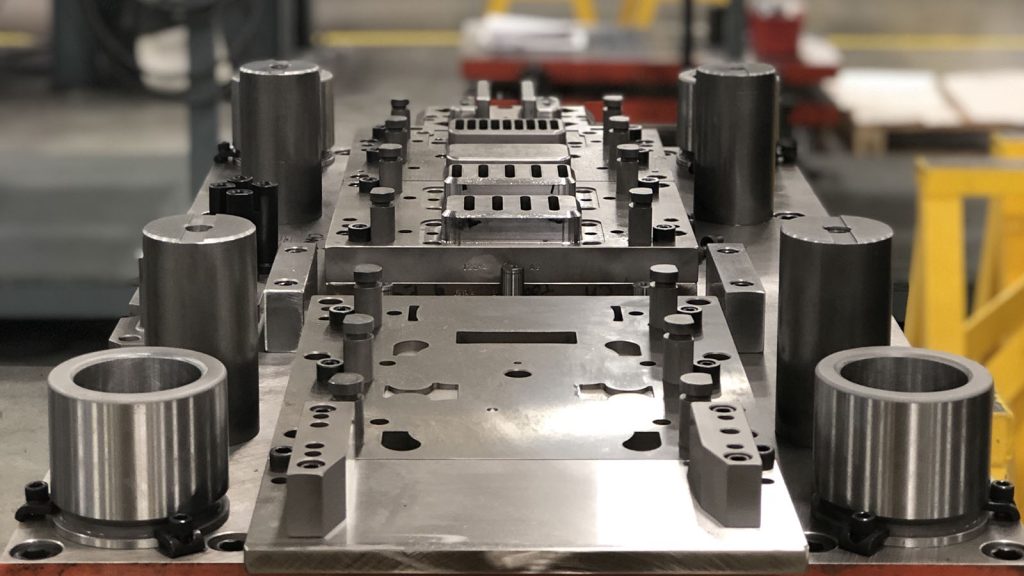

Metal dies play a critical role in achieving efficiency, precision, and repeatability in high-volume electronics manufacturing. From producing microminiature connectors to complex shielding components, metal dies form the foundation for scalable production.

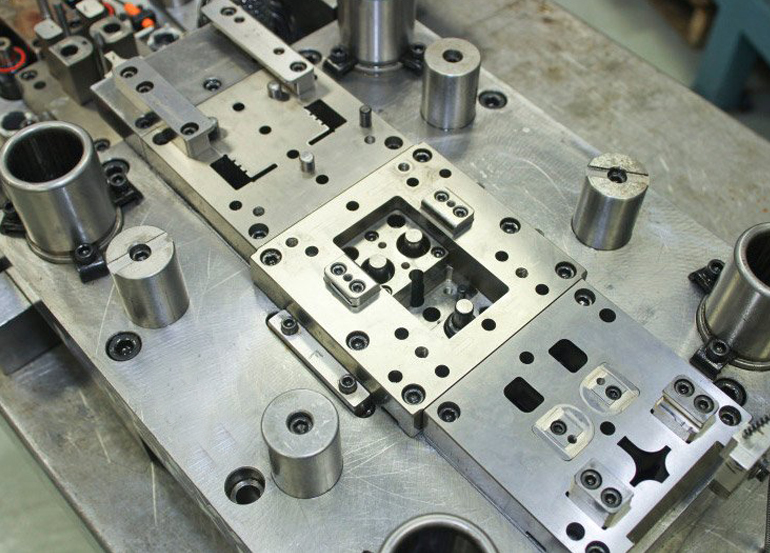

Precision and Repeatability in Stamping Processes

Metal Dies allow manufacturers to replicate intricate parts with micrometre-level precision. This consistency is crucial when producing connectors, terminals, and enclosures for devices such as smartphones and wearables. By minimising variability, metal dies help ensure product compatibility and functionality.

