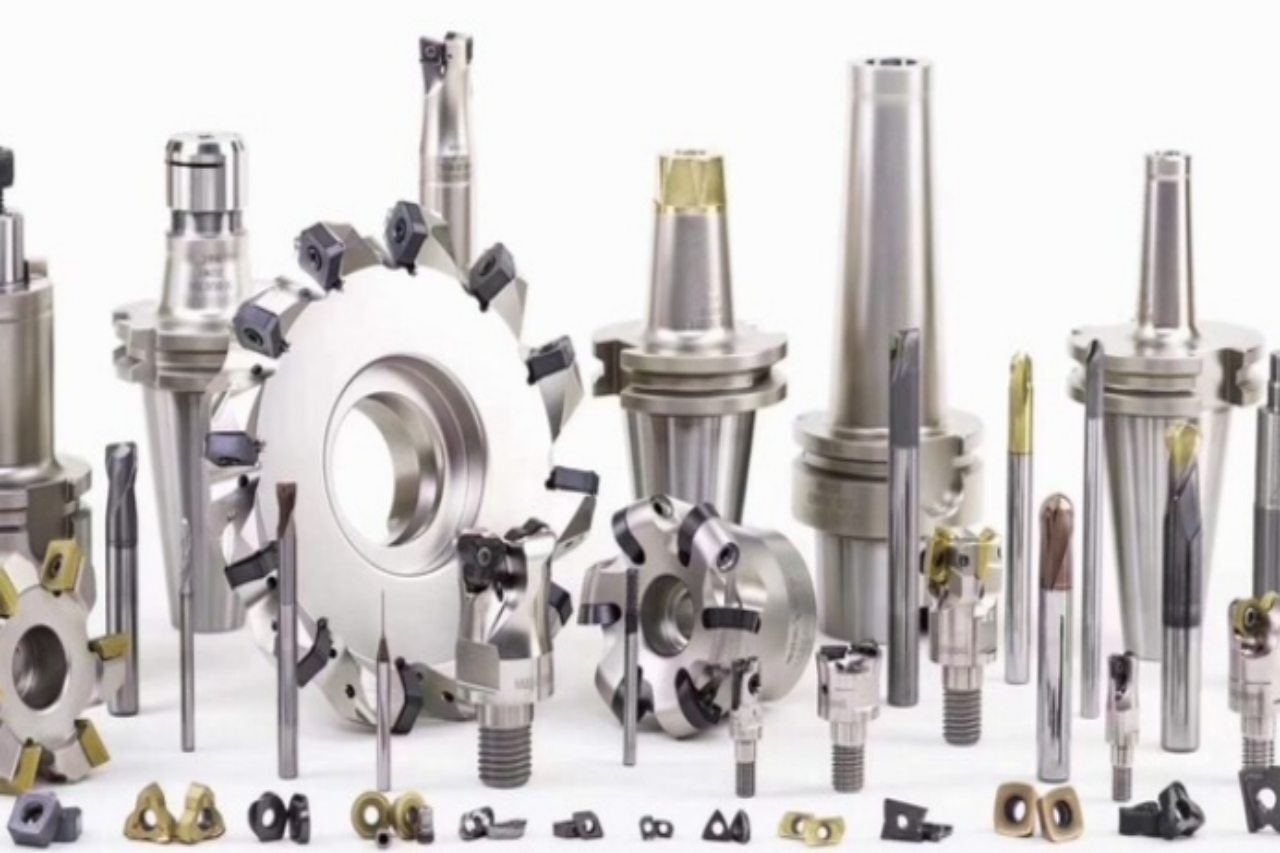

In CNC machining, tool selection directly defines part quality. Many manufacturers focus on machines and programs first. That approach misses a critical point. Cutting tools interact with material every second. They control accuracy, surface finish, and dimensional stability. Poor tool choices quickly degrade CNC-precision parts, even on high-end machines.In stamping die and tooling applications, tolerances stay tight. Machined components often guide motion, align inserts, or control clearances. Any deviation causes assembly issues. Tool selection becomes a quality decision, not a cost shortcut. Engineers who treat tooling strategically achieve more consistent results across production batches.

