Tooling and Jigs

- Home

- Service

- Tooling and Jigs

Our Service

Service List

- Design & Engineering

- Precision Dies

- Die Assembly & Die Tryout

- Precision Parts

- Tooling&Jigs

Need For Some Help ?

For More Details Contact Us!

Phone

+86 0769-82759388-825 +86 0769-81502216-826

info@cymjkj.com

Tooling and Jigs

At Chaoyang, we provide custom tooling, jigs, and advanced fixture solutions designed to enhance efficiency, precision, and consistency across manufacturing operations. From assembly and testing to inspection and packaging, our solutions are engineered to support diverse production needs and optimize workflow performance.

Tooling and Jigs Services

Custom Tooling & Fixtures: Tailored solutions for assembly, testing, inspection, and packaging.

Precision Jigs & Fixtures: Highly accurate tools to enhance process stability and repeatability.

Rapid Prototyping to Full Production: Fast-turnaround solutions for both prototype development and large-scale manufacturing.

Tooling and Jigs Services Key Benefits

Enhanced Efficiency: Accelerate production while minimizing waste and errors.

Exceptional Precision: Maintain high accuracy across all operations.

Complete Customization: Solutions engineered for your unique production challenges.

Seamless Integration: Easy to adopt across various production lines.

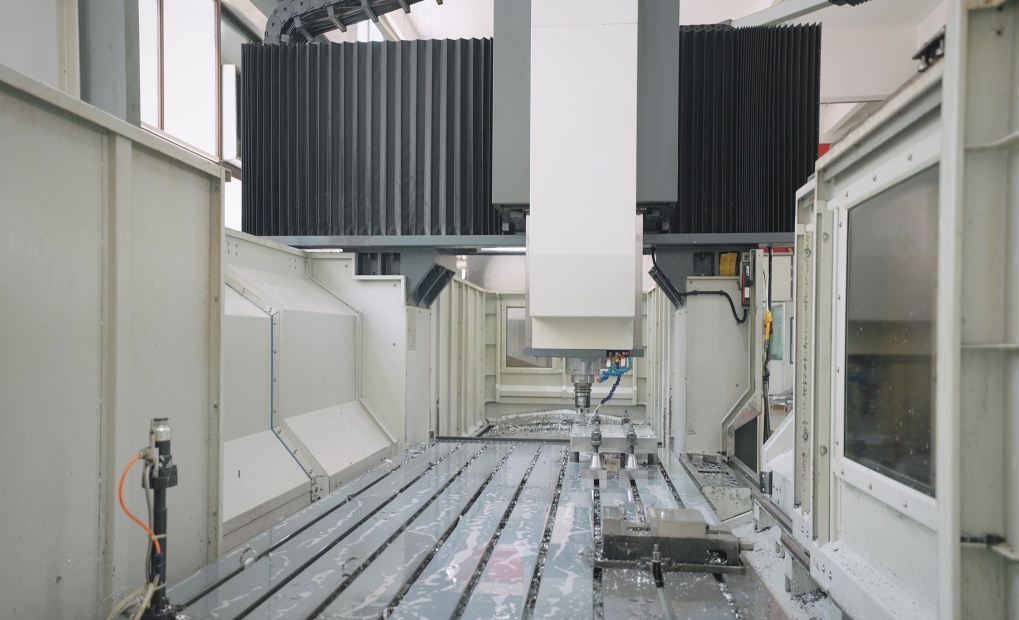

Cutting-Edge CNC Machining

Our advanced CNC machining capabilities allow us to provide diverse, customized tooling solutions for your manufacturing needs. Using the latest CNC technology, we are able to create intricate and high-precision tools and fixtures that fit the specific requirements of each client. This technology enables us to produce highly complex designs with exceptional accuracy and consistency, ensuring that your parts are manufactured to exact specifications.