Repeatability also reduces waste. Each stroke of a high-speed press delivers identical results, making it possible to meet massive output quotas without compromising quality. With fewer defects and consistent part dimensions, downstream processes like assembly and quality inspection become faster and more reliable.

Customisation for Specific Applications

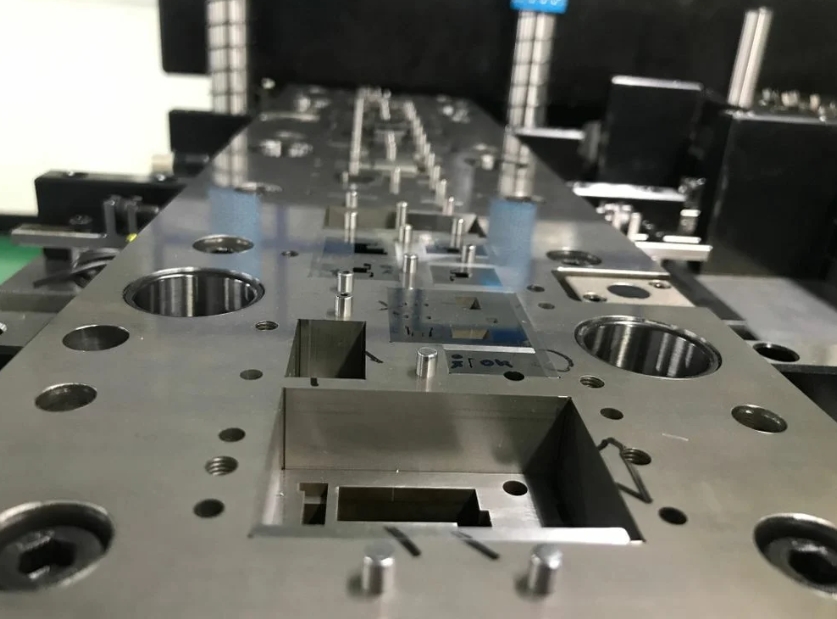

Not all electronic components are created equal, which is why die customisation matters. Metal Dies can be engineered to accommodate special features, such as multiple bend angles or tiny embossments. This flexibility enables designers to innovate without being constrained by tooling limitations.

Additionally, custom dies are used to improve integration between mechanical and electrical systems. When dies are tailored to specific PCBs or housing components, it leads to better fit, function, and overall product integrity. In turn, OEMs gain a competitive edge by offering more compact and advanced devices.

Material Selection and Die Durability

The performance depends heavily on material selection. Tool steels, such as SKD11 or DC53, offer wear resistance and toughness, which are essential for high-volume production. Coatings like TiN or DLC can further extend die life, reduce maintenance, and improve part surface finish.

Choosing the right materials also affects the total cost of ownership. While premium alloys and coatings may increase upfront costs, they often result in lower downtime and fewer replacements. In fast-paced electronics production, this trade-off is well worth it.

