Metal part production often relies on two dominant forming technologies: stamping and injection molding. Both processes shape raw materials into functional components used in automotive, aerospace, electronics, and consumer products. Each method has strengths, limitations, and ideal application scenarios. Understanding the differences between stamping die processes and injection molding helps engineers, buyers, and production planners choose the right approach for their projects.

Fundamental Process Differences

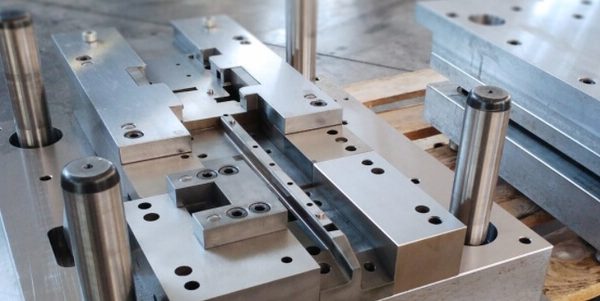

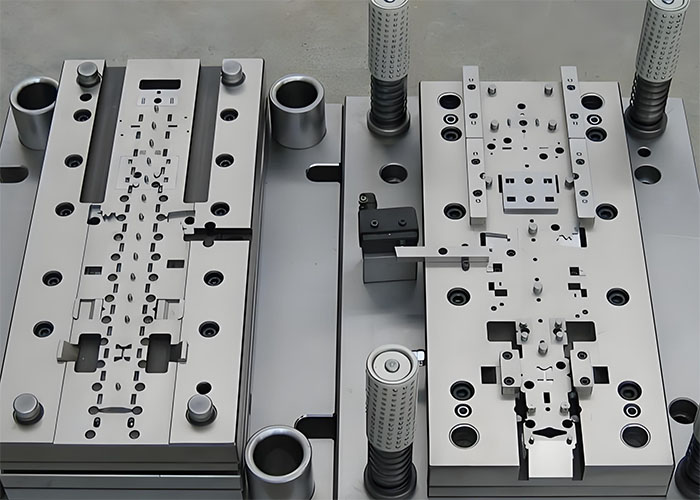

At its core, stamping uses a press and a Stamping Dies to cut, bend, or form sheet metal. The material starts as a flat coil or blank. It moves into a die that applies mechanical force and produces the final geometry in one or multiple strokes.

Injection molding, by contrast, begins with thermoplastic or metal powder fed into a heated barrel. Material melts or sinters, then is forced into a mold cavity. After cooling, the solid part ejects from the mold. Stamping primarily works with metals. Injection molding handles plastics and some metal injection molding (MIM) powders. These fundamental differences influence design, cost, and production dynamics.

Design and Geometry Considerations

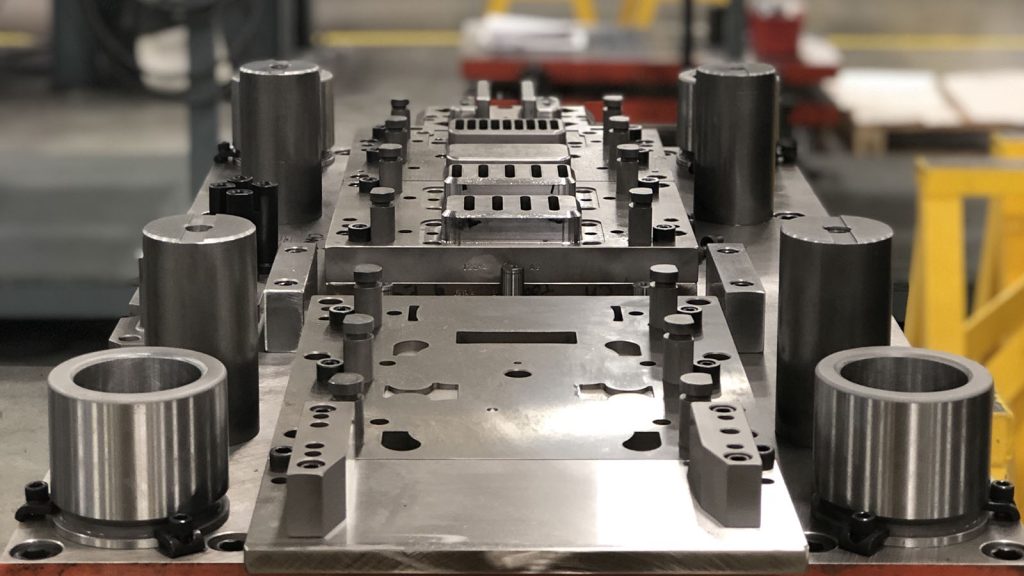

Stamping tools excel at producing parts with uniform wall thickness and features like flanges, ribs, and cutouts. These shapes form through mechanical deformation rather than material flow. Stamping dies can also include progressive die stations for multi-step forming, reducing handling time. However, extremely deep or complex 3D shapes are more challenging to stamp and may require additional operations, such as secondary bending or trimming.

