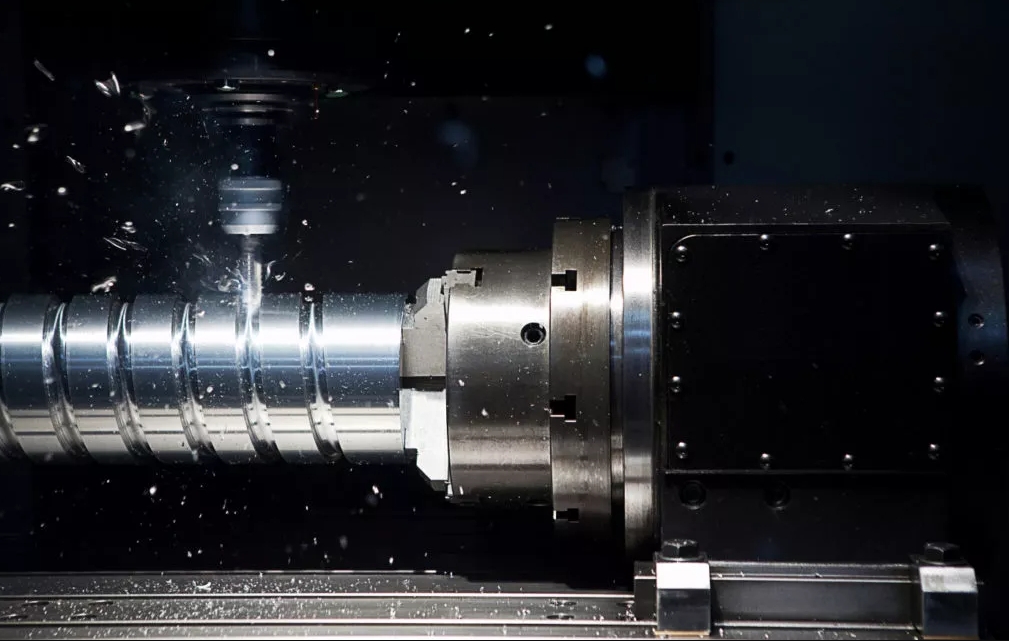

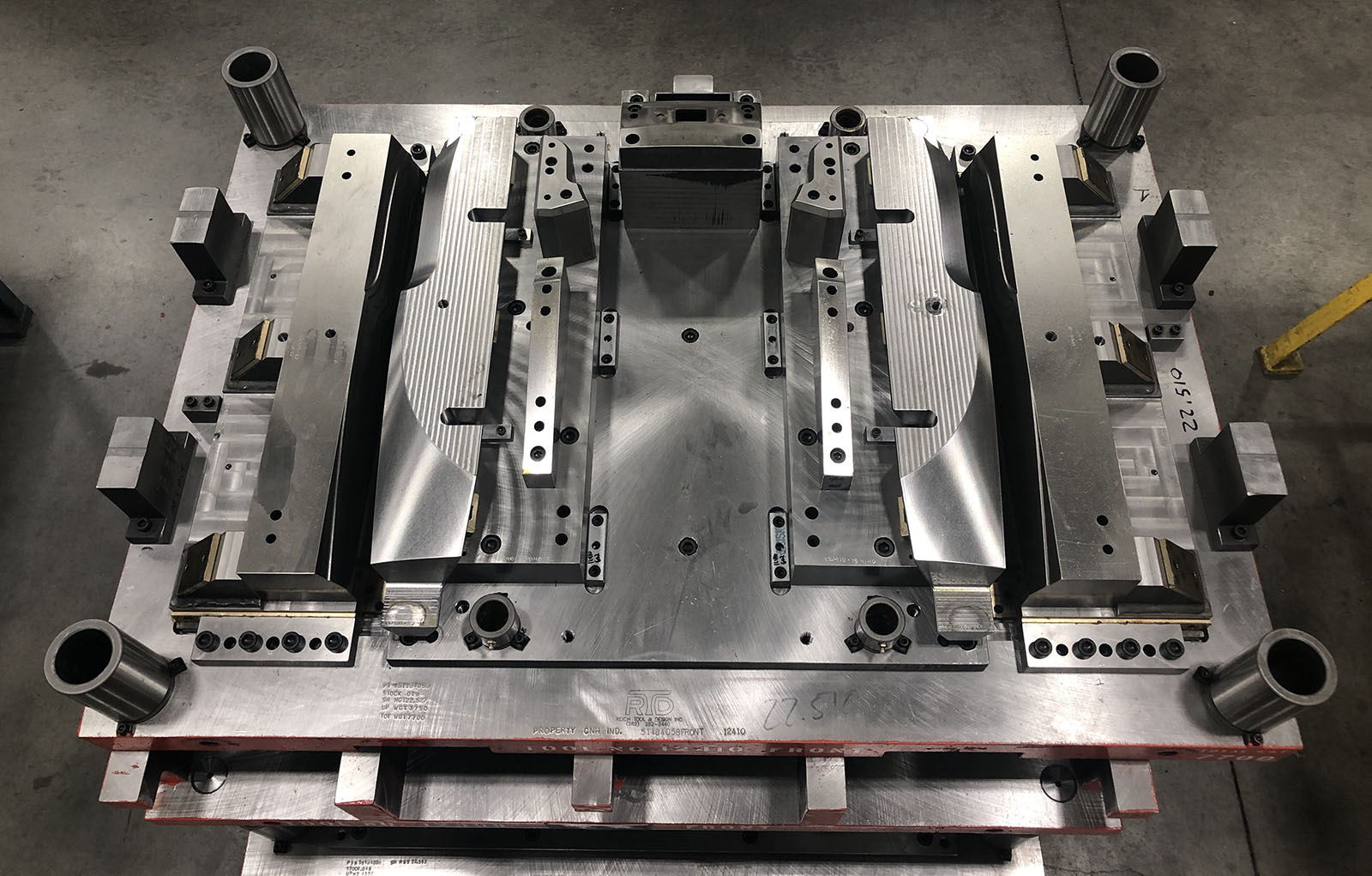

Molds are basic process equipment with large usage and wide influence in the manufacturing industry. They are known as the “mother of industry” and “crown industry” and are high-tech intensive industries. Stamping die-a special process equipment that processes materials (metal or non-metal) into parts (or semi-finished products) in cold stamping is called cold stamping die (commonly known as cold stamping die). Stamping-is a pressure processing method that uses a mold installed on a press to apply pressure to the material at room temperature to separate or plastically deform it, thereby obtaining the required parts.

Stamping dies are indispensable process equipment for stamping production and are technology-intensive products. The quality, production efficiency and production cost of stamping parts are directly related to mold design and manufacturing. The level of mold design and manufacturing technology is one of the important indicators of a country’s product manufacturing level, and largely determines the quality, efficiency and new product development capabilities of the product. At present, multi-station progressive dies with step accuracy and forming accuracy of about 2μm can be produced.

Small precision hardware continuous molds belong to high-end molds in the mold industry, with the characteristics of complex structure, high precision of parts processing, fast stamping speed and long service life. Small hardware high-speed continuous stamping