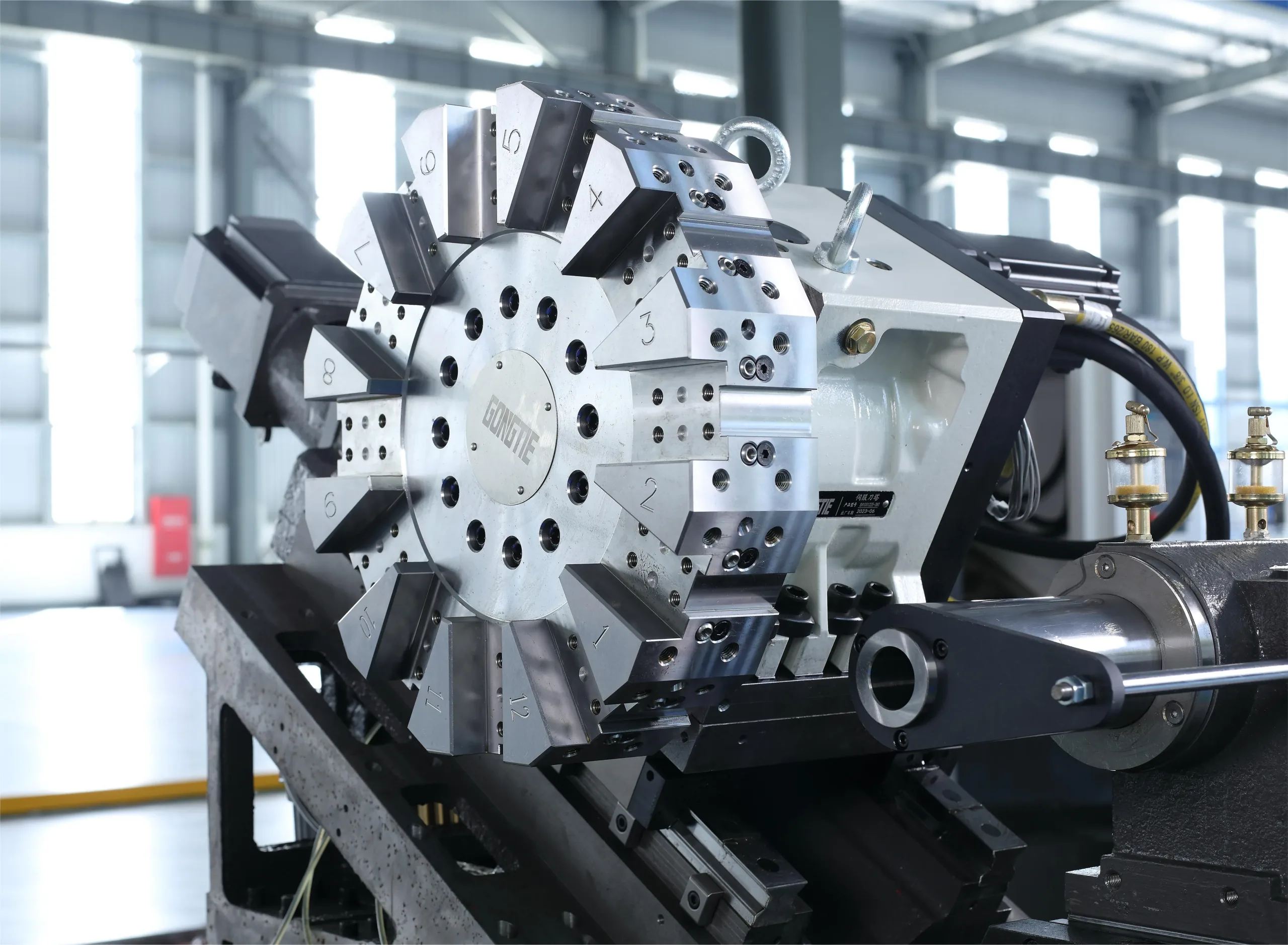

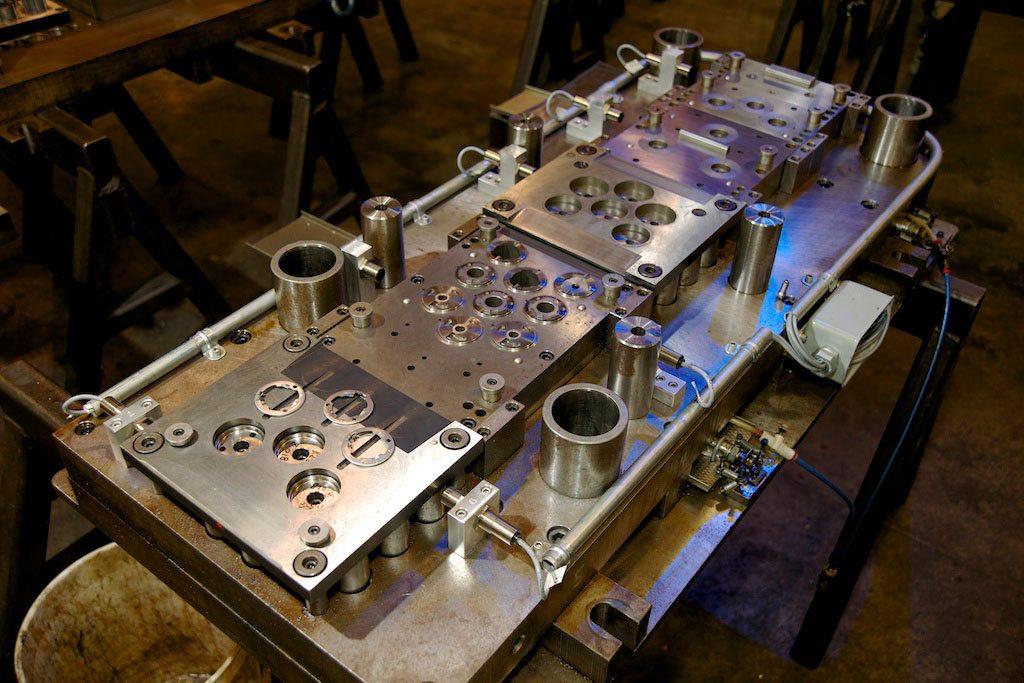

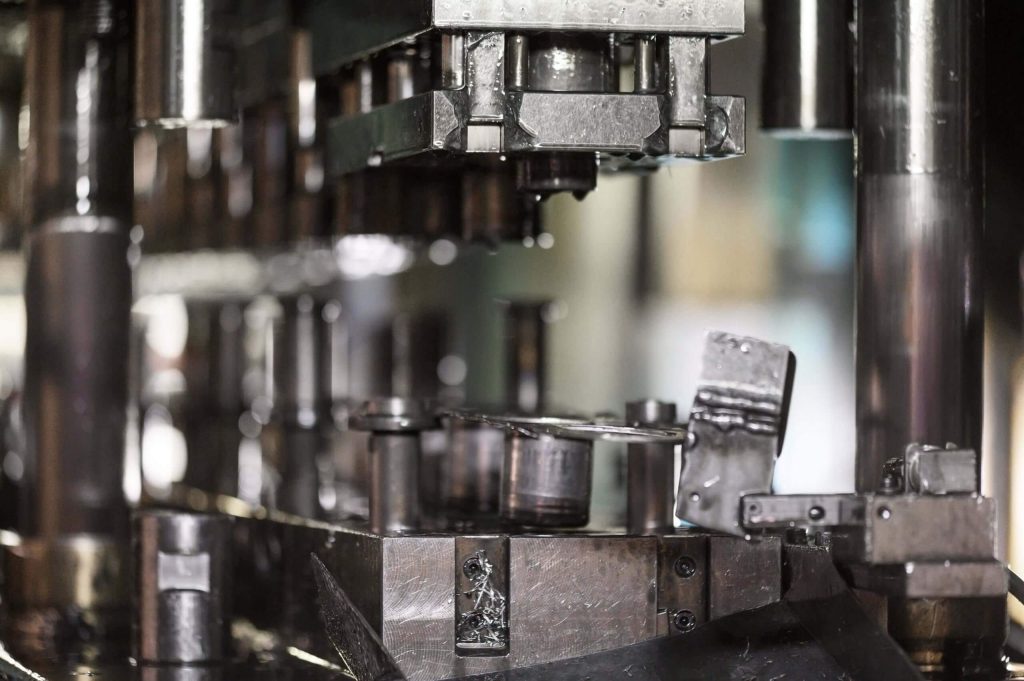

Machining Technology Now Enables Consistent Precision

Older die shops depended on conventional milling, surface grinding, and manual fitting. Accuracy varied with operator skill and machine condition. Complex contours required extensive handwork. Maintaining consistency across multiple die sets was difficult.

Modern stamping die manufacturing uses high-speed CNC machining, wire EDM, and multi-axis equipment as standard tools. Machines cut components directly from validated CAD data. Precision improves, but repeatability matters more. Modern stamping die manufacturers can reproduce identical die components across different projects and timelines, supporting long-term production consistency.

Tool Steel Selection Became a Strategic Decision

Historically, tool steel choices followed habit rather than analysis. Shops reused familiar grades based on availability and experience. This approach struggled as part of the materials evolved. High-strength steels and coated sheets increased wear and failure risk.

Modern manufacturers select tool steels based on production volume, forming severity, and maintenance strategy. Engineers evaluate hardness, toughness, and machinability together. Heat treatment parameters align with expected load conditions. These practices allow stamping die manufacturers to extend die life while reducing unplanned downtime and repair frequency.

Process Control Reduced Dependence on Press-Side Adjustments

Traditional tryout phases involved repeated press adjustments. Teams corrected issues as they arose, often without a thorough root-cause analysis. This reactive method consumed time and introduced variability into production ramp-ups.

Modern manufacturers control processes from design through validation. Simulation predicts forming behavior. Coordinate measurement systems verify component accuracy. Tryout focuses on confirmation rather than discovery. With tighter control, stamping die manufacturers reduce launch risk and achieve stable output earlier in the production cycle.

