PRECISION DIES

- Home

- Application

- PRECISION DIES

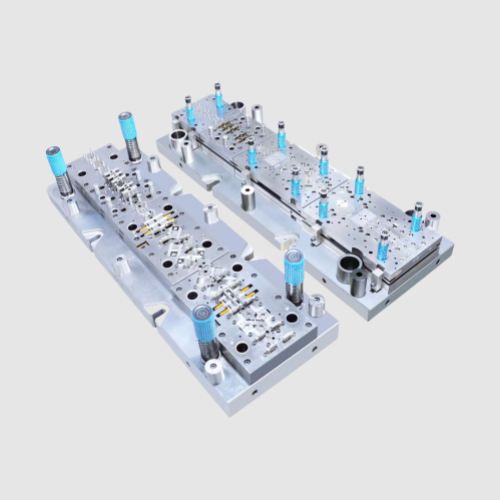

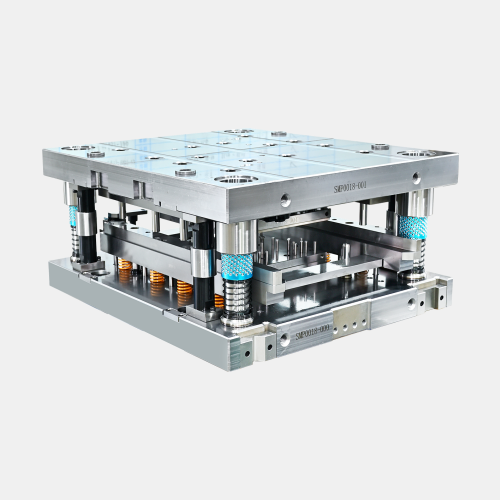

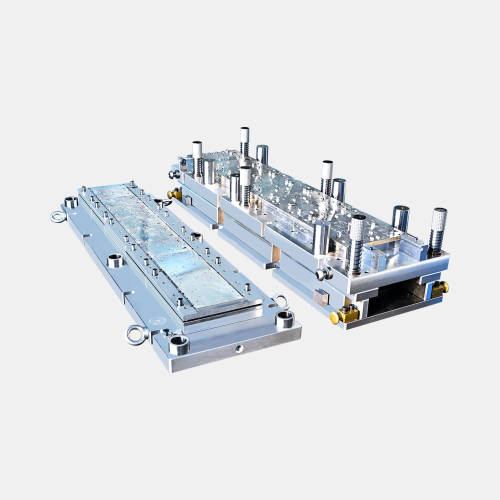

PRECISION DIES

Typical Data Sheet (General Specification)

