Precision die stamping transforms flat sheet metal into highly accurate, repeatable parts for a wide range of industries. It supports automotive, electronics, appliances, and industrial equipment manufacturing. The process is systematic and involves several critical stages. Each stage must be carefully controlled to reduce variation, maintain tolerances, and cut overall production costs. Understanding these steps helps both engineers and procurement teams evaluate suppliers, improve sourcing decisions, and achieve consistent results.

Material selection and raw stock preparation

The process always begins with the right choice of material. Engineers select metals such as stainless steel, copper, aluminum, or high-strength steel depending on the application. They also consider thickness, temper, conductivity, and corrosion resistance. After this, the supplier delivers coils or sheets to the stamping plant. Technicians then inspect for surface defects, scratches, and mill scale. In addition, they verify chemical composition and mechanical properties against specifications. Finally, they record traceability data for each lot to ensure consistent quality throughout the stamping process.

Die design and engineering

The die is the foundation of precision stamping, and design plays a critical role. Engineers start by analyzing part drawings and tolerance requirements. Then, they create CAD models and strip layouts. Simulation tools help predict forming challenges such as wrinkling, springback, or cracking. Designers also evaluate clearance, pilot holes, and strip progression to maximize efficiency. Moreover, they choose between progressive, compound, or transfer dies based on part geometry. A strong design reduces scrap, improves repeatability, and lowers maintenance costs over the life of the die.

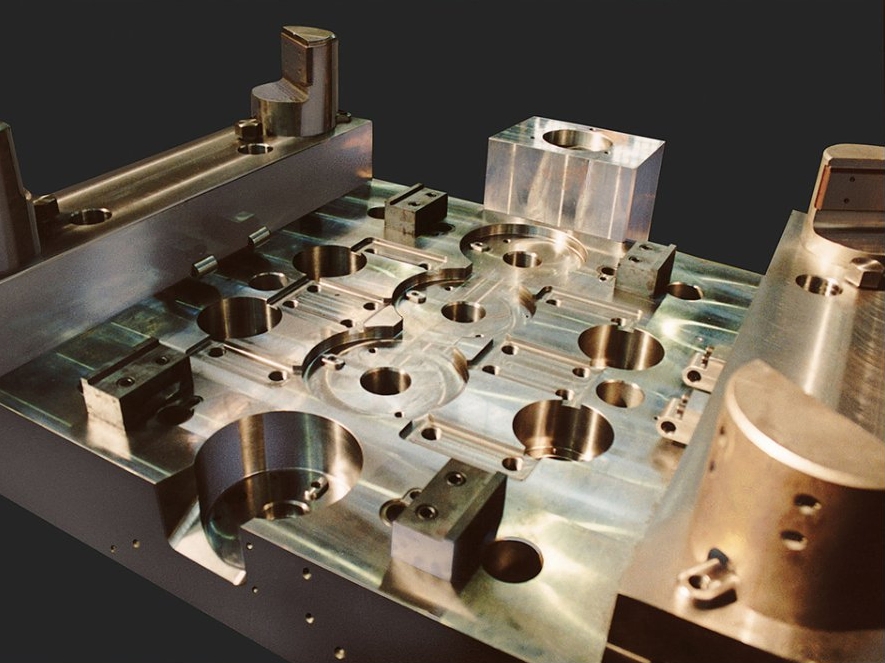

Die fabrication and toolmaking

Once the design is approved, toolmakers begin fabrication. They use CNC machining, grinding, and EDM to cut precise cavities. High-grade tool steel is selected for its hardness and wear resistance. Heat treatment improves durability and ensures the die can withstand thousands of cycles without deformation. Toolmakers also add guide pins, bushings, and springs to maintain alignment. Skilled polishing creates smooth surfaces that protect material flow. Before final assembly, technicians inspect every die component to ensure accuracy. This step is labor-intensive but guarantees long-term stability in production.

Press setup and die tryout

The next stage is preparing the stamping press for production. Technicians mount the die, align it carefully, and set proper clearances. They also calibrate feed systems, ram stroke, and press tonnage. Initial trial runs help verify accuracy. Operators check part dimensions, hole quality, and surface finish. If results fall outside tolerances, engineers adjust die components or press settings. Tryouts prevent costly defects later in full production. Once approved, the die is locked into a schedule, and the press is ready for continuous operation.

