Companies in the EV and aerospace sectors require parts that meet stringent tolerances, withstand harsh conditions, and arrive promptly. CNC machining delivers on those needs. It supports rapid prototyping. It also enables low-volume production and the fabrication of complex geometries in advanced alloys. For engineers, that combination accelerates design cycles and lowers technical risk. Below, I explain how CNC machining drives innovation, providing concrete examples and sources for verification.

Precision and tolerances that meet strict requirements

Modern aircraft and EV systems need parts machined to micron-level precision. CNC mills and multi-axis turning cells achieve tolerances that hand methods cannot match. As a result, engineers hit performance targets for bearings, housings, and structural brackets. For example, aerospace work routinely specifies tolerances of ±0.001 inch for critical components, which CNC shops consistently deliver. Consequently, designers rely on CNC machining to meet certification and safety margins.

Advanced materials machining for strength and weight savings

Lightweight alloys drive both industries. Aerospace uses titanium and Inconel for strength at low weight. EV manufacturers use aluminum and high-strength steels to cut vehicle mass. CNC machines handle these alloys with the proper tooling and process control. Moreover, research indicates that machining surface integrity is crucial for fatigue life in titanium and nickel alloys. Therefore, controlled CNC processes produce parts that meet fatigue and thermal requirements in engines and battery systems.

Rapid prototyping shortens design cycles

Product teams iterate quickly by moving from CAD to machined prototypes in days, not weeks. Digital manufacturers such as Protolabs and Xometry specialize in on-demand CNC runs for startups and OEMs. As a result, EV designers can test motor housings, mounts, and brackets early. Likewise, aerospace engineers can validate fit and function before committing to expensive tooling. Consequently, rapid CNC prototyping accelerates time to market and reduces costly late-design changes.

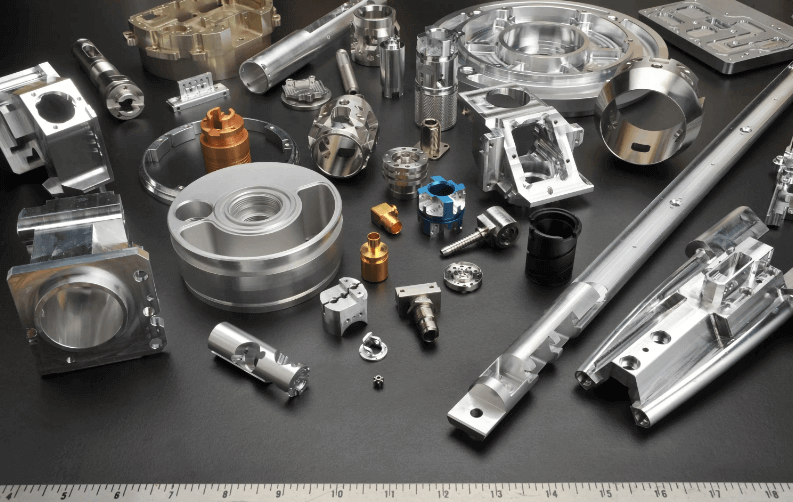

Complex geometries and multi-axis capability enable innovation

Multi-axis CNC enables teams to produce features that previously required assembly. Engineers can machine complex cooling channels, tight internal pockets, and curved surfaces in a single setup. Therefore, designers reduce part counts and join operations. In aerospace engines and EV power electronics, fewer joints mean fewer failure points. Additionally, advanced fixturing and CAD/CAM strategies enable the production of these complex parts at scale with repeatability.

Supply chain flexibility and low-volume production

EV startups and tier-one aerospace suppliers both need flexible suppliers. CNC shops provide short runs and fast turnarounds compared with hard-tooling methods. Consequently, firms scale production in a staged way—prototype, pilot, then ramp. Moreover, digital manufacturing platforms aggregate capacity, providing designers with access to global CNC capacity without the need for lengthy vendor searches. This flexibility reduces inventory risk and supports iterative design choices.

Quality control, inspection, and certification readiness

Aerospace and EV parts require traceable quality data. CNC providers integrate inline inspection, first-article reports, and coordinate measuring machine (CMM) validation. Therefore, suppliers deliver documented conformity for audits. In aerospace, documented process control supports FAA or EASA qualification steps. In EV powertrains and battery modules, consistent dimensional data reduces assembly variance and improves yield. As a result, CNC machining shops act as partners in certification, not merely vendors.

Real-world case studies showing measurable impact

Digital manufacturers highlight concrete wins. For example, a micromobility EV maker sourced half its parts through an on-demand CNC partner and sped production significantly. Similarly, aerospace parts machined from titanium and nickel alloys exhibit high surface integrity and reduced lead times, as reported in published case studies. These examples show how CNC machining delivers both performance and practical business benefits—faster launches, better assemblies, and predictable supply.

Actionable deployment tips for CNC machining parts

Start by defining your critical tolerances and materials. Then, choose suppliers with relevant alloy experience and multi-axis capacity. Next, run small prototype batches to validate fit and function. Also, require documented inspection plans and material traceability. Moreover, consider hybrid workflows—utilizing CNC for critical features and additive methods for complex cores—to optimize both cost and performance. Finally, plan supply continuity by using digital manufacturing platforms or multiple qualified shops. Following these steps lets you use CNC machining part approaches to accelerate innovation, control risk, and scale production reliably.