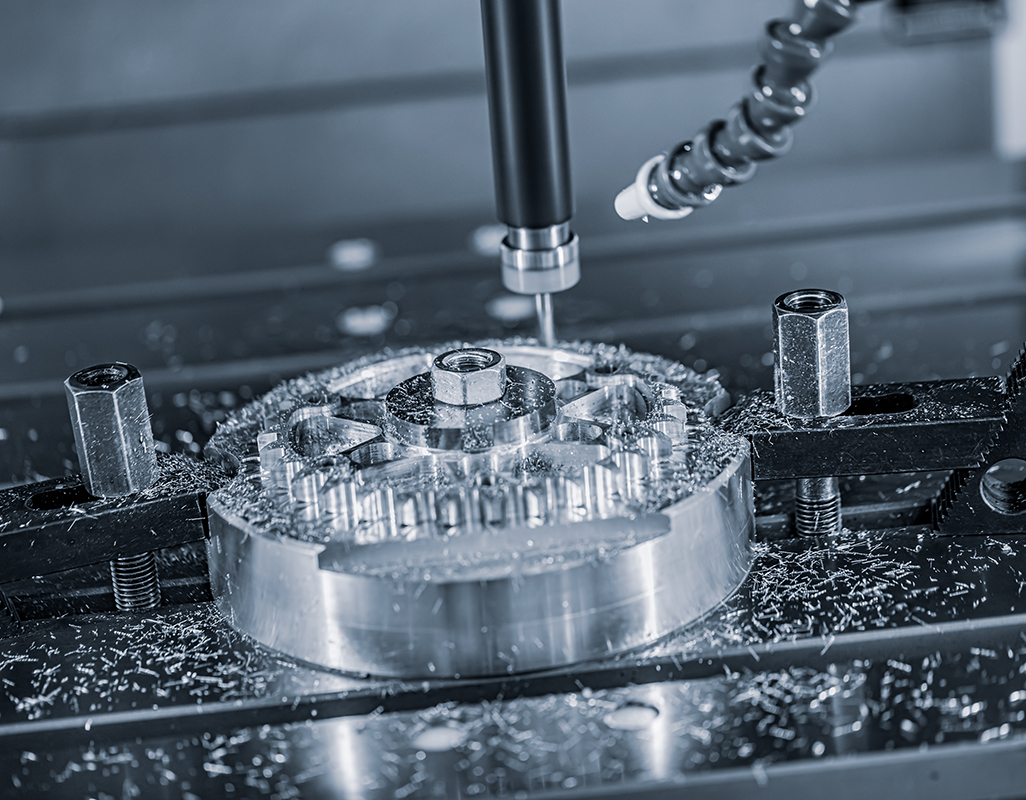

Progressive metal die technology accelerates production and lowers costs. Manufacturers use it to stamp, pierce, bend, and form parts in a single continuous operation. For high-volume runs, this approach eliminates the need for multiple setups and manual handling, thereby streamlining the process. As a result, cycle times shrink and throughput grows. Moreover, scrap falls because dies control key dimensions tightly. Additionally, progressive dies enhance consistency across long runs. This article explains how progressive metal die design, tooling, process control, automation, and maintenance increase manufacturing efficiency and output.

Fewer setups, higher throughput

Progressive metal dies press feed coil stock through multiple stations in one pass. Therefore, each stroke performs a sequence of operations. Consequently, you avoid repeated loading and unloading. As a result, takt time drops and overall throughput rises. Additionally, fewer setups result in less downtime between jobs.

Furthermore, changeovers between similar parts take minutes, not hours. For manufacturers seeking to increase volume, this directly improves machine utilisation and reduces per-part costs. Additionally, fast tooling change systems further compress lead times.

Integrated operations reduce handling errors

By combining punching, bending, and forming in a single tool, the progressive metal die reduces the number of touchpoints. Thus, fewer operators handle the part during production—consequently, incidents of human error and misalignment decline. Moreover, integrated tooling ensures that critical dimensions are maintained throughout multiple operations. Therefore, components arrive at assembly with tighter tolerances. In practice, this reduces downstream rework and assembly line pauses. Hence, quality and line efficiency both improve. Also, fewer handling steps minimise the risk of contamination and damage.

Material and yield optimisation

Progressive metal die layouts maximise nesting and yield. Designers place operations to use the web efficiently and to reduce scrap strips. Therefore, you save raw material on every coil. Additionally, progressive dies can include perforations or micro-features that support automated separation later. As a result, you reduce waste handling and cost. Moreover, when combined with just-in-time coil supply, inventory and capital are tied up in stock. Thus, overall material efficiency improves; additionally, yield gains result in a lower environmental impact and reduced handling costs.

Faster tool validation and repeatability

Validating tools in a progressive metal die environment yields long-term benefits. After the final setup, the die repeats the same sequence precisely. Therefore, you get consistent parts across shifts and operators. Additionally, instrumented runs and initial capability studies enable the establishment of baseline metrics quickly. Then SPC monitors keep control over critical dimensions. Consequently, you reduce variation and reject rates. Also, repeatability enables a confident ramp-up for new programs. Moreover, documented settings cut setup time for repeat jobs and support continuous improvement.

Automation and inline inspection

Progressive metal die presses integrate well with automation. Robotic part pickers and conveyors continuously remove finished parts. Furthermore, inline vision or laser gauges verify critical dimensions in real-time. When a trend appears, the system flags or halts production. Therefore, corrective actions happen sooner rather than later. In addition, automation reduces idle time and operator fatigue. As a result, you sustain high throughput without sacrificing quality. Additionally, automated sorting and stacking simplify downstream logistics and packaging processes.

Maintenance strategy and lifetime tooling

Proper maintenance extends die life and maintains tight accuracy. Plan preventive maintenance on a cadence based on the number of strokes and material abrasiveness. Also, inspect punches, pilots, and stripping surfaces frequently. Replace wear parts before they create burrs or tolerance drift. Moreover, modular tooling enables you to swap worn stations quickly. Consequently, the mean time to repair falls, and uptime increases. Finally, track tool life data to optimise replacement intervals and reduce unexpected stops. Additionally, a parts-kitting strategy further shortens repair time.

Economic and production ROI of the metal die

Adopting progressive metal dies pays back through lower labour, less scrap, and higher output. Calculate ROI, including tool cost, reduced cycle time, and material savings. Moreover, consider softer gains, such as fewer quality incidents and a faster ramp-up. For many high-volume components, such as contacts, brackets, and stamped housings, the math favours using progressive dies within a few production runs. Therefore, plan trials, run capability tests, and scale proven setups to full production. Also, factor in reduced inspection labor and lower assembly time when modeling returns.

Practical implementation steps for a progressive metal die

Start with a feasibility study and cost model. Next, create a die layout that maximises nesting and minimises passes. Then prototype with a pilot run and capture SPC data. Also designed for maintainability with modular stations and accessible wear parts. Train operators on quick changeovers and basic troubleshooting. Finally, review cycle data and iterate on feed, lubrication, and tension control. By following these steps, progressive metal die technology will increase throughput, reduce costs, and deliver consistent parts on a larger scale.