As demand for lighter, smaller, and more complex parts grows across industries, precision stamping dies are becoming increasingly important. Precision stamping dies are used to ensure consistent shapes, tight tolerances, and minimal defects in mass production. These dies play a crucial role in manufacturing parts for compact electronic devices, lightweight automotive components, and efficient energy systems.

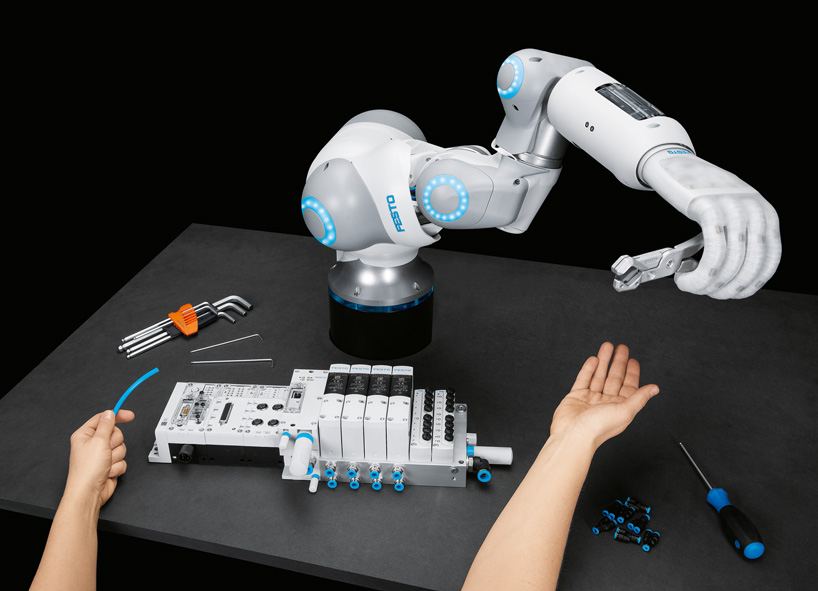

Robotics Components Require Precision Without Compromise

The robotics industry demands repeatable accuracy. Components like robotic arms, joint housings, or servo casings must align with sub-millimeter tolerances. Any deviation affects movement precision and long-term reliability. Here, precision stamping dies make a critical difference.

By ensuring consistent press results across thousands of units, these dies help maintain strict symmetry and surface quality. Robots used in automotive manufacturing or precision medical devices depend on the fine geometry that these dies deliver. In this way, stamping tools serve as hidden enablers of intelligent automation.

How the Automotive Sector Benefits from High Precision Dies

In automotive manufacturing, structural strength and design innovation are closely intertwined. EV battery enclosures, chassis reinforcements, and EMI shielding parts must be robust yet lightweight. Precision stamping dies allow automakers to meet safety and efficiency regulations without compromising mass production speed.

These dies also support fine feature definition in components like connector shields or panel fasteners. As the industry shifts to electric platforms and lighter body designs, high-accuracy stamping has become a necessity. Without such tooling, key technologies like ADAS modules or compact connectors wouldn’t scale effectively.

Metal Dies in Consumer Electronics and Connectors

The trend of miniaturization drives the consumer electronics industry. From smartphone frames to USB-C terminals, every millimeter counts. The Precision stamping die enables manufacturers to produce highly detailed metal parts at scale while maintaining their strength and conductivity.

In connectors, even minor misalignments can lead to performance failures. Dies with micro-level consistency prevents these errors. Moreover, with high-run production cycles, die durability and heat resistance matter. Leading electronics suppliers rely on high-quality dies to ensure device reliability and maintain a strong brand reputation.

Industrial and Telecom Equipment Needs High Structural Integrity

Telecom cabinets, 5G base station supports, and industrial control units face demanding structural requirements. Components often involve multi-layered assemblies and demand high punching precision. Precision stamping dies enable the formation of these parts with intricate geometries while maintaining uniformity.

Advanced multi-station progressive dies to streamline fabrication, reducing material waste and improving alignment. This is especially crucial in high-density telecom and data infrastructure, where even slight inconsistencies can compromise thermal management or electromagnetic shielding.

Energy Sector and Sheet Metal Challenges

From solar panel brackets to battery module casings, the energy industry is increasingly relying on precision stamping dies. These components often involve thin metal sheets with wide spans, requiring dies that prevent distortion during the forming process.

High-strength alloys, heat resistance, and corrosion protection all add complexity. Dies tailored to energy sector applications must manage material spring back and dimensional stability. With renewable energy driving efficiency at scale, precision tooling is crucial for both assembly speed and component longevity.

Versatile Die Solutions for Diverse Production Needs

No two industries are identical, and neither are their tooling demands. The shift toward customization has elevated the value of precision stamping dies tailored to individual needs. Manufacturers increasingly need dies designed for unique part geometries, volumes, and materials.

This is where engineering and design capabilities become differentiators. Providers who offer in-house simulation, rapid prototyping, and tight process control help clients reduce lead time and cost. As global supply chains demand more agility, high-performance die partners provide a competitive advantage.

High-quality precision stamping dies improve part quality

As the industry develops, the demand for precision parts is increasing steadily. However, we must still keep in mind one principle: better molds can produce better parts. Precision stamping molds can achieve complex shapes, reduce tolerances and improve reliability to support next-generation manufacturing. Whether you are manufacturing electric vehicles, smart devices or 5G infrastructure, the right molds can improve performance and scalability.