In contrast, injection molding produces complex 3D geometries with undercuts, internal cavities, and intricate surface details. Designers often leverage draft angles and part consolidation to reduce assembly steps. While injection molds can handle complex shapes, they require careful design for wall thickness, cooling channels, and gate placement to avoid defects.

Material Behavior and Selection

Stamping processes typically use ductile metals such as steel, aluminum, copper, and brass. These materials deform under pressure without cracking. The selection depends on yield strength, elongation, and surface finish requirements. The stiffness and work-hardening behavior of metals directly influence die design and press tonnage.

Injection molding uses polymers such as ABS, nylon, and polycarbonate. In metal injection molding (MIM), fine metal powders are mixed with polymers and later sintered to the final density. This method allows the use of stainless steel, tool steel, or other alloys in small and complex parts. Yet, MIM adds cost and complexity compared to standard plastic molding.

Tooling Cost and Lead Time

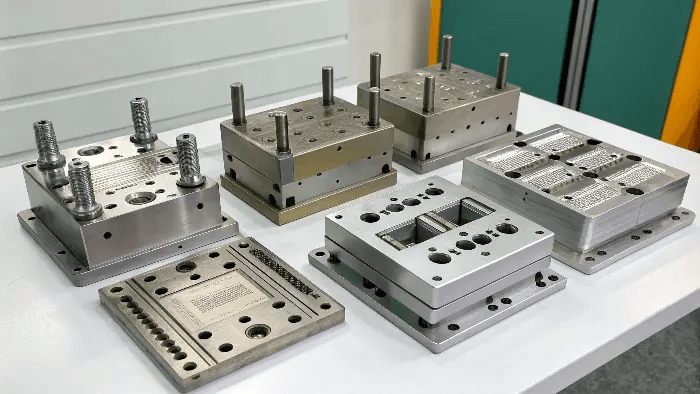

The tooling cost is a significant difference between these two methods. Stamping dies often require substantial upfront investment, especially for progressive die systems with multiple stations. A high-quality stamping tool can cost tens of thousands to hundreds of thousands of dollars, depending on complexity. However, the unit cost drops dramatically once production begins. Lead time for a stamping die ranges from a few weeks to months, depending on design and validation cycles.

Injection molds also demand upfront investment. Mold cavities, cores, and cooling systems must match material and geometry precisely. For simple plastic parts, mold costs may be comparable to those for stamping dies. For complex metal injection molds or multi-cavity plastic molds, the cost escalates further. Lead times for molds typically fall within a similar range but depend on the number of cavities and the complexity of the cooling channels.

Production Speed and Cost Per Part

After tooling is complete, stamping delivers exceptionally high production rates. Modern stamping lines can cycle hundreds to thousands of strokes per minute. High-volume automotive panels, chassis components, and precision connectors rely on these high speeds to meet demand. The cost per part decreases rapidly as volumes grow, making stamping ideal for large runs.

Injection molding also achieves high throughput, especially in plastics. Multi-cavity molds and automated handling systems further boost cycle efficiency. MIM production cycles tend to be slower due to the cooling and sintering stages. Still, injection molding remains cost-effective for moderate to high volumes of complex shapes, particularly in consumer electronics and appliance markets.