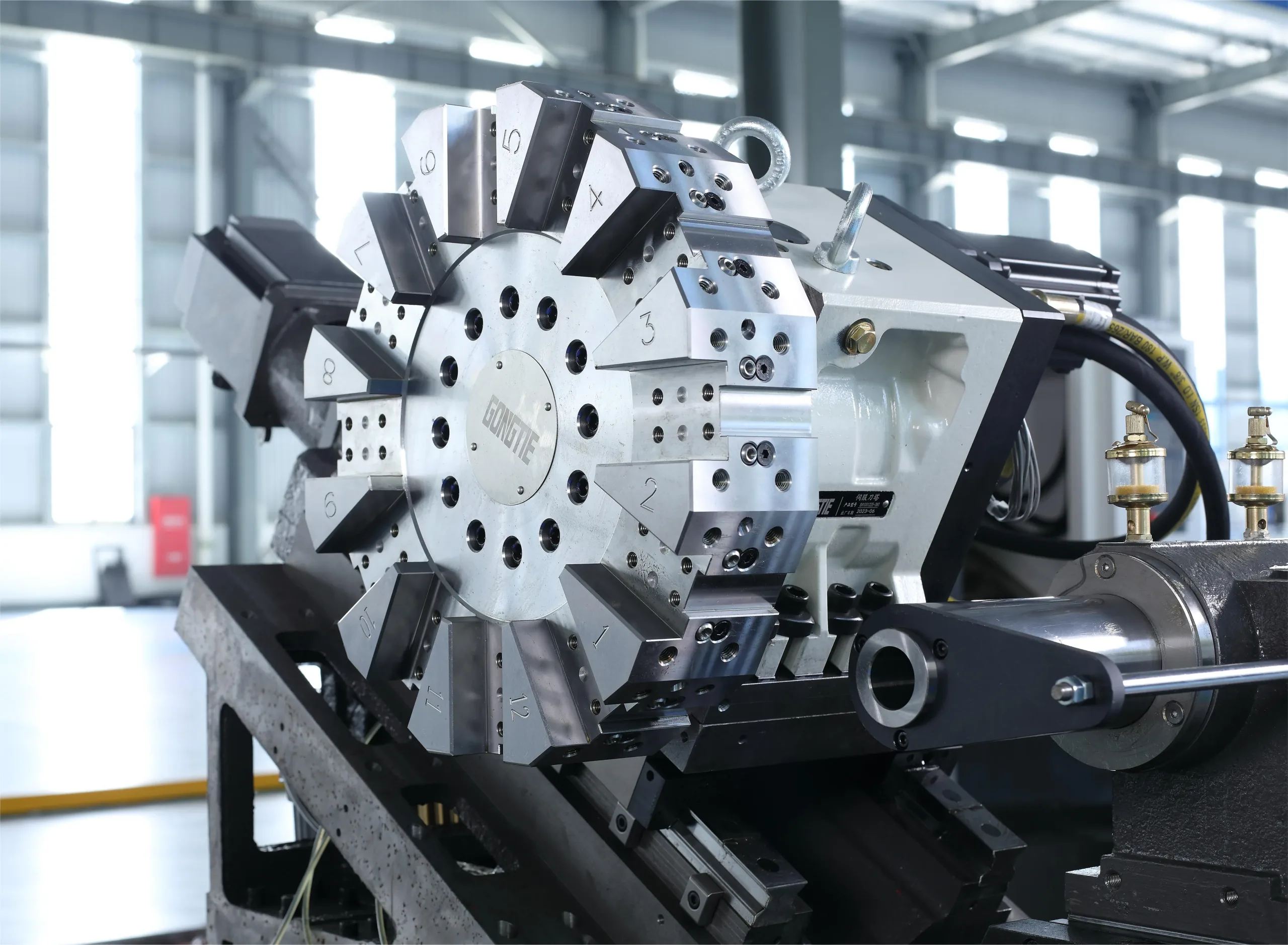

Speed and Automation in High-Volume Manufacturing

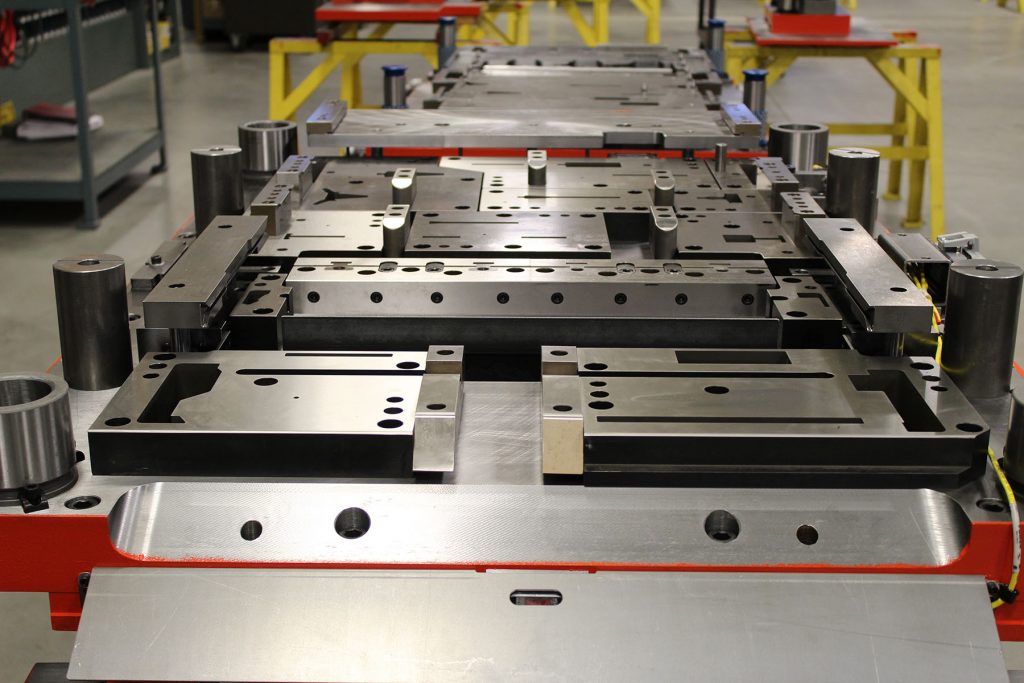

Metal Dies are designed for speed. When paired with servo-driven presses or automated feeding systems, they enable cycle times of milliseconds per part. This is crucial in electronics markets, where time-to-market can define success.

Moreover, dies that support progressive stamping can combine multiple forming actions in a single press stroke. This reduces