TOOLING DIE SETS

- Home

- product

- TOOLING DIE SETS

TOOLING DIE SETS

Typical Data Sheet (General Specification)

| Component Type | Material Options | Tolerance | Hardness (HRC) |

|---|---|---|---|

| Upper & Lower Plates | Tool Steel / Mild Steel / 45# | ±0.01–0.02 mm | 30–45 HRC |

| Guide Post & Bushing | SKD11 / SKH-9 / SUJ2 | ±0.005 mm | 58–62 HRC |

| Spacer & Support Blocks | Pre-hardened Steel / Mild Steel | ±0.01 mm | 28–35 HRC |

| Clamping Plates | Tool Steel / Customized | ±0.02 mm | 30–45 HRC |

| Non-standard Bases | As per drawing | As requested | As required |

Product Description

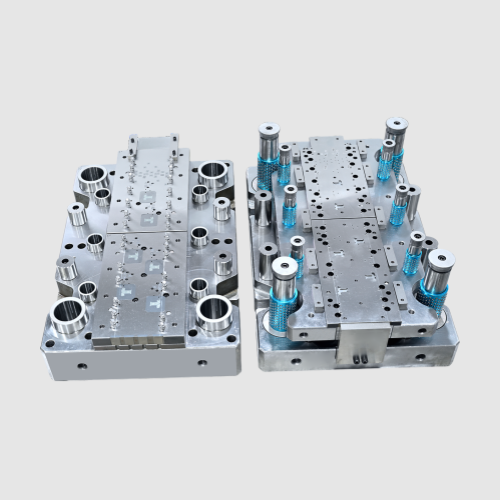

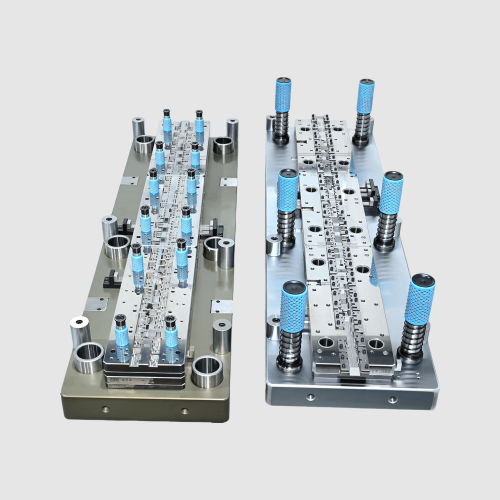

Chaoyang die sets and mould bases form the structural foundation of precision stamping, providing accuracy, stability, and long service life. We supply both standardized die bases for high-speed mass production and non-standard mould bases tailored for unique applications. Manufactured with CNC machining, precision grinding, and rigorous inspection, our products ensure consistent quality and compatibility with MISUMI, HASCO, and DME standards, serving industries such as automotive, electronics, and consumer hardware.

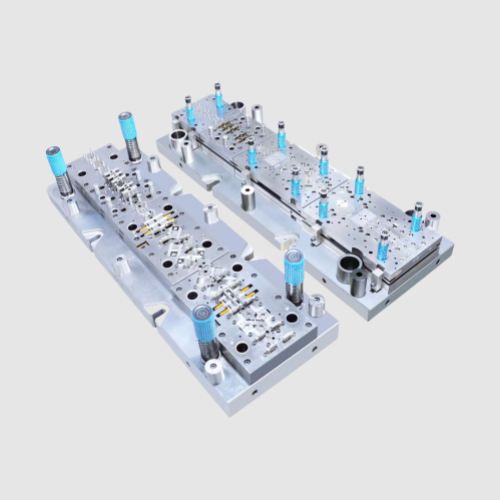

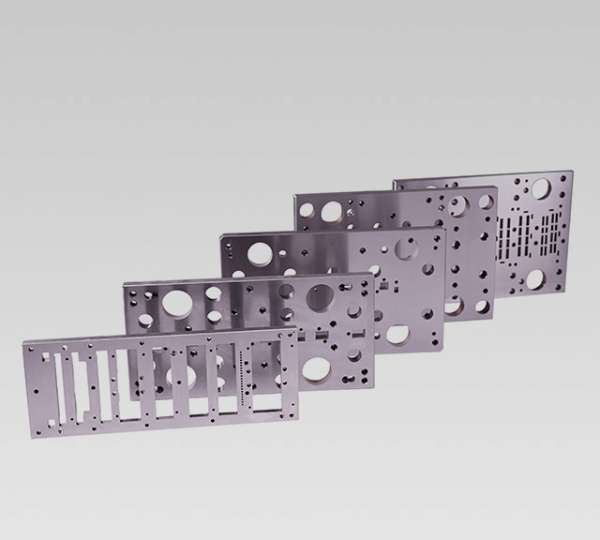

Precise Stamping Die-base

Our precise stamping die-bases are engineered for high-volume stamping and progressive die applications. With tight machining tolerances and rigid construction, they deliver excellent alignment and stability, enabling consistent part quality even in demanding mass production environments. Available in multiple sizes and material options, these die-bases are compatible with international standards such as MISUMI, HASCO, and DME, ensuring seamless integration into existing tooling systems.

