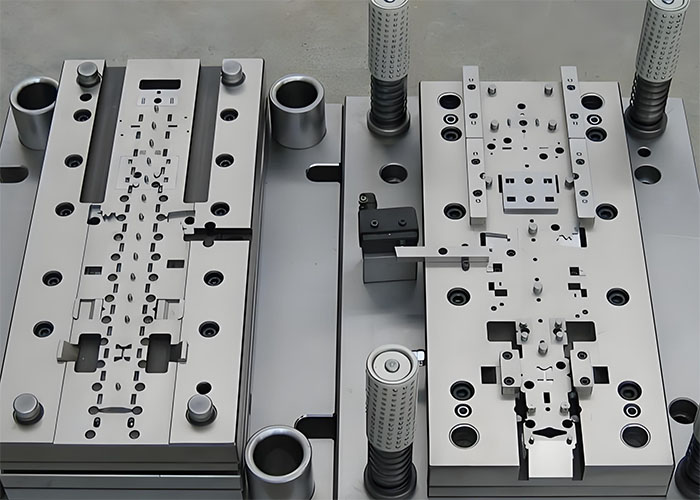

For the precision control of precision dies, we don’t simply view it as a single step, but rather as a controlled process that begins with the design intent and extends through every stage, including material selection, machine tool performance, fixtures, process control, and inspection. Achieving a precision die accuracy of ±0.002 mm is highly challenging, but it is entirely achievable if engineers combine the right equipment, mature process solutions, and rigorous quality assurance. Therefore, we will introduce the practical technologies employed by Chaoyang—high-speed YASDA machining, large-capacity AWEA/AGMA/Vision Wild machining centers, fine-wire electrical discharge machining (φ0.05-0.30 mm), and ultra-precision grinding and fixtures—to produce dies that meet the flatness, roundness, and geometric accuracy requirements of modern precision manufacturing.

Precision Dies: Design, Materials, and Dimensional Intent

Successful tolerance control begins at the design stage. When engineers specify precision dies with an accuracy of ±0.002 mm, they must translate functional requirements into geometric tolerances that the manufacturing process can reliably replicate. First, identify the critical datums, mating relationships, and surface finishes that affect part function. Second, select die materials with low, well-defined coefficients of thermal expansion and stable metallurgical properties—engineers commonly choose tool steels such as A2, D2, and high-quality H13 because they maintain dimensional stability after heat treatment and resist deformation during electrical discharge machining and grinding.

Equally important, designers should specify reasonable geometric tolerances: reserve ±0.002 mm tolerances for features that directly impact part function or stack-up. Use Geometric Dimensioning and Tolerancing (GD&T) to reduce ambiguity; specify positional tolerances, concentricity, and perpendicularity relative to stable datums. In design reviews, our manufacturing and metrology teams ensure that existing processes can achieve the required tolerance stack-up. Finally, document surface finish targets (e.g., Ra0.05 where applicable), as surface texture affects contact interactions and inspection methods.

High-Speed, Large-Size CNC Machine Tools with ±0.002 mm Accuracy

The choice of machine tools determines whether the ±0.002 mm accuracy target is feasible. Achieving this level of precision requires two complementary types of machine tools: high-speed, ultra-rigid multi-axis machining centers for processing miniature features; and large, heavy-duty CNC machining centers for processing significant die components. At the Chaoyang factory, we use high-speed CNC from YASDA in Japan, with spindle speeds up to 40,000 rpm. These machines excel in micro-geometry machining, fine surface finish, and precise shape control because their spindle dynamics, thermal compensation, and structural rigidity minimize runout and vibration.

For larger workpieces, our AWEA/AGMA/Vision Wild CNC machining centers provide the necessary machining capacity and thermal stability. These machines focus on structural strength, thermally controlled axes, and advanced drive systems to maintain tolerances while removing more material. Key machining practices include frequent warm-up cycles, active thermal compensation, minimal tool overhang, and careful programming to avoid abrupt changes in machining direction. Crucially, process engineers match these machines with high-quality tooling (sharp carbide or CBN inserts for fine machining) and optimized cutting parameters to reduce cutting forces that lead to elastic deformation.