handling, simplifies logistics, and maximises throughput—all without sacrificing quality. Automation-ready dies are now standard in leading production environments.

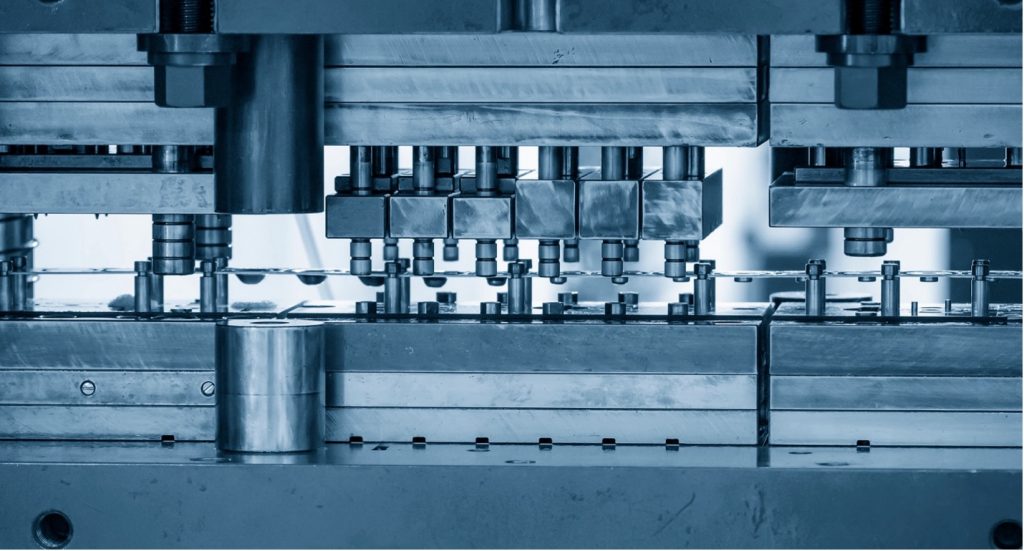

Quality Assurance and Tolerance Control

Maintaining quality at scale requires rigorous control of tolerance. Metal Die delivers predictable results, which simplifies statistical process control and reduces the need for frequent inspections. This boosts yield and keeps production lines running smoothly.