| Parameter | Specification |

| Tolerance Range | ±0.005 mm (can reach ±0.002 mm) |

| Material Hardness | 58–62 HRC (tool steel) |

| Surface Roughness (Ra) | ≤ 0.2 μm |

| Life Cycle | Up to 10,000,000 strokes |

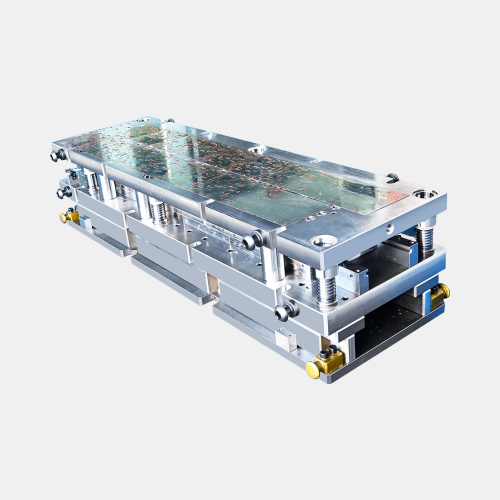

| Max Die Size Supported | 600mm*2000mm |

| Suitable Stamping Thickness | 0.05 mm – 6 mm (material dependent) |

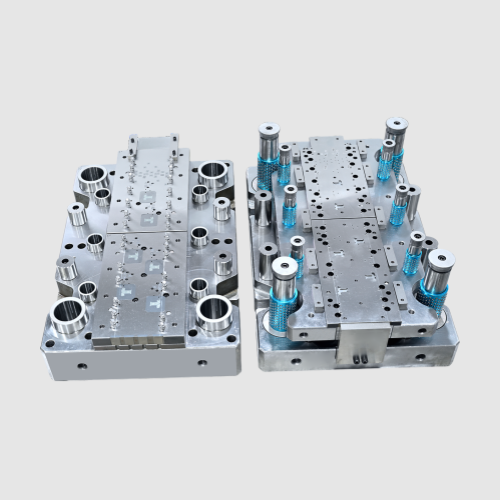

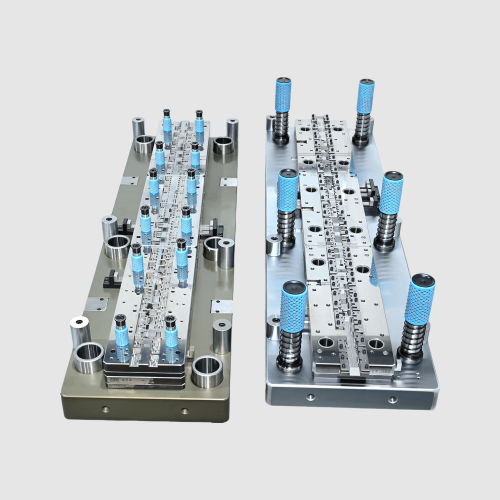

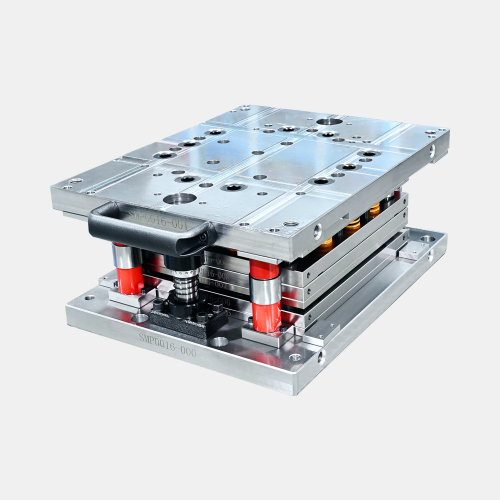

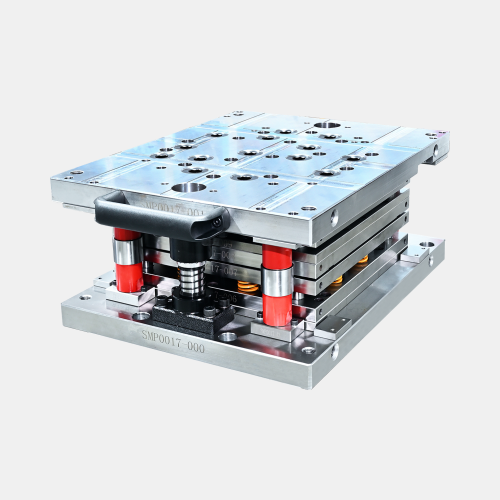

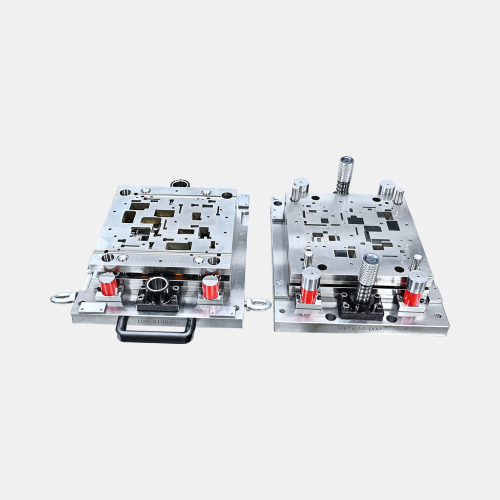

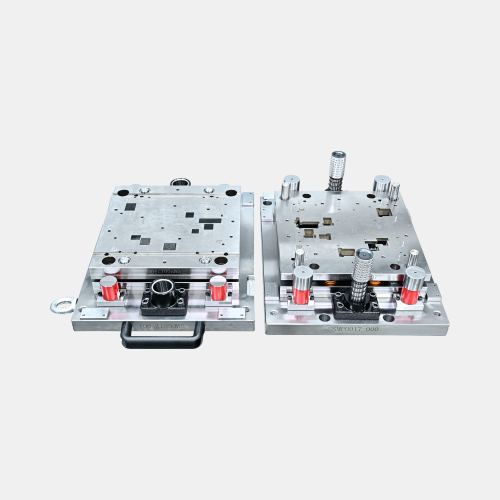

Product Description

Chaoyang precision dies are engineered for demanding applications across automotive, electronics, and industrial manufacturing sectors. Crafted from premium tool steel, our stamping dies ensure exceptional accuracy, long service life, and consistent reliability. From microelectronic components to large structural parts, our dies deliver precise forming, minimal burrs, and stable dimensions.

