Precision machining is at the heart of modern metal die manufacturing. Complex projects cannot rely on general machining tools alone. They demand high-accuracy equipment, strict process control, and a skilled team. Every micron matters when building dies for automotive, aerospace, and electronics. Precision machining ensures that even the most complex die projects achieve consistency, durability, and performance.

The Role of Precision Machining in Modern Metal Die Manufacturing

Precision machining differs from conventional machining through its ability to achieve ultra-tight tolerances. While traditional methods may allow slight deviations, die production cannot risk inaccuracies. Automotive stamping dies or aerospace die components require consistent precision across thousands of parts. In Europe and North America, customers expect strict compliance with ISO standards. This drives the industry to invest in advanced CNC machining for dies and robust quality assurance systems.

Challenges in Complex Metal Die Projects

Complex die projects often involve multi-step processes and intricate geometries. The challenges include maintaining wear resistance and minimizing tolerance buildup. Even small errors can accumulate, leading to production failures. Customers frequently raise concerns about efficiency, cost, and tool life. For example, in high-volume automotive stamping, downtime caused by inaccurate dies translates directly into financial loss. Accurate machining reduces these risks and builds customer confidence.

Advanced Precision Machining Techniques Used in Metal Dies

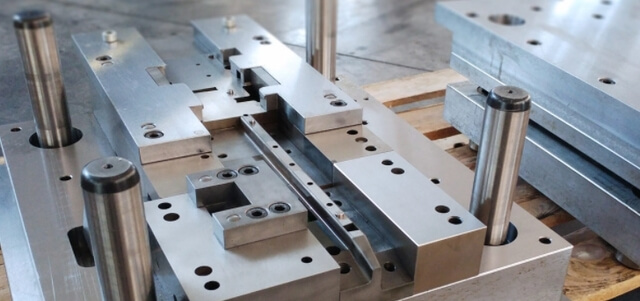

Manufacturers employ advanced methods such as CNC milling, EDM, precision grinding, and laser cutting. Five-axis machining enables the production of intricate shapes that were previously impossible. High-precision inspection equipment ensures dimensional accuracy at the micron level. These combined techniques guarantee stability throughout the die lifecycle. By leveraging precision machining services, companies meet demanding specifications without sacrificing production speed.

Custom Design Support with Precision Machining

Every complex die project begins with a tailored design process: concept, prototype, validation, and batch production. Accurate machining plays a key role in transforming digital models into physical components. This ensures that custom metal die design requirements are met without compromise. In Western markets, customers value flexibility and adaptability. Accurate machining enables manufacturers to deliver personalised solutions that align with industry-specific needs.

Enhancing Durability and Performance of Metal Dies

Durability is critical in reducing costs and improving reliability. Material selection, heat treatment, and precision machining work together to extend die life. Tool steels and alloys are hardened to resist wear. Accurate machining prevents stress points and cracks. In the automotive sector, optimized dies improve cycle speed. In electronics, well-machined dies reduce burrs and ensure flawless component shapes. Accurate machining provides the durability customers demand.

Precision Machining for Different Industry Applications

Different industries place unique demands on metal dies. In automotive manufacturing, dies must handle high-speed stamping of thin components. Aerospace industries require lightweight yet durable structures, often involving advanced alloys. Electronics rely on dies to produce small, complex parts with micro-scale accuracy. Precision machining services adapt to these varied needs, ensuring consistency and efficiency across industries.

Why Work with an Experienced, Accurate Machining Partner

Partnering with a skilled machining provider brings clear advantages. Experienced designers and advanced CNC machining equipment guarantee reliable results. Strong project management ensures timely delivery and predictable outcomes. Moreover, compliance with Western quality standards reassures customers in Europe and North America. Choosing the right partner for complex die projects reduces risk and builds long-term trust. Accurate machining is not only about technology but also about expertise.

Final Thoughts on Precision Machining Solutions Supporting Complex Metal Die Projects

Precision machining is essential for modern metal die manufacturing. It enables accuracy, durability, and customization in demanding industries. A combination of advanced techniques and expert teams ensures success. Companies seeking custom metal die design benefit from reduced costs, faster turnaround, and longer die life. For organizations aiming to stay competitive, working with a trusted partner in precision machining is the next step. Contact us today to explore how precision machining solutions can support your complex die projects.