Cutting Tool Geometry and Its Direct Impact

Tool geometry affects how material shears and flows: rake angle, clearance angle, and edge preparation matter. Sharp tools reduce cutting forces. They also minimise heat generation. This combination helps maintain dimensional accuracy.

For CNC Precision Parts with fine features, aggressive geometry causes chatter. Chatter ruins surface finish and edge definition. Conservative geometry improves stability but slows cycle time. Skilled machinists balance both. They choose tools that match material hardness and part geometry, not just speed targets.

Micro-radius cutting edges also deserve attention. Too large causes rubbing. Too small chips quickly. Proper geometry preserves tool life while maintaining precision.

Tool Material Selection for Different Workpiece Metals

Tool material must match the workpiece. Carbide dominates modern machining for a reason. It offers hardness and thermal resistance. However, carbide grades vary widely. Fine-grain carbide suits finishing. Tougher grades handle interrupted cuts.

High-speed steel still works in specific cases. Soft metals and low-volume runs benefit from its toughness. Ceramic and CBN tools are suitable for machining hardened steel. They enable grinding-level finishes under controlled conditions.

For CNC Precision Parts used in stamping dies, tool steel components often require hardened machining. Using the wrong tool material leads to rapid wear or edge failure. That risk increases scrap and rework costs.

Coatings and Their Role in Precision Stability

Tool coatings do more than extend tool life. They influence friction, heat transfer, and chip evacuation. TiAlN coatings resist heat well. They are suited to dry machining of hardened steels. AlTiN performs better at high cutting speeds.

DLC coatings excel in aluminum machining. They prevent the build-up of edge. Clean edges improve surface consistency. This advantage matters when producing CNC Precision Parts with tight cosmetic or functional requirements.

However, coatings add thickness. In micro-machining, that thickness affects edge sharpness. Engineers must carefully consider coating benefits versus geometric impact.

Tool Wear, Monitoring, and Dimensional Drift

Tool wear directly causes dimensional drift. As edges dull, cutting forces rise—heat increases. Parts slowly grow out of tolerance. Many quality issues trace back to unmanaged tool wear.

In precision machining, proactive tool change strategies matter. Waiting for visible failure costs money. Using tool life data improves predictability. Some shops integrate spindle load monitoring. Others rely on part inspection trends.

For CNC Precision Parts used in tooling assemblies, even minor drift causes misalignment. Early tool replacement often saves more than it costs.

Tool Rigidity and Machine Compatibility

Tool rigidity influences vibration and deflection. Long overhangs amplify deflection. Thin tools bend under load. Both reduce accuracy. Selecting the shortest possible tool immediately improves stiffness. Tool holders matter too. Hydraulic and shrink-fit holders offer better concentricity. Improved runout control enhances surface finish and tool life. Standard collet systems struggle in high-precision applications. When machining CNC Precision Parts for dies, rigidity protects geometric integrity. Stable tools maintain bore roundness, flatness, and perpendicularity.

Process Optimization Through Tool Standardization

Standardising tooling simplifies process control. Using consistent tool families reduces variability. Setup times drop. Operators gain familiarity. Quality stabilises across shifts.

Some manufacturers maintain tool libraries matched to material groups. This approach improves repeatability. It also supports faster onboarding of new machinists.

For CNC Precision Parts suppliers, standardised tooling improves scalability. It allows consistent quality across machines and production cells.

Final Thoughts on CNC Precision Parts Quality

Tool selection shapes machining outcomes more than many realise. Geometry, material, coating, rigidity, and wear management all matter. Ignoring any factor introduces risk. High-quality CNC Precision Parts demand intentional tooling decisions. Precision does not come from machines alone. It comes from understanding how tools behave under real cutting conditions. Manufacturers who invest in tooling knowledge achieve better accuracy, longer tool life, and lower total cost. In precision-driven industries, that advantage compounds over time.