Advanced EDM, CNC grinding, and in-house heat treatment processes guarantee consistent performance throughout production. Beyond precision dies, Chaoyang also provides high-quality die sets and non-standard mould bases, enabling customers to integrate complete tooling solutions. For specialised requirements, our design team offers custom die kits tailored to your drawings, materials, and production needs, with professional support from the early development stage.

Key Features

Tight tolerance capability for high-precision stamping

Stable performance for long-run production

Premium tool steel and reliable heat-treatment control

Smooth forming surfaces with low burr and minimal wear

Suitable for thin-sheet stainless steel, copper, aluminum, and special alloys

Supports both prototype tooling and mass-production dies

Custom die kits based on your drawings and production needs

Why Choose Us

High repeatability:Dies maintain dimensional stability throughout long-term stamping cycles.

Strong R&D support:DFM optimization, early-stage design assistance, and fast sampling.

Advanced machining:Wire EDM down to ±0.001 mm, CNC accuracy to ±0.002 mm.

In-house quality control:CMM inspection, mold try-out, and detailed QC reports.

Durable tooling:58–62 HRC hardness and extended die life of up to 1.2 million strokes.

One-stop supply:Precision dies, die sets, and non-standard mold bases available.

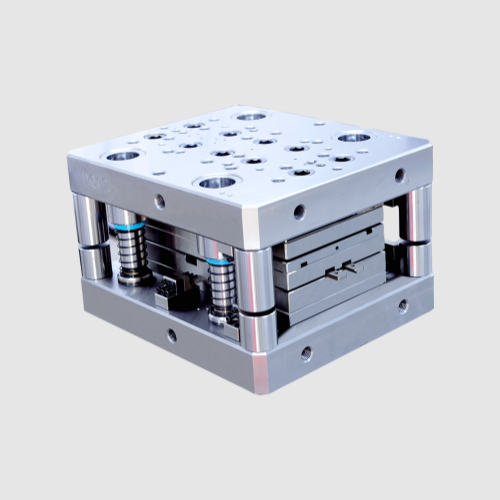

Precision Die Manufacturing Capabilities

We possess superior mold manufacturing capabilities. Combining advanced machinery, strict quality control, and decades of experience, we deliver molds that meet the most stringent industry standards. From small, complex components to large structural parts, our in-house processes ensure mold precision, stability, and efficiency.

Our technical capabilities

Jig and Coordinate Grinding: Achieves ultra-high precision on holes, slots, grooves, and contours with roundness tolerance of ±0.001 mm and machining accuracy of ±0.001 mm.

Wire EDM: Processes complex shapes and stamping die punches with wire diameters ranging from φ0.05 to 0.3 mm. Accuracy up to ±0.001 mm and surface roughness as fine as Ra0.05.

Profile Grinding: Delivers precise contours and geometries essential for high-accuracy stamping dies, with grinding accuracy of ±0.001 mm and smooth surface finishing.

CNC Machining: High-speed Japanese YASDA CNC (up to 40,000 RPM) and large-format AWEA/AGMA/Vision Wild CNC centers enable both micro-scale and large-scale die components, maintaining precision of ±0.002 mm.

Surface Grinding: Supports both large flat surfaces (up to 600 × 1200 mm) and fine micro-surfaces with Ra0.02 surface roughness and ±0.001 mm accuracy.

Advanced Equipment

Moore Coordinate Grinders for ultra-precise hole and slot finishing.

WASINO Profile Grinders for complex contour accuracy.

Sodick & Seibu Wire EDM systems for oil-based and water-based cutting.

AWEA, AGMA, Vision Wild CNC Machining Centers for large-scale and high-volume production.

YASDA High-Speed CNC (Japan) for small, intricate precision features.

Application Areas

Automotive Components

Brackets, connectors, battery terminals, automotive stamping parts

Electronics Industry

Sensor housings, microelectronic connectors, PCB shields, custom die design applications

Home Appliances

Metal housings, brackets, internal components, precision dies for appliances

Industrial Manufacturing

Metal enclosures, machine parts, structural components

FAQs about Precision Dies

Yes. We provide precision stamping dies, durable die sets, and non-standard mold bases, enabling you to source all critical tooling from one supplier.

Absolutely. Our design team can create custom die kits tailored to your specifications and production needs.

Delivery depends on complexity and volume, but we prioritize efficiency while ensuring high-quality manufacturing.

Chaoyang uses advanced EDM, CNC, profile and surface grinding, and strict quality control processes to guarantee precision and consistency.

Yes, we accommodate both prototype and small-batch production without compromising accuracy or quality.

Need customization, please contact us

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN