Precision die cutting is a manufacturing method that produces clean, consistent parts with tight tolerances. It’s widely used in the electronics, automotive, and medical industries, where even a 0.01mm deviation can mean product failure. Manufacturers rely on this process for scalable, repeatable production. However, the secret behind every high-quality cut lies not in the cutting machine itself, but in the die, which determines every dimension and detail.

The Core of Precision Die Cutting is a High-precision Die

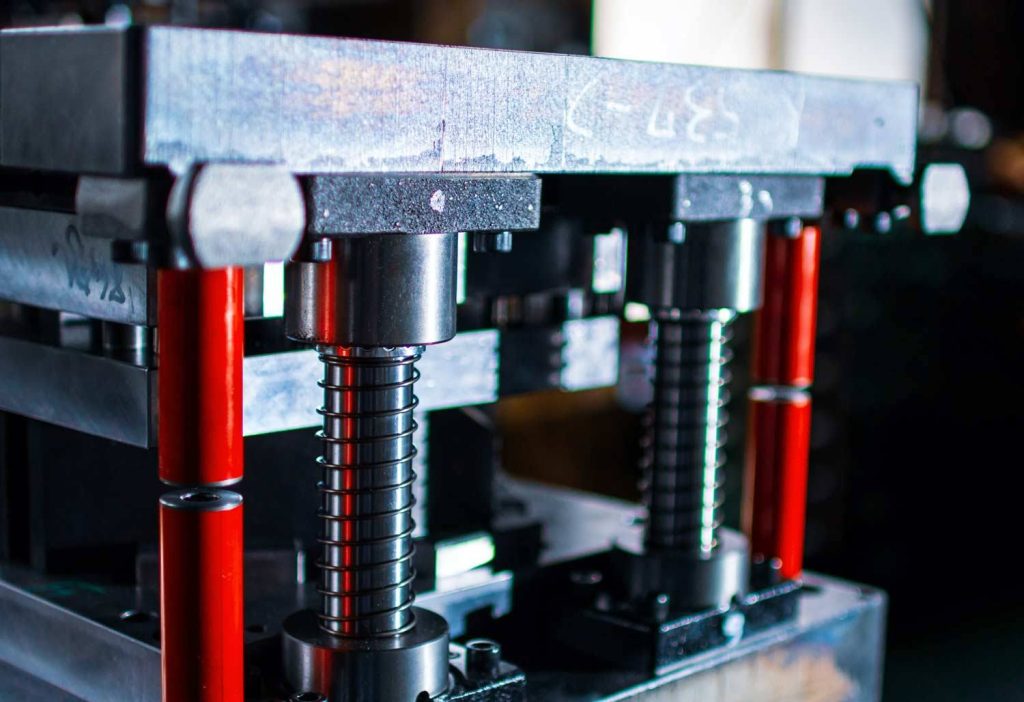

Every precision cut begins long before the cutting press moves. It starts with the die—crafted through exacting machining and grinding. A high-accuracy die ensures material alignment, uniform pressure, and sharp cutting profiles. Without this level of precision, burrs, misalignment, and dimensional drift occur, leading to waste and quality issues.

In other words, the stamping die is the heart of precision die cutting. Its geometry dictates edge definition, part repeatability, and tool longevity. A well-built die transforms an ordinary press into a precision instrument capable of mass-producing micro-level details at an industrial scale.