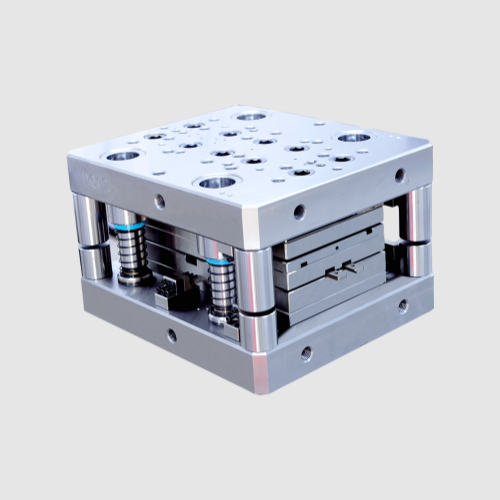

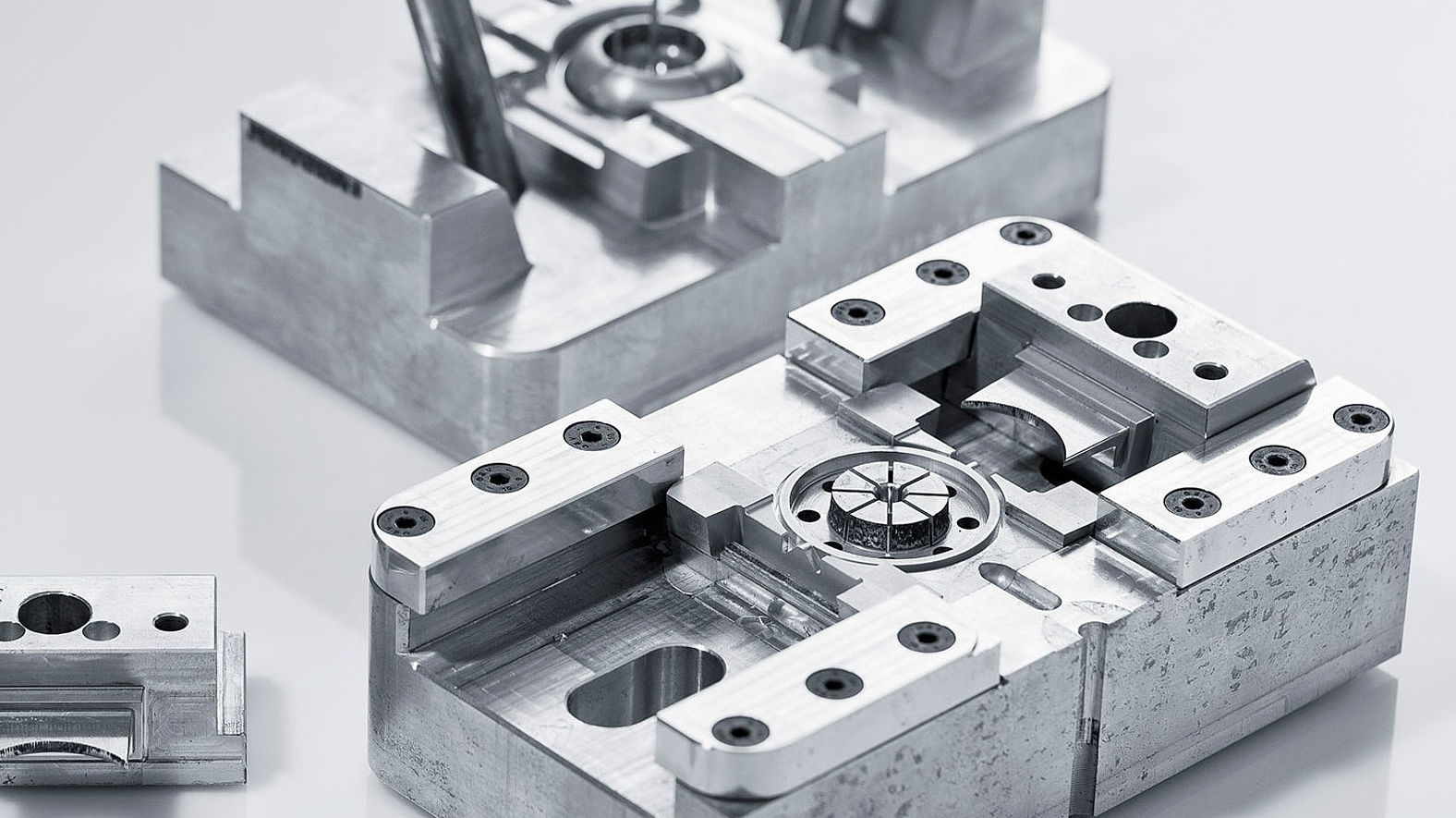

Non-standard Mould Base

For projects that require unique configurations, our non-standard mould bases offer complete design flexibility. Tailored according to customer drawings and special requirements, these bases can be produced in a wide range of materials, layouts, and dimensions. Whether for specialized equipment, prototype development, or low-volume production, our non-standard mould bases provide the adaptability needed to achieve precise and reliable performance.

Key Advantages

High Precision Manufacturing: Tolerance up to ±0.01 mm for stable performance

Flexible Options: Standard die-bases for mass production and fully customized solutions for special projects

Durable Materials: Tool steels and pre-hardened steels designed for long service life

Global Compatibility: Standardized with MISUMI, HASCO, and DME, or built to unique specifications

Industry Coverage: Widely applied in automotive, electronics, appliances, consumer hardware, and specialized industries

FAQs about tooling die sets

Precise stamping die-bases follow standardized sizes and layouts for high-volume production, while non-standard mould bases are fully customized for unique design or dimensional requirements

Yes, we provide custom mould bases tailored to your specifications, materials, and project needs.

We use high-quality tool steels, pre-hardened steels, and other industry-approved materials depending on application requirements.

Yes, our standard die-bases conform to MISUMI, HASCO, and DME specifications, ensuring seamless integration.

Automotive, electronics, home appliances, consumer hardware, and other specialized manufacturing sectors.

Need customization, please contact us

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN