High-precision projects require reliable tooling. Poor-quality tooling leads to scrap, downtime, and cost overruns. Conversely, experienced suppliers deliver consistent parts. Therefore, choosing the proper stamping die manufacturer is crucial. Here’s how to evaluate their capabilities, quality systems, and experience. We offer practical tips for selecting a partner that meets your precision requirements. Read on for practical guidance to ensure your stamping project is a success.

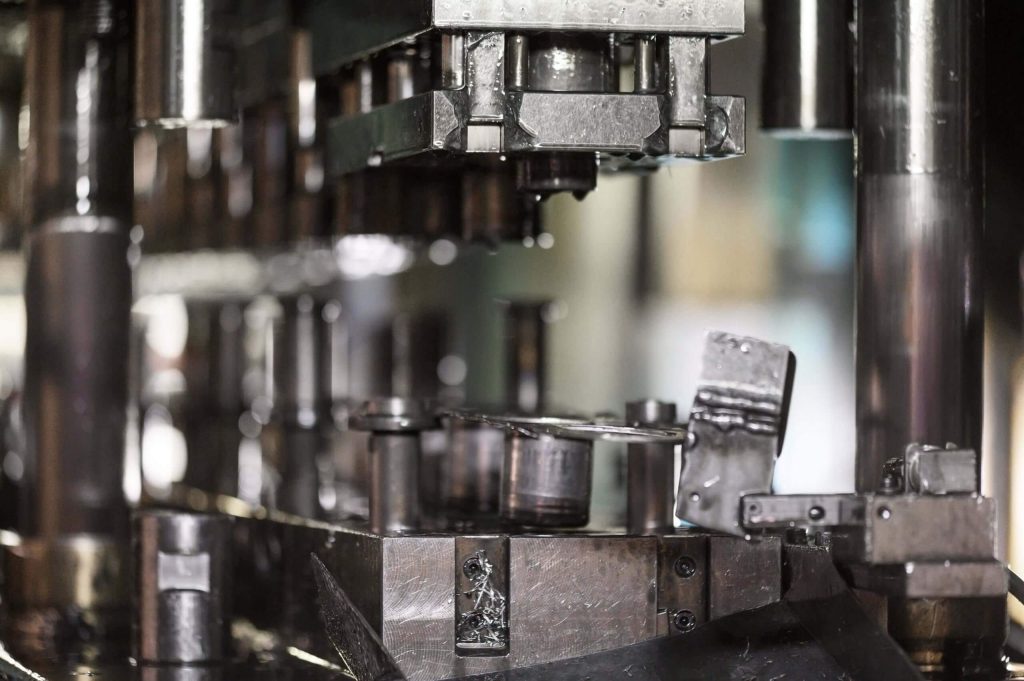

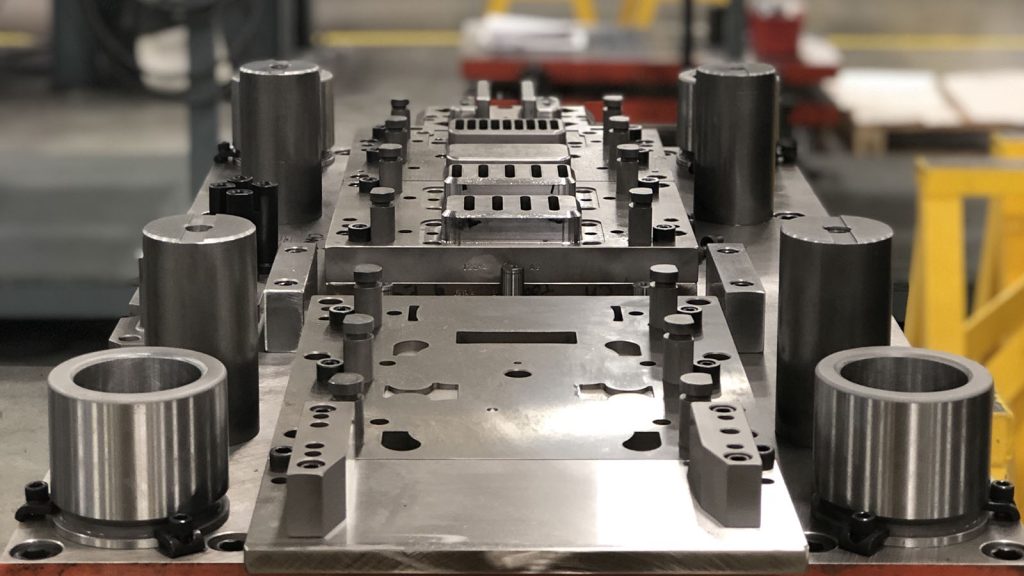

Assess Technical Capabilities

Start by reviewing the manufacturer’s equipment and technology. Do they use CNC machining, EDM, and precision grinding? Can they handle complex geometries and tight tolerances? Also, evaluate their simulation and prototyping capabilities. Consequently, you can gauge whether they can meet your project’s technical demands. Moreover, check their experience with the materials you plan to use. This helps avoid issues with wear, springback, or finishing. Ultimately, a well-equipped stamping die manufacturer can deliver accurate, repeatable results on time.

Evaluate Experience with Similar Projects

Past performance indicates future success. Ask for case studies or references from projects with similar precision or complexity. Additionally, verify their track record in industries such as automotive, electronics, or aerospace. Consequently, you can assess whether their expertise matches your project’s needs. Furthermore, check their problem-solving approach and responsiveness. Experienced teams anticipate challenges and proactively offer solutions. Therefore, you reduce the risk of delays and rework. Selecting a stamping die manufacturer with relevant experience ensures smoother project execution.

Quality Management and Certifications

Quality systems matter in precision stamping. Ensure the manufacturer follows ISO or industry-specific standards. Moreover, verify inspection capabilities, including CMMs and other metrology tools. Consequently, parts meet tolerance consistently. Also, ask about process documentation and traceability. This guarantees accountability for materials and processes. Furthermore, robust quality management reduces scrap and defects. Overall, a stamping die manufacturer with certified quality systems provides confidence in consistent output.

Material Knowledge and Compatibility

