Precision grinding is one of the most fundamental steps in die manufacturing, a method that uses grinding wheels to achieve extremely tight tolerances and surface finishes. The process enables manufacturers to correct minor machining errors and achieve micron-level accuracy. For stamping dies, this means components that fit correctly, reduce wear, and consistently perform as intended.

How Precision Grinding Enhances Die Component Accuracy

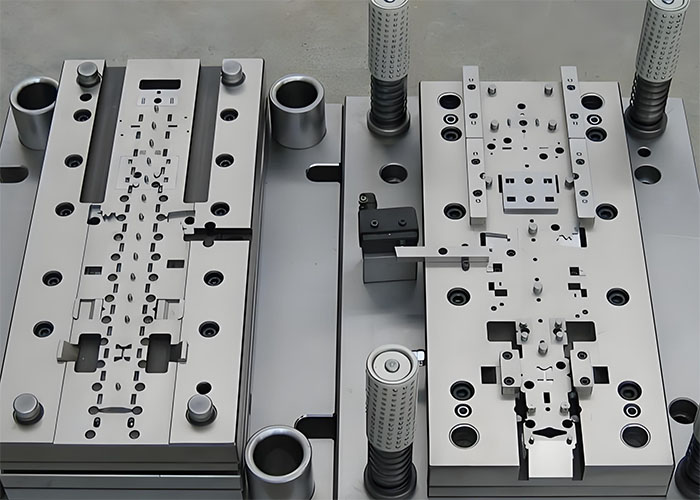

Accurate dies start with precise parts. Even the slightest misalignment can cause burrs, deformation, or part failure. Precision grinding removes this risk by ensuring flatness, squareness, and dimensional accuracy.

Furthermore, components that fit tightly reduce the risk of play during stamping cycles. This results in better repeatability and fewer defective parts. As stamping dies, operate under high-speed conditions, maintaining tight tolerances through grinding directly boosts production efficiency.

Surface Finish and Its Effect on Die Wear

The smoother the surface, the lower the friction. Precision grinding enhances the surface finish of die components, reducing friction between mating parts and between dies and workpieces.

Lower friction means less heat generation. In turn, this reduces the thermal expansion and premature wear of stamping dies. Over time, this contributes to longer tool life and less frequent maintenance cycles.

