In the modern manufacturing world, precision is the foundation of quality. Even the smallest deviation from a design can result in malfunction, waste, or costly downtime. Custom precision machining provides the control needed to meet strict tolerances across various industries, from aerospace to electronics. Using advanced CNC systems, companies can maintain tolerances as tight as ±0.001 inches. This level of consistency ensures that each component fits perfectly and performs as expected, whether it’s part of an aircraft engine or a surgical tool.

Understanding the Process

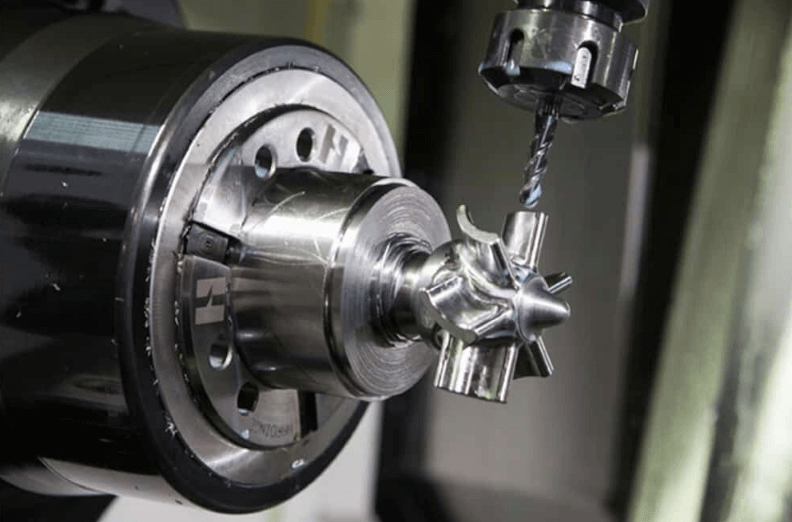

Custom precision machining begins long before the first chip is cut. Engineers start with CAD models that define every curve, angle, and hole of the final product. These designs are then translated into CAM programs that guide CNC machines through each operation. Milling, turning, drilling, and grinding occur in controlled environments to minimize vibration and error. Sensors monitor the process in real time, adjusting tool paths or speeds to ensure accuracy. This digital precision enables manufacturers to deliver parts that meet both functional and aesthetic standards.

Material Selection and Its Impact

Choosing the right material is crucial for high-quality machining. Aluminum is lightweight and easy to machine, making it ideal for automotive components. Stainless steel offers durability and corrosion resistance for medical or marine applications. Titanium, known for its strength-to-weight ratio, is essential in aerospace but demands specialized tooling and slower feed rates. Experienced machinists understand how each material reacts to heat, pressure, and tooling wear. By optimizing cutting parameters, they preserve the material’s integrity and surface finish, resulting in superior product longevity.

Advanced Equipment and Automation

Modern CNC machines redefine what’s possible in precision manufacturing. Five-axis machining centers allow complex geometries to be produced in a single setup. Robotic tool changers, real-time feedback systems, and adaptive control technology all contribute to consistency and speed. According to MarketsandMarkets, the global CNC machine tools market will surpass USD 120 billion by 2030, driven by automation and precision demands. Smart factories are adopting these systems to reduce human intervention while increasing repeatability. The combination of automation and skilled oversight ensures a steady output of flawless parts.

Quality Control and Inspection Standards

Every part produced through Custom Precision Machining undergoes multiple inspection stages. Coordinate Measuring Machines (CMMs) compare physical parts to CAD data, confirming dimensional accuracy within microns. Optical scanners, surface profilometers, and ultrasonic tools evaluate texture, hardness, and microstructure. Maintaining ISO 9001 or AS9100 certifications reinforces trust and ensures compliance with international standards. Quality isn’t a final checkpoint—it’s embedded throughout the machining process. Continuous monitoring allows manufacturers to catch deviations early, minimizing waste and ensuring customer satisfaction.

Efficiency and Cost Optimization

Precision doesn’t have to mean slower production. With optimized toolpaths and modern CAM software, custom precision machining reduces cycle times without compromising accuracy. Tool life management systems predict wear, preventing costly downtime. A 2024 industry report by Deloitte found that manufacturers using data-driven CNC optimization reduced material waste by 25% and improved production speed by 18%. Efficiency gains like these directly affect competitiveness, especially in markets where lead time and consistency define success.

Industry Applications and Real-World Results

Custom precision machining plays a vital role across industries. In aerospace, it enables tight-fitting turbine blades that withstand extreme heat. In medical manufacturing, it supports the production of surgical instruments and implants that meet strict biocompatibility standards. Electronics companies rely on it for precise housings and connectors, ensuring durability and reliability. In each case, the benefits are tangible—less rework, higher part quality, and better customer confidence. The method’s adaptability allows it to handle both prototype and mass-production runs efficiently.

Why Custom Precision Machining Ensures High Quality Parts

The true strength of Custom Precision Machining lies in its synergy between technology and expertise. By integrating CAD/CAM design, CNC automation, material science, and rigorous inspection, manufacturers achieve consistent, high-quality results.