Quality and Tolerance Control

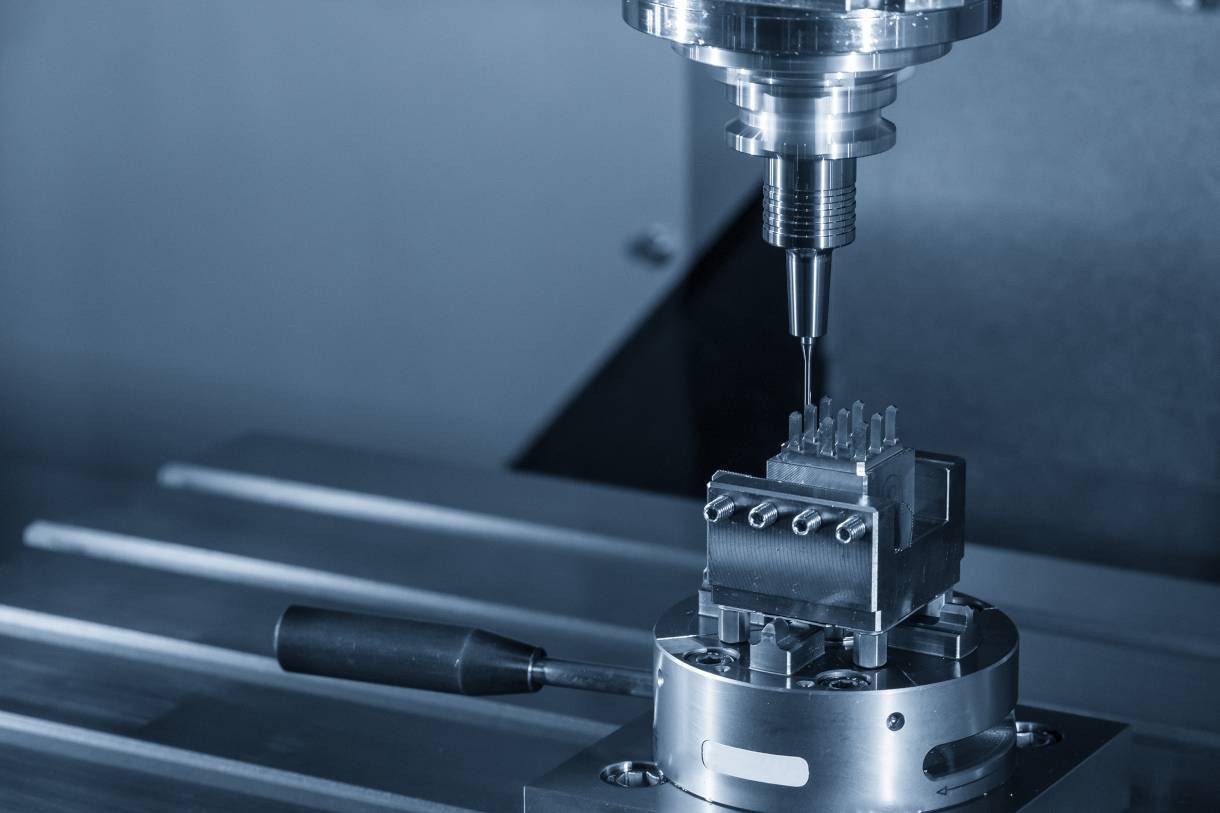

Both processes can achieve tight tolerances, but the methods differ. Stamping controls tolerances through die design, press capacity, and material handling systems. Accurate Stamping Die machining, die alignment, and consistent feed control play a significant role. For flatness, hole location, and concentric features, stamping can meet strict requirements when properly designed and maintained.

Injection molding achieves dimensional control through mold precision, thermal management, and material behavior. Variations in cooling can cause shrinkage or warping, so mold design must account for these factors. Plastic parts often include design features that offset expected shrink rates. In MIM, sintering shrinkage requires consistent part placement and uniform density to maintain tolerances.

Application Scenarios and Industry Use

Stamping excels at producing sheet-metal parts. Automotive body panels, brackets, chassis components, and electrical shields are typical examples. Progressive dies support multiple forming steps on a single press line, reducing part handling and improving consistency. When flat stock needs bending, trimming, and piercing in one sequence, stamping shines.

Injection molding dominates the production of plastic components, housings, clips, and ergonomic parts. In medical and consumer products, injection molding delivers complex 3D shapes with aesthetic appeal. Metal injection molding extends these capabilities to small, intricate metallic components where traditional machining would be inefficient or impossible.

Choosing Stamping Die for Metal Part Projects

Choosing between a Stamping Die process and injection molding depends on part design, material choice, volume, and cost targets. Stamping offers high-speed production and low unit cost for metal parts once tooling is complete. Injection molding supports detailed 3D geometry and complex features often required in plastics and MIM. Understanding these core differences helps engineers select optimal manufacturing strategies. By aligning design intent with process capability, companies achieve better quality, faster delivery, and lower total cost over the product lifecycle.