Precision Grinding for Tool Steel Hardness Management

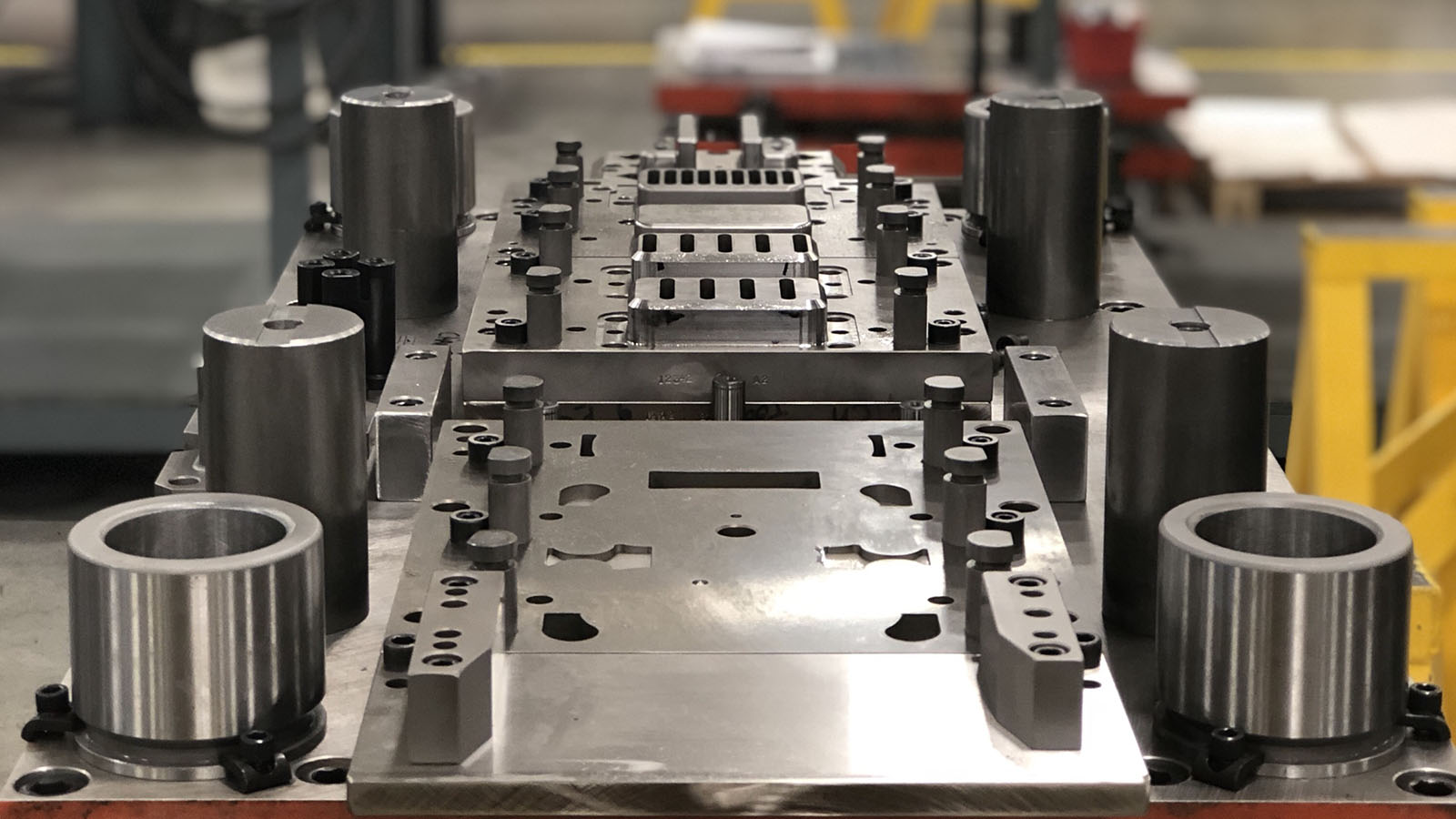

Tool steel hardness varies depending on the die function. Precision grinding can accommodate these hardness levels without compromising tool geometry. It allows accurate shaping of both soft and hardened steel components.

In many cases, grinding is the final step after heat treatment. This makes it crucial for achieving the desired dimensional finish without distorting the material. Stamping dies must retain both hardness and dimensional accuracy, and grinding bridges this gap effectively.

Improving Assembly and Fit with Ground Components

Assembly time and die performance both benefit from precision grinding. Ground components slide and align smoothly, reducing the time and effort needed during die assembly. This also lowers the chance of assembly-induced damage.

Moreover, well-fitted components reduce internal vibration and shock during stamping operations. Over time, this improves the lifespan of both the dies and the press machines. Better assembly fit also means faster repair and part replacement when needed.

Reducing Downtime through Predictable Tool Behavior

Consistency is key in high-volume manufacturing. Precision grinding contributes to this by ensuring dies perform predictably under load. Predictable wear patterns make it easier to plan maintenance, order replacement parts, and reduce unexpected downtime.

For companies relying on stamping dies for critical components, this predictability directly translates into better delivery timelines and customer satisfaction. Precision-ground dies lead to fewer surprises on the production floor.

Cost Savings and Operational Efficiency

While grinding incurs upfront costs, the long-term savings ultimately outweigh the initial expenses. Less frequent rework, longer die life, and reduced scrap all contribute to lower operational costs.

Additionally, precision grinding improves setup efficiency. Dies require less adjustment during changeovers, shortening downtime between runs. The result is higher throughput and better use of machine time.

Precision Grinding Value for Stamping Dies

Precision grinding plays a crucial role in enhancing the performance and longevity of stamping dies. From surface finish to dimensional accuracy, its impact is wide-ranging and quantifiable. By investing in precision grinding, moldmakers can ensure their products meet modern demands for speed, accuracy, and durability. As part tolerances become tighter and production speeds increase, the importance of this process will only increase.