Every precision part begins with a well-designed tool and die set. But knowing how to use a die set correctly is what truly separates consistent quality from costly downtime. Whether you are setting up a new press or fine-tuning an existing line, understanding each step helps ensure safety, accuracy, and long tool life. In this guide, you’ll learn the practical workflow of preparation, setup, testing, and maintenance so you can keep your production efficient and reliable.

Preparation and Setup

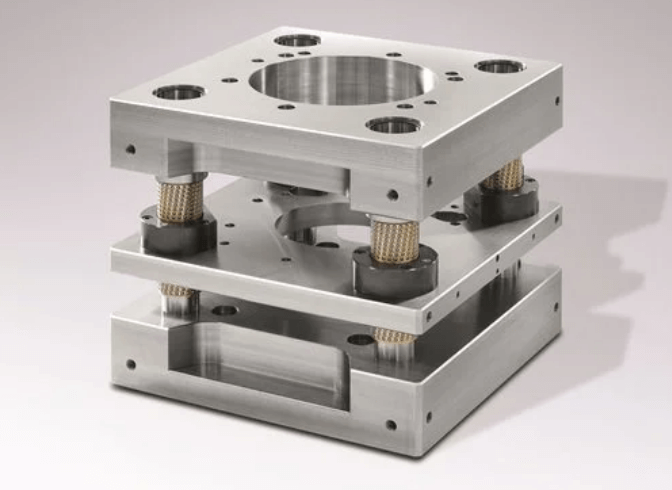

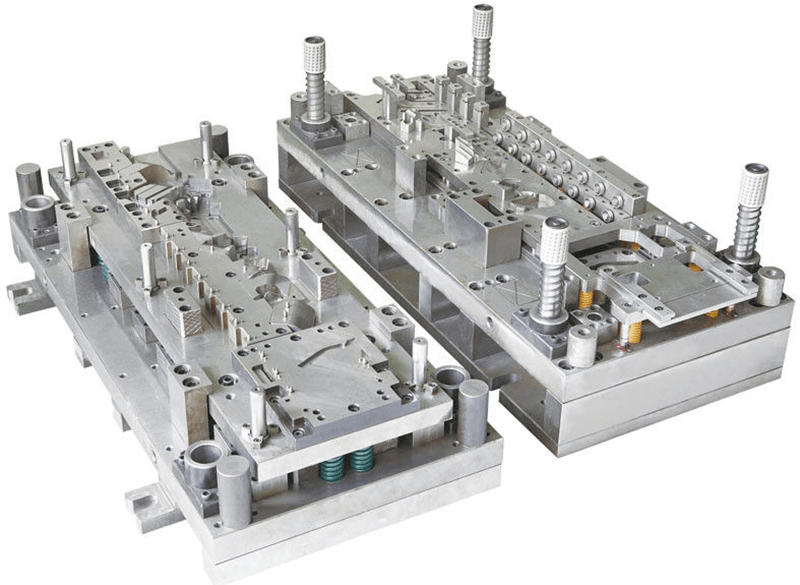

Before installing a die set into a press machine, check the press specifications and tonnage capacity. Each die sets is designed for specific materials and thicknesses, so matching the press capacity to your die prevents overloading. Securely mount the lower die on the press bed, then align the upper die using the guide pins. Proper alignment ensures uniform cutting and forming. Use feeler gauges to verify even contact between plates. Tighten the die clamps gradually and crosswise to avoid distortion. A slight misalignment at this stage can lead to costly rework or damaged tooling later.

Lubrication and Maintenance

A well-lubricated die set runs smoother and lasts longer. Apply high-quality stamping oil to reduce friction between punches and dies. Regular lubrication minimizes wear and prevents galling, which can ruin the precision finish of your components. Always follow the manufacturer’s lubrication chart—too much oil attracts debris, while too little increases heat and tool wear. Maintenance schedules should include cleaning, re-lubrication, and inspection after every production shift. Record the maintenance activities in a logbook. It’s not just good practice—it’s essential for process traceability and quality assurance.