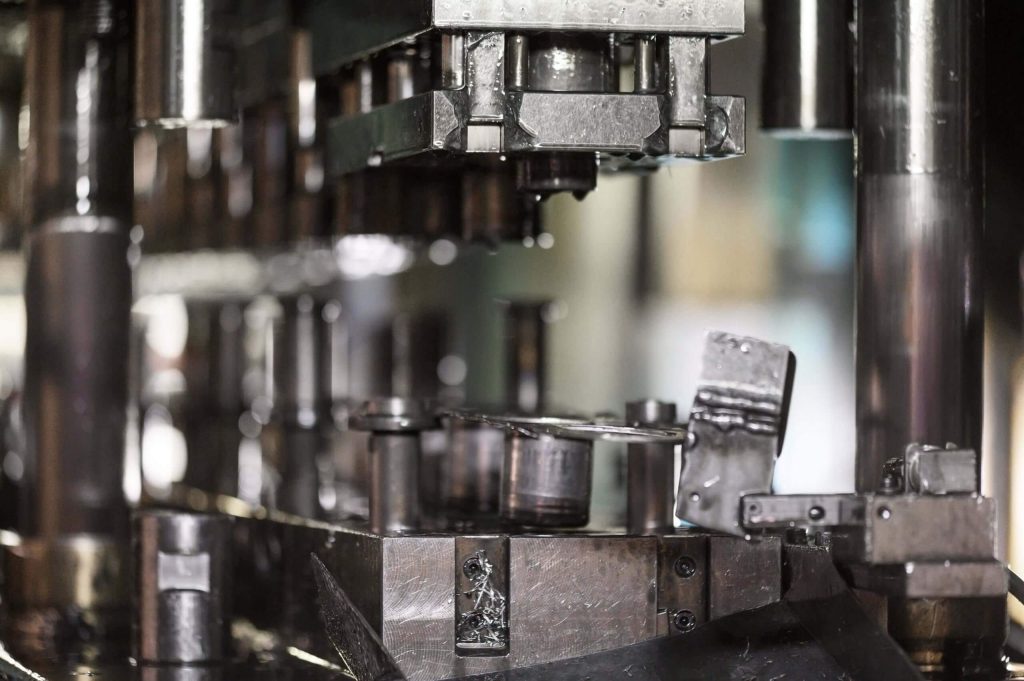

Production stamping and forming operations

During production, metal coils are fed into the press at controlled speeds. Progressive dies may complete blanking, piercing, bending, and forming in one cycle. This increases efficiency and lowers handling costs. Operators continuously monitor scrap rate and cycle consistency. Inspectors sample parts at regular intervals to confirm tolerances. Preventive maintenance schedules ensure that tool wear does not affect quality. Automated presses can run thousands of strokes per hour, producing large quantities of accurate parts. Stable production is the most cost-effective outcome of precision stamping.

Secondary operations and finishing

Many stamped parts require secondary processing before they are ready for use. Deburring removes sharp edges created during cutting. Additional steps such as coining, trimming, or tapping may be needed to refine features. Surface treatments such as plating, coating, or passivation improve corrosion resistance and appearance. Automated washing removes oils and debris before packaging. Some parts also undergo welding or sub-assembly for integration into larger systems. By completing these operations, manufacturers improve performance, extend lifespan, and meet exact customer requirements more effectively.

Inspection, testing, and quality control

Inspection ensures stamped parts match the design intent. Teams use calipers, micrometers, and gauges for standard checks. For complex components, coordinate measuring machines verify critical dimensions. Statistical process control helps track key variables across shifts. Functional tests, such as insertion or electrical checks, confirm performance. Inspectors document results and enforce traceability. When defects appear, corrective actions are applied immediately. This disciplined approach prevents failures from reaching customers. Consistent inspection builds trust, reduces returns, and strengthens supplier relationships in competitive markets.

Steps and Process of Precision Die Stamping

Each stage builds on the one before it, creating a complete workflow. First, material choice sets the foundation for quality. Next, precise design ensures efficiency and durability. Fabrication delivers accurate dies capable of long service life. Press setup and tryout eliminate early issues. Production stamping creates volume with speed and precision. Secondary finishing adds value, while inspection ensures only approved parts leave the factory.