Innovative die systems now integrate sensors to monitor wear, misalignment, and pressure variations in real time. These features help detect issues before they become defects, further improving reliability. The result is a proactive approach to quality that benefits the entire supply chain.

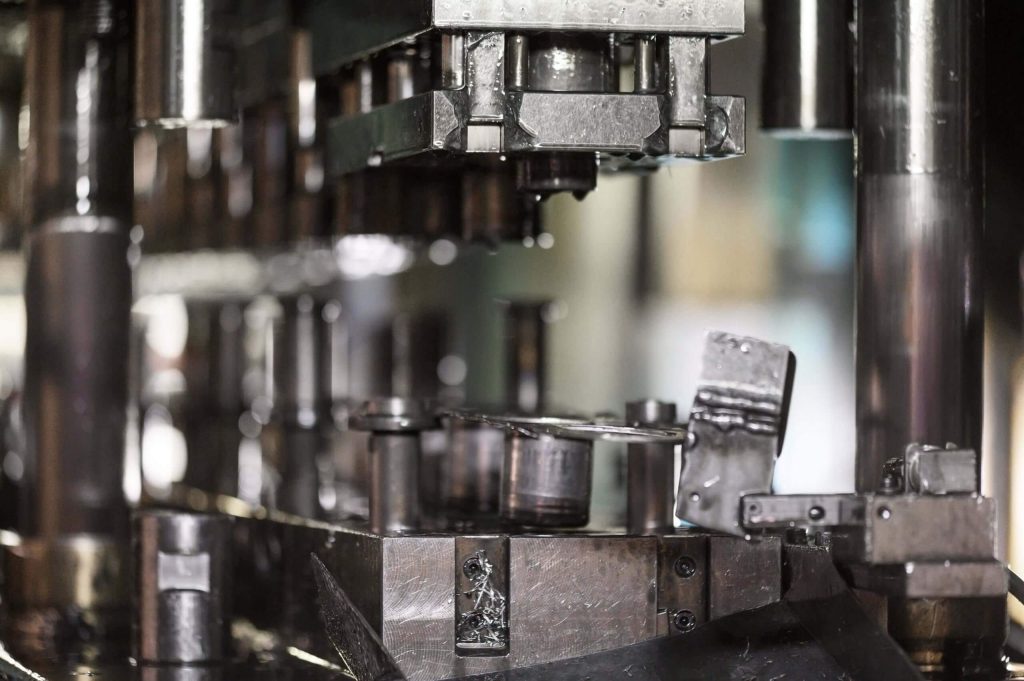

Tooling Maintenance and Lifecycle Management

Even the best require regular maintenance. Preventive maintenance programs—such as sharpening, cleaning, and recoating—ensure that dies continue to perform optimally. Skipping maintenance risks premature wear, part defects, and costly downtime.

Lifecycle management also matters. Manufacturers must track tool usage, cycle counts, and performance trends to ensure optimal utilisation. This data supports timely refurbishment or replacement, avoiding unexpected failures. A disciplined approach to die maintenance protects both production efficiency and product quality.

Integrating Metal Die into Modern Production Lines

Integration is key. Metal Dies must align with automated handling, inspection, and packaging systems to streamline production. Misalignment or delays in one stage can disrupt the entire line. Therefore, dies should be compatible with modern production technologies.

Additionally, simulation and CAD modelling now help predict die behaviour under real-world conditions. This reduces trial-and-error in tooling development and shortens lead times. When well-integrated, dies act as an enabler, not a bottleneck, in production scalability.

Why Metal Dies Remain Indispensable

Despite the significant advances in additive manufacturing and flexible electronics, metal dies remain at the heart of high-volume electronics production. Their speed, precision, and repeatability are irreplaceable. If designed and maintained correctly, they can generate significant value in high-volume electronic component manufacturing.