Not all manufacturers handle every material effectively. Verify their experience with steels, aluminum, copper, or specialty alloys. Additionally, consider the surface treatments and coatings that can be applied. Consequently, you avoid die wear, part deformation, or finishing problems. Moreover, proper material handling has a significant impact on tolerance and lifespan. Ensure the stamping die manufacturer understands metallurgy and the interactions with tooling. This knowledge supports high-precision outcomes and prolongs life.

Delivery and Production Capacity

Timely delivery matters in high-precision projects. Evaluate their production scheduling, capacity, and lead times. Also, consider flexibility for prototyping or urgent orders. Consequently, you avoid project delays and inventory issues. Furthermore, check how they handle scaling from small batches to full production. Efficient logistics and planning enable a stamping die manufacturer to meet both short-term and long-term demands.

Cost Considerations Without Compromise

Price is important, but quality and precision take priority. Beware of manufacturers offering unusually low bids. They may cut corners or use outdated processes. Conversely, reasonable investment in capable partners reduces defects and rework. Also, consider lifecycle costs, including maintenance, adjustments, and replacements. Consequently, choosing a stamping die manufacturer based on total value ensures project success and cost-efficiency.

Communication and Support

Clear communication reduces misunderstandings and errors. Assess responsiveness during inquiries and design discussions. Additionally, ensure they provide technical guidance and updates throughout the production process. Consequently, you stay informed and avoid surprises. Furthermore, a collaborative approach improves problem-solving. Selecting a stamping die manufacturer with strong communication practices strengthens project reliability and customer satisfaction.

Final Recommendations for Stamping Die Manufacturer

To select the proper stamping die manufacturer, begin by conducting a technical evaluation, reviewing their experience, and verifying their quality. Then, confirm material compatibility, production capacity, and delivery reliability. Also, consider total lifecycle costs and ensure clear communication throughout the process. Finally, seek references and validate past projects to confirm capabilities. By following these steps, you can ensure high-precision parts, reduce risk, and achieve smooth project execution with trusted Stamping Die Manufacturers. Chaoyang is an experienced stamping die manufacturer that integrates design and manufacturing. If you have mold customization needs, please don’t hesitate to contact us.