Manufacturing is all about precision, speed, and consistency. Yet, many factories still struggle with inefficiencies caused by manual setup and inconsistent tooling. Automation parts and jigs are revolutionizing how components are calibrated, fixed, and processed, ensuring every action on the production floor counts. As industries like automotive, electronics, and metal manufacturing continue to pursue lean operations, automated fixtures are essential to staying competitive. We’ll explore how precision automated components can improve workflow efficiency, reduce waste, and drive smarter production lines.

Consistency Through Precision Engineering

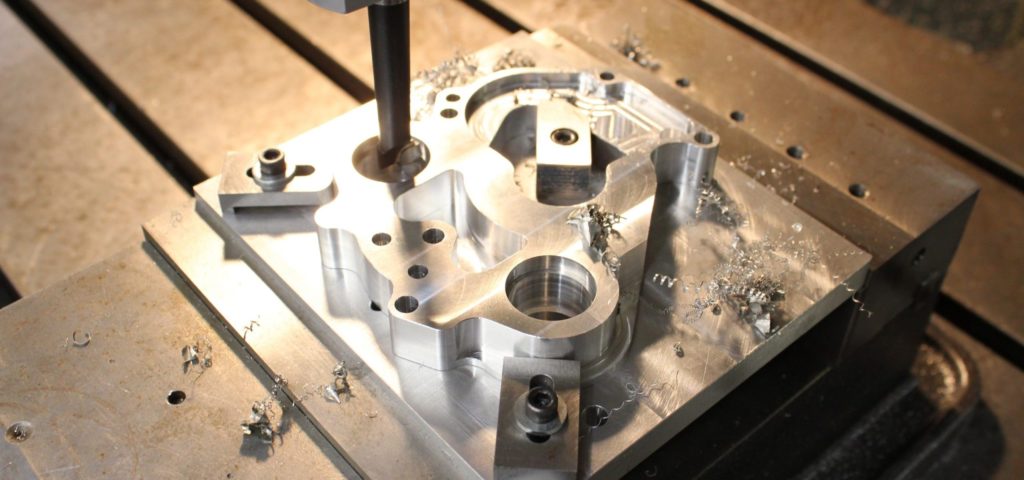

Jigs and fixtures guide, hold, and support workpieces during machining or assembly. When designed precisely, they eliminate variability caused by human error. For instance, in the automotive sector, customized jigs help ensure accurate positioning of panels, cutting rework costs significantly. Precision-engineered automation parts also integrate seamlessly with CNC machines, sensors, and robotic arms, enabling precise repeatability. This synergy minimizes alignment issues and maintains product standards even during large-scale production runs.

Reducing Human Error and Training Time

The automation part and jig simplify complex assembly operations. By fixing components in predetermined positions, they make it easy for operators with minimal training to perform high-accuracy work. A 2023 study by McKinsey found that manufacturers implementing automated jig systems reduced training time by up to 40%. This reduction not only saves cost but also speeds up the onboarding of new staff. Moreover, these systems reduce dependence on highly skilled labor, creating a more stable production environment in industries facing labor shortages.

Boosting Speed Without Sacrificing Accuracy

Speed and precision rarely go hand in hand in traditional setups. However, Automation Parts and Jigs bridge this gap. Automated jig systems allow multiple operations—such as drilling, cutting, or welding—to co-occur with minimal repositioning. In electronic component assembly, for example, custom automation jigs ensure micro-level accuracy while maintaining production rates above 90% efficiency. By reducing the need for manual adjustments, these systems prevent delays and improve cycle consistency.

Enhancing Flexibility in Production Lines

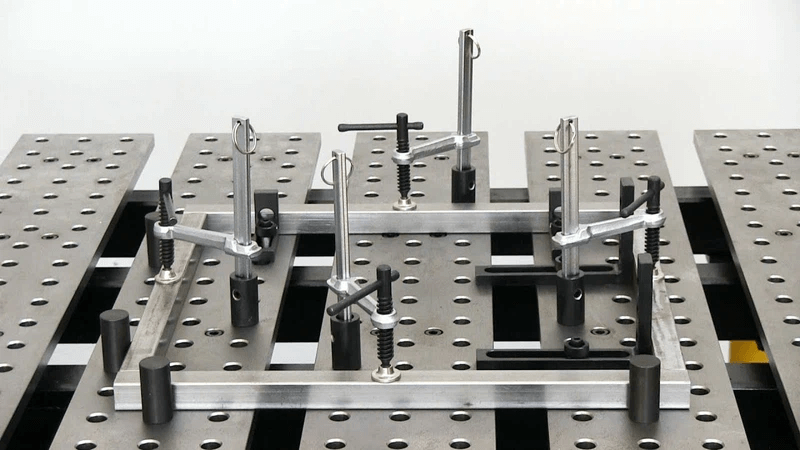

Modern jigs and fixtures are no longer static. With modular designs and quick-change systems, they adapt to different products and batch sizes. This flexibility is crucial for manufacturers producing multiple SKUs or custom parts. According to Bosch Rexroth, modular automation jigs can reduce setup changeover times by 50%. Manufacturers can respond faster to market demands without extensive retooling. Such adaptability gives companies a competitive edge in dynamic markets where responsiveness matters as much as precision.

Lower Maintenance and Higher Reliability

Automation Parts and Jigs are built for endurance. They use durable materials such as hardened steel, aluminum, and polymer composites that withstand vibration, pressure, and wear. Routine maintenance is simpler too—modern jigs often feature sensor feedback that alerts operators when alignment drifts or torque levels deviate. Predictive maintenance using IoT-enabled jigs can cut unexpected downtime by up to 30%. This reliability extends machine lifespan and helps manufacturers maintain steady production without interruptions.

Automotive and Electronics Manufacturing

In the automotive industry, Toyota integrates automated jigs for robotic welding, achieving consistent precision across thousands of chassis frames daily. Similarly, electronics manufacturers like Foxconn employ customized automation parts for PCB assembly, reducing defect rates by nearly 20%. These examples demonstrate the tangible impact of automation systems when integrated thoughtfully. They also highlight that efficiency gains are not limited to large corporations—small and medium manufacturers can achieve similar benefits with scalable jig solutions.

Driving Future Growth with Automation Parts and Jigs

As industries push toward smarter, data-driven production, Automation Parts and Jigs will play an even bigger role in shaping efficiency. Their integration with AI, sensors, and digital twins allows real-time feedback and optimization. Manufacturers leveraging this combination will continue to reduce waste, cut costs, and deliver consistent quality. In essence, Automation Parts and Jigs are not just tools—they are the enablers of modern productivity, bridging precision engineering with intelligent automation to drive sustainable manufacturing growth.