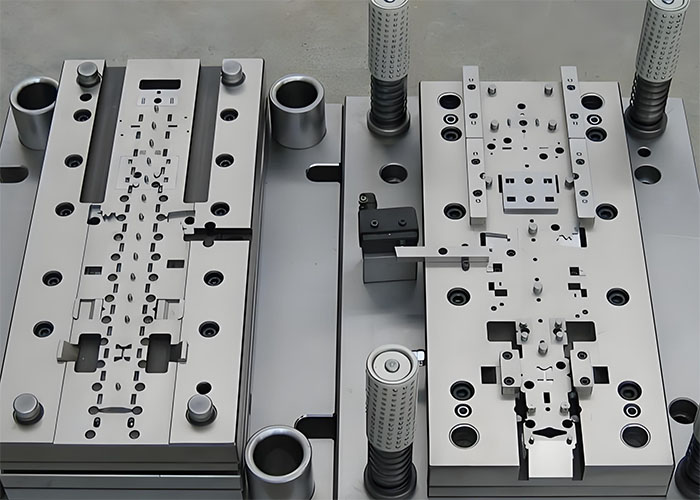

Precision Die Manufacturing Techniques Behind the Process

Creating such dies requires advanced manufacturing capabilities. Our technical expertise spans multiple high-precision processes:

- Jig and Coordinate Grinding: Achieves ultra-high accuracy on holes, slots, and contours, with roundness tolerance of ±0.001 mm.

- Wire EDM: Handles intricate geometries and tight internal radii without inducing thermal distortion.

- Profile and Surface Grinding: Produces mirror finishes and flatness within ±0.001 mm, essential for consistent cutting depth.

- CNC Machining and EDM Drilling: Enable repeatable, complex tool features for multi-layer die assemblies.

Each process contributes to dimensional integrity and long tool life, key requirements for Precision Die Cutting applications.

Material and Tooling Considerations in Die Cutting

Even the best machining process fails without the right material. The materials, such as SKD11, DC53, and tungsten carbide, are chosen for their hardness, wear resistance, and stability under stress. For cutting films or foils, SKD11 provides sharpness and cost efficiency. DC53 offers greater toughness and heat resistance for higher-cycle tools. Carbide, though more expensive, delivers unmatched longevity for demanding applications like metal or fibre sheet cutting.

Proper heat treatment and surface finishing further improve tool performance, preventing chipping and ensuring consistent clearance over thousands of cuts. This balance between material and manufacturing defines the durability and accuracy of every die.

Maintaining ±0.001 mm Accuracy in Tooling for Die Cutting

Maintaining a ±0.001 mm tolerance is not marketing talk—it’s a manufacturing discipline. Temperature control during machining, precision fixturing, and in-process measurement all ensure micro-level consistency. Coordinate measuring machines (CMMs) verify each component’s geometry before assembly.

High-accuracy dies minimise misalignment and maintain consistent cutting force distribution. This precision translates into better yield, reduced scrap, and faster setup times in Precision Die Cutting production. In high-volume industries, that level of reliability can save thousands of dollars per batch.

Case Applications

High-accuracy stamping dies power a wide range of cutting applications. In electronics, precision dies shape adhesive tapes, shielding foils, and flexible printed circuits (FPCs) used in smartphones and tablets. In the automotive industry, they cut insulation films, gaskets, and connectors that demand repeatable performance.

For example, in Type-C connector manufacturing, ultra-fine tolerances ensure a perfect fit between metal contacts and plastic housings. In medical devices, clean edges are essential for bio-safe film components. These use cases highlight how superior tooling directly impacts the consistency and reliability of end products.

Common Challenges in Precision Die Cutting Tool Design

Even with advanced machining, designing a reliable die is no simple task. Engineers must account for alignment precision, thermal expansion, and material springback—all of which affect final cut quality. Tool wear is another major challenge, especially when cutting abrasive materials like PET or copper foil.

Solutions include applying specialised coatings (e.g., TiCN or DLC) and integrating modular tool inserts for easy replacement. Advanced CAD/CAM simulation now allows designers to predict stress points and optimise clearance before machining begins, reducing trial-and-error time and improving first-pass yield.

The Link Between Precision Tooling and High-Yield Die Cutting

Precision Die Cutting succeeds only when supported by precision tooling. High-accuracy dies determine not just dimensional quality but also operational efficiency and cost per part. Manufacturers investing in superior die fabrication benefit from longer tool life, faster changeovers, and consistent product quality across millions of cycles. As industries move toward miniaturisation and high-density components, the demand for ultra-precise dies will only increase.