Setting the Stroke and Shut Height

Once the die set is mounted, adjust the press stroke and shut height accurately. The shut height is the distance between the ram and press bed when the ram is at its lowest position. Incorrect shut height can lead to incomplete forming, burrs, or even die breakage. Use the setup gauge or dial indicator to fine-tune the setting. For example, in precision stamping operations for connectors or terminals, a 0.01 mm variation can affect part fit and function. Always double-check the ram position before starting production, and lock the adjustment securely.

Running a Test Piece

Never go straight to full production after setting up a die set. Always perform a test run using a sample material of the same thickness and grade. Observe the first piece for burrs, deformation, or misalignment. Measure critical dimensions using micrometers or calipers. Compare results with the drawing tolerance. If parts fall outside the acceptable range, stop immediately and readjust. In a real case from an automotive supplier, skipping this step led to a complete batch rejection—over 10,000 parts were scrapped due to a 0.05 mm height error. Testing early saves both money and headaches.

Continuous Monitoring During Operation

Once production starts, operators should monitor stroke pressure, sound, and part quality. Any unusual vibration, noise, or increase in press load could indicate die wear or misalignment. Use sensors or load monitors if available; many modern stamping lines include these for predictive maintenance. Keep an eye on scrap rate—if it rises above 2–3%, something’s off. Minor adjustments during operation help maintain consistency and prevent catastrophic tool damage. Stop immediately if a component cracks or a punch sticks; forcing the press will only make things worse.

Safe Handling and Storage

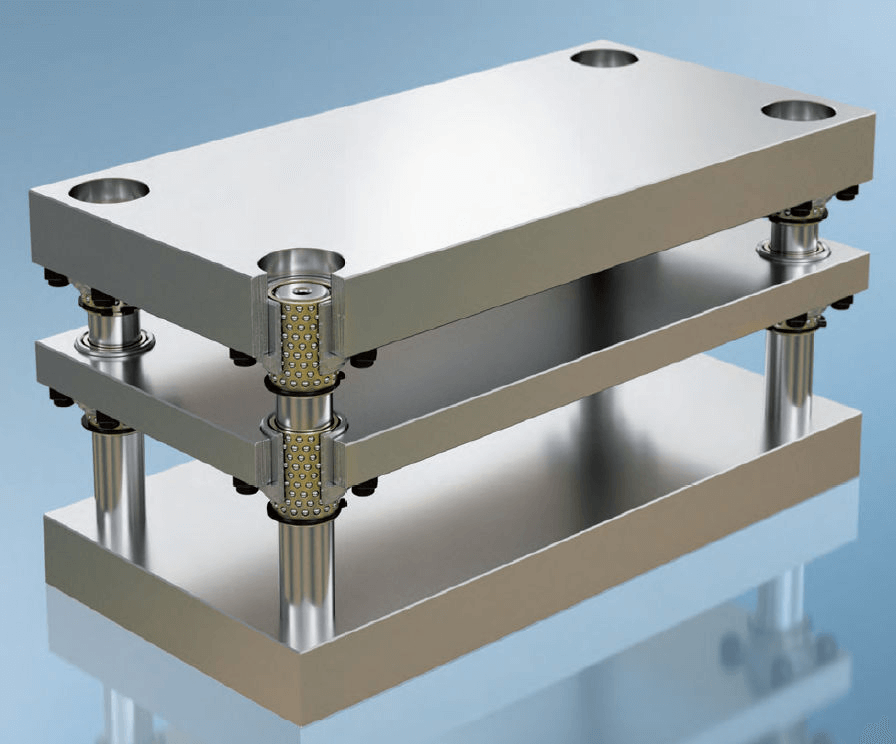

When not in use, die sets must be handled and stored correctly. Always use lifting equipment rated for the die’s weight. Avoid dragging or dropping the set, as impacts can misalign guide pins and bushings. Clean and apply rust-preventive oil before storage. Store horizontally in a dry environment with temperature control. For high-precision dies used in electronics or connector production, even humidity can cause corrosion on guide surfaces. Label each die clearly with identification numbers and usage history to streamline future setup and maintenance.

Mastering the Use of a Die Set

Using a die set effectively combines technical precision, preventive maintenance, and attention to detail. Every stage—from preparation to storage—directly affects part accuracy and tool lifespan. With consistent procedures and skilled operators, a die set can produce millions of identical components with minimal downtime. Whether you’re working in automotive, electronics, or appliance manufacturing, mastering this process defines your production quality.