Customer Collaboration Has Become an Expected Capability

In the past, customers accepted limited transparency. Communication often occurred late, after problems emerged. Documentation remained minimal.

Today’s customers expect early technical involvement. They want manufacturability feedback before the design freeze. They demand clear timelines, measurable progress, and data-backed decisions. Modern stamping die manufacturers operate as engineering partners, aligning tooling strategy with part function, material choice, and press capability. This collaboration shortens development cycles and improves the quality of the final parts.

Digital Integration Changed How Manufacturers Scale

Traditional die shops scaled through labor. Growth required hiring more skilled workers, which limited expansion. Knowledge transfer remained informal and inconsistent.

Modern manufacturers scale through digital systems. Automation supports machining, inspection, and documentation. Process data remains traceable across projects. Digital records preserve design intent and lessons learned. These capabilities allow a stamping die manufacturer to manage multiple complex programs without sacrificing quality or responsiveness.

Choosing Between Traditional and Modern Stamping Die Manufacturers

The difference between traditional and modern operations continues to widen. Experience still matters, but systems now amplify expertise. Buyers who choose suppliers based solely on cost often face long-term inefficiencies. Modern stamping die manufacturers deliver predictable performance, scalable capacity, and engineering depth. They reduce risk during product launches and support evolving material demands. In today’s competitive manufacturing environment, these differences directly impact total cost, lead time, and product reliability.