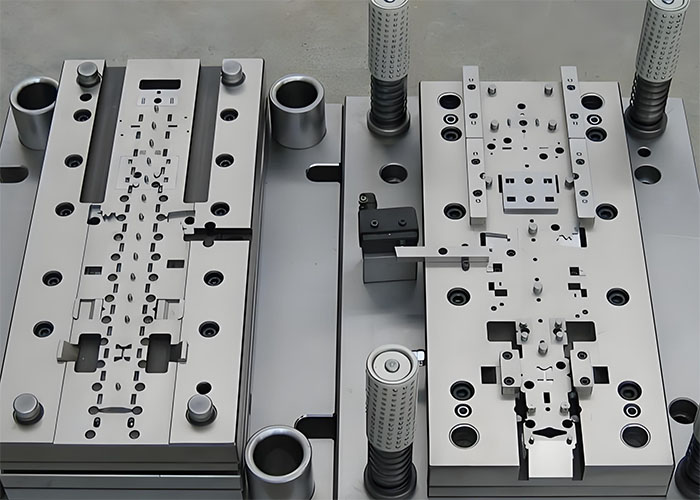

When manufacturing precision machining parts for our clients, we select the appropriate CNC machining strategy based on specific circumstances. The differences between 3-axis, 4-axis, and 5-axis machining affect geometric machining capabilities, tolerance control, surface finish, machining cycle time, fixture complexity, and overall cost. Chaoyang has many years of experience in precision parts machining, with a full range of CNC equipment, including high-speed YASDA machining centers (spindle speed up to 40,000 RPM, travel 300 × 420 mm, accuracy ±0.002 mm), AWEA and AGMA medium and large machining centers, and Vision Wild high-volume machining centers, enabling us to deliver precision machining parts with repeatable quality.

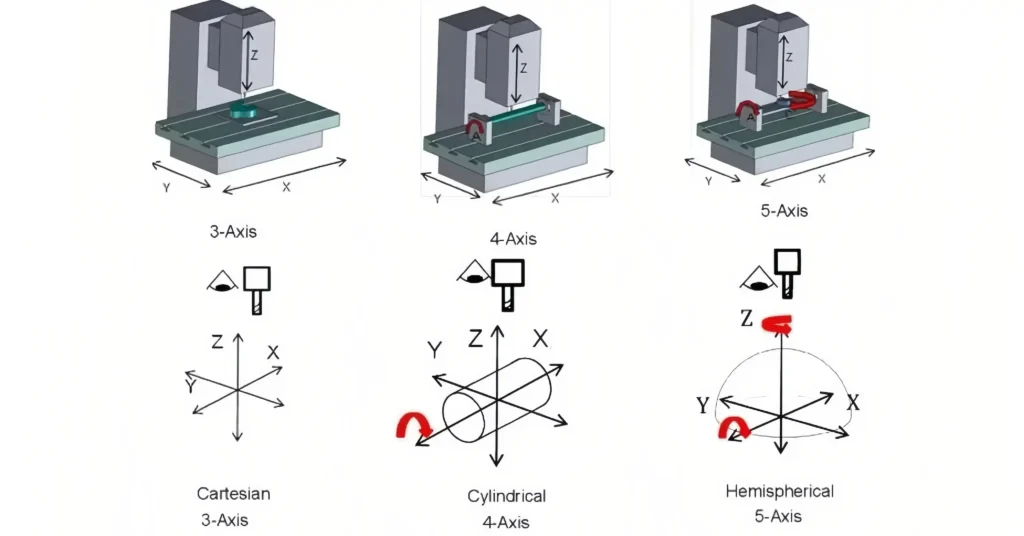

3-axis milling remains the preferred choice for many prismatic parts; 4-axis milling adds rotational capabilities, allowing cutting around the part’s axis, thus reducing the number of setups; while 5-axis milling provides simultaneous multi-directional cutting, minimizing fixture use, improving surface continuity, and reducing manual operations.

3-Axis, 4-Axis, and 5-Axis Machining Processes for Precision Machining Parts

In 3-axis milling, the tool moves along the X, Y, and Z axes, while the workpiece orientation remains fixed. This configuration is suitable for machining prismatic features, cavities, grooves, and simple contours, especially when the workpiece orientation can be adjusted to expose the desired surface and achieve predictable tool paths. Conversely, 4-axis machining adds a rotational axis (A-axis or B-axis) to rotate the workpiece or the worktable. This additional degree of freedom enables continuous cutting around cylindrical surfaces and reduces the number of secondary setups when machining features such as splines, grooves, and annular cavities.

5-axis machining provides two additional rotational degrees of freedom, typically the A and B axes or the A and C axes, allowing the tool to approach the workpiece from almost any direction. 5-axis machining enables actual simultaneous motion, with the tool and worktable moving in sync, resulting in smooth, continuous tool paths on complex surfaces. This capability is crucial for high-precision aerospace components, complex molds, impellers, and parts with deep cavities or steep walls.

Simply put, 3-axis programming and fixturing are simpler, and setup times are usually faster. 4-axis machining reduces the number of setups but requires rotating fixtures and indexing strategies. 5-axis machining significantly improves machining capabilities but requires advanced CAM software, skilled operators, and rigorous machine calibration. The final choice depends on the geometry, tolerances, surface finish requirements, and cycle-time targets of the precision machining part.

