Progressive Stamping Dies

- Home

- Service

- Progressive Stamping Dies

Our Service

Service List

- Design & Engineering

- Precision Dies

- Die Assembly & Die Tryout

- Precision Parts

- Tooling&Jigs

Need For Some Help ?

For More Details Contact Us!

Phone

+86 0769-82759388-825 +86 0769-81502216-826

info@cymjkj.com

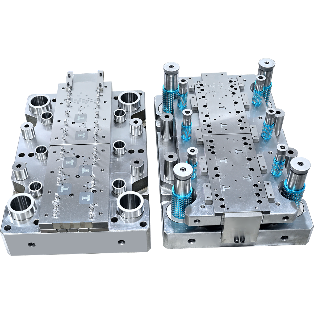

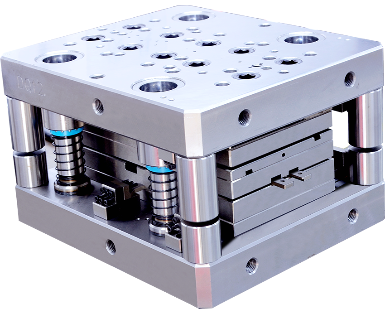

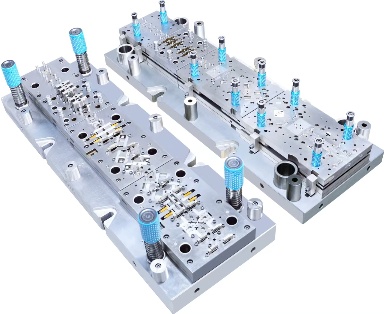

Precision Metal Stamping Die

Precision metal stamping dies, especially Progressive Stamping Dies, are the backbone of high-volume manufacturing. They enable the production of intricate, high-tolerance metal components essential for advanced industries. By combining cutting-edge design, premium materials, and meticulous engineering, our dies transform raw metal sheets or coils into precise parts through blanking, punching, bending, and forming. Chaoyang’s expertise ensures every component meets strict standards for dimensional accuracy, durability, and performance, supporting industries where reliability is non-negotiable.

Our Expertise

As a leading precision metal stamping dies manufacturer, we specialize in delivering tailored solutions for complex applications across diverse sectors. Our core competencies include:

Product Portfolio

Terminals & Connectors: High-speed, ultra-precision dies for electrical and data transmission systems.

LED & IC Components: Micro-stamping dies for delicate semiconductor and optoelectronic parts.

Motor & Electromechanical Parts: Durable dies for motors, relays, and miniature mechanical assemblies.

Customised Solutions: Bespoke dies engineered for unique geometries and material challenges.

Technical Capabilities

Advanced CAD/CAM and simulation tools for die design optimisation.

Precision machining with JG, PG, CNC, wire-cutting, and precision surface grinding technologies.

Rigorous quality control via CMM measurement and material testing.

Prototyping to mass production with fast turnaround and scalability.

Key Features of Our Progressive Stamping Dies

Precision Tool Design with SolidWorks

Leveraging advanced SolidWorks design, our dies ensure accurate and reliable stamping results every time.

Versatile Material Thickness Handling

Capable of processing materials from 0.1mm up to 2.0mm, accommodating a wide range of production needs.

From Simple to Complex Dies

We provide solutions from basic blank-through dies to fully customized progressive dies, adapting to any project complexity.

Durable Die Components

Components crafted from carbide, ceramic, powder metals, or conventional tool steel guarantee longevity and consistent performance.

Complete Assembly & Tryout Services

Our end-to-end die assembly and tryout ensure each die is production-ready, reducing downtime and ensuring quality output.

Why Partner With Us?

1. Decades of Proven Expertise

With years of hands-on experience in precision metal stamping, we bring unmatched industry knowledge to every project.

2. Innovation Meets Reliability

We integrate cutting-edge technologies with proven manufacturing methods to deliver stamping dies that consistently exceed performance expectations.

3. Commitment to Research & Development

Our continuous investment in advanced R&D allows us to optimize designs and create innovative solutions for complex challenges.

4 .Strict Quality Assurance

We adhere to rigorous quality control standards, ensuring every die meets the highest benchmarks for accuracy, durability, and consistency.

5.Customer-Centric Collaboration

Your success is our priority—we work closely with clients to provide fully tailored solutions that seamlessly integrate into your production processes.

6.Trusted Across High-Stakes Industries

From advanced electronics to aerospace and defense, our dies are trusted in industries where precision and reliability are non-negotiable.

FAQ

Specialized dies that produce complex metal parts through sequential operations in a single set, including punching, bending, and forming.

Electronics, automotive, aerospace, defense, and high-precision consumer goods.

Metals including steel alloys, copper, aluminum, titanium, and specialty alloys.

We support ultra-high precision with tolerances down to ±0.002 mm and material thicknesses from 0.1–2.0 mm.

Yes, from functional prototypes to high-volume mass production, we provide scalable solutions.

Make An Appointment

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN