Tool and die performance directly affects both production efficiency and product quality. Traditional dies often suffer from misalignment, wear, or inconsistent dimensions, which can increase scrap rates and slow production. Manufacturing facilities that do not employ high-precision components experience frequent downtime for inspection and adjustment. Integrating Precision Machining Parts ensures consistent alignment, minimizes wear, and maintains tight tolerances. In automotive stamping, precision components help achieve uniform material flow and reduce defective parts. This directly translates into lower operational costs and higher throughput, especially for high-volume manufacturing operations.

The Role of Material Selection

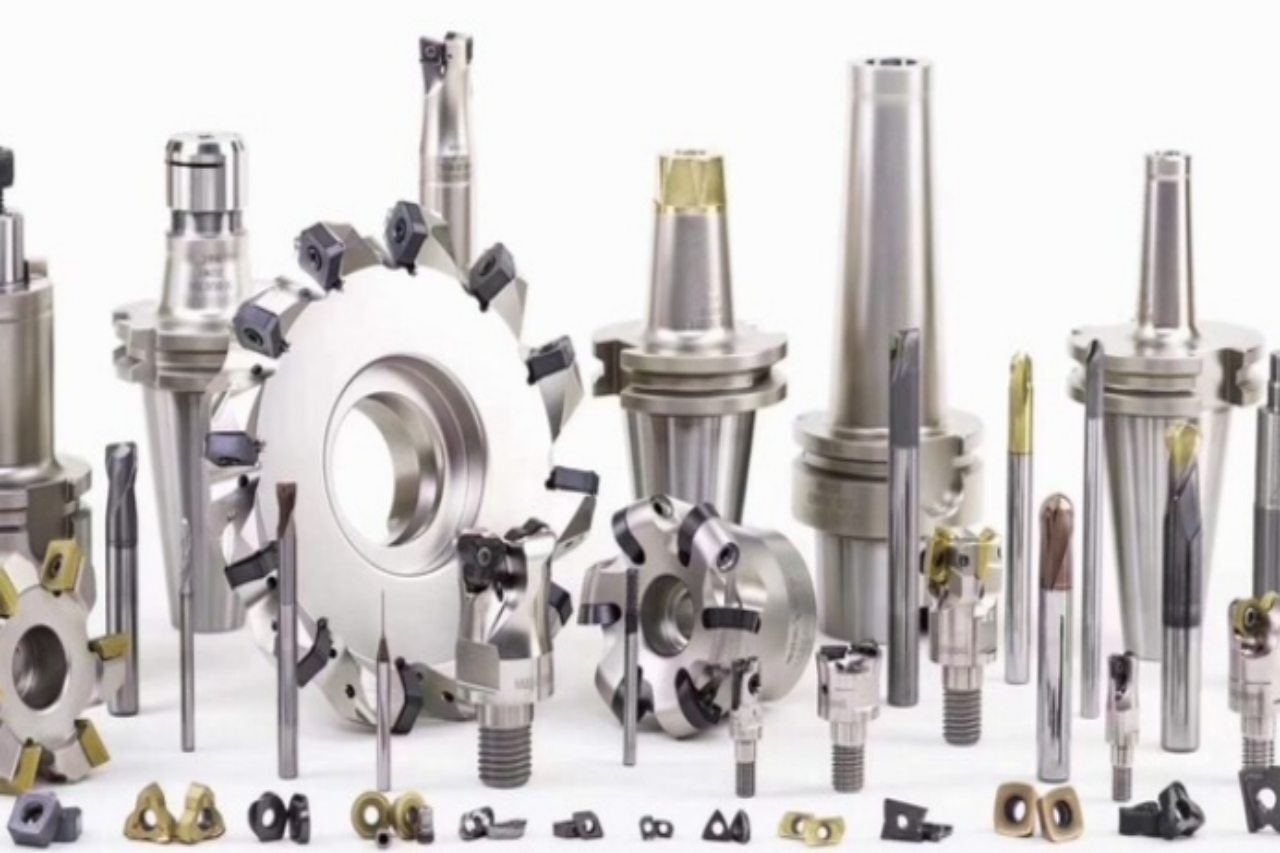

Material selection is critical in achieving long-lasting die performance. High-strength steels, alloys, and hardened metals are commonly used, but the machining process must maintain precise dimensions and surface finishes. Precision-machined parts made from these engineered materials offer durability, corrosion resistance, and dimensional stability under heavy loads. In aerospace tooling, guide pins and bushings made from hardened steel retain tolerances within ±0.01 mm over thousands of cycles. Selecting the right combination of material and precision machining reduces component failures, extends die life, and ensures consistent production quality.

Enhancing Dimensional Accuracy

Dimensional accuracy is essential for stamping, forming, and injection moulding operations. Minor deviations can result in assembly problems, rejected parts, or customer complaints. Precision-machined parts ensure tight fits between die components, resulting in consistent results in each press or mould cycle. For example, progressive dies rely on accurately machined guide pins and sliders to maintain strip alignment through multiple stations. This reduces cumulative errors, minimises scrap, and ensures all parts meet geometric and functional requirements. Facilities using precision components typically report a significant increase in first-pass yield and a decrease in rework.

Reducing Wear and Extending Lifespan

Wear is a significant factor affecting die longevity. Components with lower surface roughness reduce friction and heat generation. Precision-machined parts, such as polished guide pins, bushings, and punches, minimise wear and maintain dimensional stability over time. A midsize automotive stamping plant reported that replacing standard bushings with precision-machined components extended die life by 30% and decreased unplanned downtime. Reduced wear also keeps cutting and forming operations accurate, preserving product quality across long production runs.

Improving Assembly and Maintenance

Die assembly and maintenance are simplified with precision components. Precision-machined parts fit accurately, reducing installation errors and setup time. Maintenance schedules become predictable, as parts perform consistently under repeated stress. In electronics stamping, high-precision bushings reduced setup time by 25%, while ejector pins with precise tolerances reduced the need for frequent adjustments. Reliable component performance also lowers labour costs and increases production throughput. By streamlining assembly and maintenance, manufacturers can achieve higher operational efficiency without compromising quality.

Impact on Production Efficiency

Production efficiency improves markedly when precision components are used. Misaligned dies or worn parts can slow lines, increase scrap, and reduce yield. Precision-machined parts maintain alignment, lower defect rates, and allow presses or moulds to operate at higher speeds. In one high-volume stamping operation, precision components reduced scrap by 15% and increased throughput by 12%. The ability to operate consistently and reliably enables manufacturers to meet tight delivery schedules while maintaining high-quality standards, particularly in the automotive and aerospace industries.

Real-World Case Studies

Numerous case studies demonstrate measurable benefits. A stamping facility integrated precision-machined guide pins, bushings, and punches into their dies, resulting in a 20% reduction in downtime and an 18% decrease in defective parts within six months. An injection moulding manufacturer adopted precision-machined ejector pins and sliders, improving cavity alignment and reducing cycle time by 10%. These examples confirm that precision components enhance tool and die reliability, boost production efficiency, and improve product consistency, making them an essential investment for modern manufacturing operations.

Final Considerations on Precision Machining Parts

Investing in high-quality Precision Parts is critical for manufacturers aiming to optimise die performance. Ensure components meet stringent tolerance, hardness, and surface finish standards. Choose reliable suppliers with material traceability and post-machining inspection processes. Properly integrated precision components reduce maintenance needs, extend die life, and maintain consistent production quality. Manufacturers achieve higher throughput, lower operational costs, and long-term reliability. Ultimately, precision-machined parts deliver tangible benefits, enhancing tool and die performance and supporting sustainable, cost-effective manufacturing operations.