Wire EDM and Micromachining for Precision dies – Accuracy to ±0.001 mm, Surface Roughness Ra 0.05

When complex contours, small radius corners, or thin punches need to be machined, wire electrical discharge machining (EDM) becomes indispensable. Chaoyang’s wire EDM capabilities utilize wires ranging from φ0.05 mm to φ0.30 mm in diameter, enabling the cutting of delicate shapes with extremely high geometric accuracy. Since EDM is a thermal process, controlling spark energy, pulse duration, and flushing is critical to minimizing recast layers and maintaining dimensional accuracy.

Fine-wire EDM with φ0.05–0.10 mm wires allows for cutting internal features with minimal kerf and microscopic radii, achieving dimensional repeatability as low as ±0.001 mm with strict control of process parameters and electrode wear compensation. Another advantage of electrical discharge machining (EDM) is its excellent surface finish: by sequentially performing roughing, semi-finishing, and finishing operations and applying low-energy finishing pulses, we can consistently achieve surface roughness near Ra0.05. Subsequent post-EDM processing—such as light grinding, polishing, or vibratory finishing—can remove any remaining recast layer and further improve surface integrity.

Fixturing, Coordinate Grinding, and Shape Control, with Accuracy to ±0.001 mm

Even the best machine tools cannot achieve ±0.002 mm accuracy without precision fixturing and controlled grinding. Fixtures must establish stable, repeatable datums to resist clamping deformation. At Chaoyang, we design dedicated fixtures that distribute clamping forces evenly and, where feasible, employ kinematic positioning to minimize over-constraint. For thin or asymmetrical precision dies, we use multi-point support plates and controlled-torque clamping to prevent elastic bending under load.

Coordinate grinding and surface grinding processes provide final dimensional and shape control. We use CNC surface and cylindrical grinders equipped with in-process probing to correct residual deviations and control the roundness and positional tolerances of holes, slots, grooves, and contours to within ±0.001 mm. For example, we combine centerless grinding for cylindrical features and use diamond grinding wheels for hardened surfaces. Intermediate stress-relief and stabilization treatments between machining and grinding operations reduce residual stresses that would otherwise cause dimensional deformation over time.

Process Control, Thermal Management, and die Strategy

Maintaining ±0.002 mm accuracy requires rigorous process control. Temperature is a significant obstacle—fluctuations in ambient temperature and heat generated during cutting can cause micron-level dimensional changes. To overcome this, we maintain strict control of the workshop environment during precision machining phases, instrumentally monitor machine tool and workpiece temperatures, and implement thermal drift compensation in the CNC system. In addition, we have optimized the machining sequence to minimize heat accumulation: finish machining is scheduled after rough machining, and the holding-pressure stage, and the thermal stabilization treatment is performed after high-energy machining, followed by precision machining.

Tooling strategy also impacts tolerance control. High-precision tool holders (HSK, shrink-fit) are used, and runout is minimized through spindle and tool balancing. Tool life tracking is implemented, and tools are replaced before wear exceeds the threshold.

Achieving ±0.002 mm accuracy

Achieving ±0.002 mm accuracy in precision dies does not rely on a single piece of equipment or process, but rather stems from a complete precision die manufacturing process. Accurate tolerance control depends on the synergistic cooperation of design intent, material stability, advanced CNC machining, fine wire EDM, ultra-precision grinding, and rigorous metrological inspection. By utilizing high-speed YASDA CNC machine tools, large AWEA/AGMA/Vision Wild machining centers, micro-wire EDM equipment with accuracy up to ±0.001 mm, and precision fixtures and coordinate grinding technology, Chaoyang consistently delivers precision dies that meet the most stringent dimensional requirements.