molds are widely used in the electronics industry, and are also the most important tools for developing and producing structural parts of emerging products such as mobile phones and other mobile communication terminals. In the “Eleventh Five-Year Plan” of the mold industry, precision stamping molds, especially small precision hardware high-speed continuous stamping molds closely related to the electronic information industry, are listed as development priorities. To produce high-precision and high-stability stamping parts, it is necessary to improve the technical level of stamping molds. With the development of microelectronics technology, the integration of consumer terminals such as mobile phones and digital products is getting higher and higher, while their size and weight are decreasing significantly, requiring the various components inside them to be smaller and smaller. For example, the connectors supporting mobile phones and digital products are also developing towards ultra-miniaturization and thinness. The lead spacing of the connector has been reduced to 0.5mm, 0.4mm, and 0.3mm, which also promotes the development of precision mold technology.

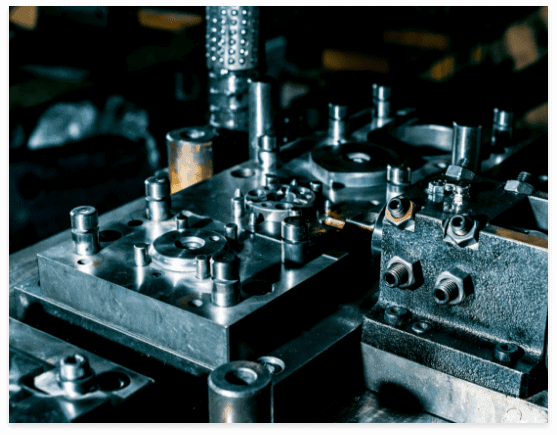

(1) Vigorously cultivate talents in mold design and processing;

(2) Vigorously improve the level of domestic mold processing equipment;

(3) Vigorously improve the quality of domestic mold materials;

(4) Support domestic enterprises with good mold foundation, and gradually produce a group of leading mold enterprises close to international standards.