Whether you’re looking for simple jigs for assembly or intricate fixtures for precise machining, Chaoyang is equipped to handle it all. Our team works closely with you to understand your needs and deliver tailored solutions that improve efficiency and reduce the risk of error in your manufacturing processes.

| Capability | Tolerance | Material | Application | Notes |

|---|---|---|---|---|

| CNC Milling | ±0.001mm | Steel, Carbide, Ceramic | Stamping Dies, Precision Machining Parts | High-precision parts, complex geometries |

| Wire EDM | ±0.002mm | Tool Steel, Carbide | Progressive Dies, Complex Stamping Dies | Ideal for intricate contours and fine features |

| Jig & Fixture Fabrication | ±0.01mm | Steel, Aluminum | Assembly, Testing, Inspection, Packaging | Ensures repeatability and process stability |

| Surface Grinding | ±0.002mm | Tool Steel, Die Components | Precision Stamping Die Components | Flatness and surface finish control |

| Die Components Fabrication | ±0.003mm | Carbide, Ceramic, Powder Metals | Stamping Dies, Precision Die Cutting | Durable components for high-volume production |

| Rapid Prototyping | ±0.01mm | Various | Prototype Stamping Dies, Fixtures | Fast turnaround for testing and design validation |

Application Scenarios

Our Tooling and Jigs Solutions Are Ideal For:

Automotive component assembly lines

Electronic device testing and quality control

Aerospace precision parts inspection

Packaging automation systems

Why Choose Chaoyang for Your Tooling and Fixture Needs?

Customization: We design and fabricate tooling and jigs tailored to your production needs.

Precision: Using advanced CNC machining technology, we ensure that every tool and jig meets the highest standards of accuracy.

Efficiency: Our expertly crafted tools optimize manufacturing operations, reducing lead times and increasing production efficiency.

Versatility: From simple jigs to complex tooling systems, we provide a range of solutions tailored to various manufacturing processes.

Reliability: Our commitment to quality ensures that every tooling and jig solution we provide is durable, reliable, and built to perform.

At Chaoyang, we provide the tooling and jigs that empower your manufacturing operations, driving consistency, quality, and performance at every step of production. Let us help you streamline your processes and achieve optimal results with our expertly engineered solutions.

Yes. We specialize in designing and manufacturing fully customized tooling, jigs, and fixtures for assembly, testing, inspection, and packaging. Each solution is tailored to your production process and integrates seamlessly into existing workflows.

We use advanced CNC machining, precision grinding, and high-quality materials to ensure every tool and jig meets strict tolerances and long-term durability. Rigorous quality control and inspection procedures confirm consistent performance across production runs.

Our offerings include assembly jigs, inspection fixtures, testing tools, packaging aids, and complex custom tooling systems. We can handle both simple designs and intricate, high-precision fixtures.

We serve automotive, electronics, aerospace, consumer goods, and industrial manufacturing sectors—essentially any industry that requires precise, reliable, and efficient production tooling.

Yes. We provide rapid prototyping for early-stage validation as well as scalable solutions for high-volume production, ensuring optimal performance throughout the product lifecycle.

Make An Appointment

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN

| Capability | Tolerance | Material | Application | Notes |

|---|---|---|---|---|

| CNC Milling | ±0.001mm | Steel, Carbide, Ceramic | Stamping Dies, Precision Machining Parts | High-precision parts, complex geometries |

| Wire EDM | ±0.002mm | Tool Steel, Carbide | Progressive Dies, Complex Stamping Dies | Ideal for intricate contours and fine features |

| Jig & Fixture Fabrication | ±0.01mm | Steel, Aluminum | Assembly, Testing, Inspection, Packaging | Ensures repeatability and process stability |

| Surface Grinding | ±0.002mm | Tool Steel, Die Components | Precision Stamping Die Components | Flatness and surface finish control |

| Die Components Fabrication | ±0.003mm | Carbide, Ceramic, Powder Metals | Stamping Dies, Precision Die Cutting | Durable components for high-volume production |

| Rapid Prototyping | ±0.01mm | Various | Prototype Stamping Dies, Fixtures | Fast turnaround for testing and design validation |