When should 3-axis machining be used for precision parts?

3-axis machining remains the preferred choice for many precision part machining tasks. It works best when precision parts have easily machinable surfaces, moderate chamfers, or allow economical and efficient indexing and multiple clamping operations. Its advantages include simple, straightforward CAM toolpaths, predictable cutting forces, and a wide variety of tools and fixtures. Three-axis milling machines excel at high-precision prismatic features (such as planes, orthogonal grooves, cavities, and through-holes), especially when combined with precision fixtures and finishing strategies.

However, 3-axis machining also has limitations. Machining deep cavities and steep walls requires longer tools, which can lead to tool deflection and chatter, affecting form accuracy and surface finish. Machining multi-sided parts requires multiple setups, each introducing potential positioning errors and cumulative tolerances. To mitigate these issues, Chaoyang employs the following methods:

- Using high-rigidity tools and minimizing tool overhang.

- Using climb milling for better surface integrity.

- Employing finishing processes with reduced radial depth and feed rates to control springback and tool deflection.

- Using modular fixtures and kinematic positioning to ensure repeatable setups.

When customers require fine surface finish and tight tolerances on small features, Chaoyang chooses YASDA high-speed machining centers.

4-axis machining reduces setup times and increases production efficiency.

4-axis machining adds a rotational axis, which is a significant advantage for machining precision parts with circumferential features or repeating patterns around an axis. In practical production, this enables indexing and continuous milling around a cylinder, reducing the need for secondary operations, shortening tool lengths, and improving the consistency of machining repeated features. The advantages of 4-axis machining include:

- Reduced clamping operations: Parts that previously required multiple fixtures to machine multiple surfaces can now be completed with fewer reclamping operations.

- Improved tool stability: Rotating the workpiece to present the cutting area allows for the use of shorter, more rigid tools, resulting in improved tolerances and surface finish.

- Cost-effectiveness: For many small to medium-volume production runs, 4-axis machining strikes a balance between capability and cost–especially when machining medium-sized parts on Chaoyang’s AWEA machining centers.

Of course, careful programming is also employed when using 4-axis machining, managing collision detection, tool path wrapping, and indexing tolerances in CAM software. Compared to multiple 3-axis machining operations, it can produce precision parts faster and reduce human error.

5-axis machining enables complex geometries and higher surface quality

When the geometry of a precision machining part limits the application of multi-fixture machining methods, or when surface continuity and minimal tool marks are critical, 5-axis machining is the preferred process. 5-axis machining allows the tool to tilt and rotate while moving along linear axes, resulting in smoother tool paths, reduced ripple height, shorter tool lengths, and avoiding the use of long-reach tools that can cause tool deflection.

The main advantages of 5-axis machining for precision parts are:

- Superior surface finish: Synchronous tool orientation maintains stable tool engagement, resulting in finer surface textures and fewer marks.

- Single-setup machining: Complex parts such as impellers, freeform molds, turbine blades, and medical implants often require only one setup, reducing cumulative positioning errors and improving geometric accuracy.

- Reduced manual finishing: Tighter machined surfaces minimize the need for subsequent polishing, grinding, or EDM operations.

Achieving consistent 5-axis machining results requires more than just powerful machining capabilities. Chaoyang utilizes CAM software with accurate, simultaneous algorithms, collision avoidance, and toolpath smoothing, as well as machines with high dynamic rigidity and thermal stability. In addition, Chaoyang’s Vision Wild and AGMA large machining centers provide the travel required for large precision part machining while maintaining the control accuracy needed for multi-axis synchronization. In addition, they integrate probing cycles for in-process feedback and adaptive toolpath correction, enabling tolerance control down to ±0.002 mm or lower.

Materials, Tools, and Process Parameters for Precision Machining Parts with Tight Tolerances

Material and tool selection significantly impact achievable tolerances and surface finish. More complex alloys, such as stainless steel, titanium, and tool steel, require slower cutting speeds and more robust tooling; lighter alloys, such as aluminum, allow for higher spindle speeds and feed rates, especially when machining with high-speed spindles like those from YASDA.

Therefore, tool selection is critical:

- Where applicable, Chaoyang uses high-quality carbide and PCD/PCBN to improve wear resistance and maintain sharp cutting edges.

- Short, rigid tools are selected to minimize deflection; shrink-fit or HSK tool holders are used for precise concentricity.

- Cutting parameters are optimized: conservative depths of cut are used for finishing, and high-feed strategies are employed for roughing to improve material removal efficiency when rigidity allows.

- Coolant and chip control: Directed high-pressure coolant and optimized chip breakers maintain thermal consistency and prevent chip recutting, which degrades surface finish.

For precision machining parts requiring ±0.002 mm accuracy, we employ finishing strategies that concentrate the machining of the final geometry into a single operation and control tool life to minimize operator intervention.

Selecting the Right CNC Machining Process for Precision Parts

3-, 4-, and 5-axis machining processes can all meet different manufacturing needs in the production of precision machining parts. From simple geometries to highly complex multi-surface parts, each machining method offers advantages in terms of accuracy, efficiency, and cost control. Chaoyang utilizes advanced equipment such as YASDA high-speed CNC machines and large-travel machining centers from Taiwan, enabling the ability to match the right machining solution to each application, ensuring tight tolerances, consistent quality, and scalable production.