Tight-tolerance components sit at the core of advanced engineering, especially in aerospace, medical devices, and precision tooling. These parts demand accuracy that often reaches ±0.005 mm or even tighter. Manufacturers rely on CNC Machining and precision grinding to get these dimensions with consistency. Each process brings unique strengths, limitations, and ideal application scenarios. This article breaks down both methods so engineers and buyers can choose the right one for their projects without guesswork.

How CNC Machining Delivers Dimensional Accuracy

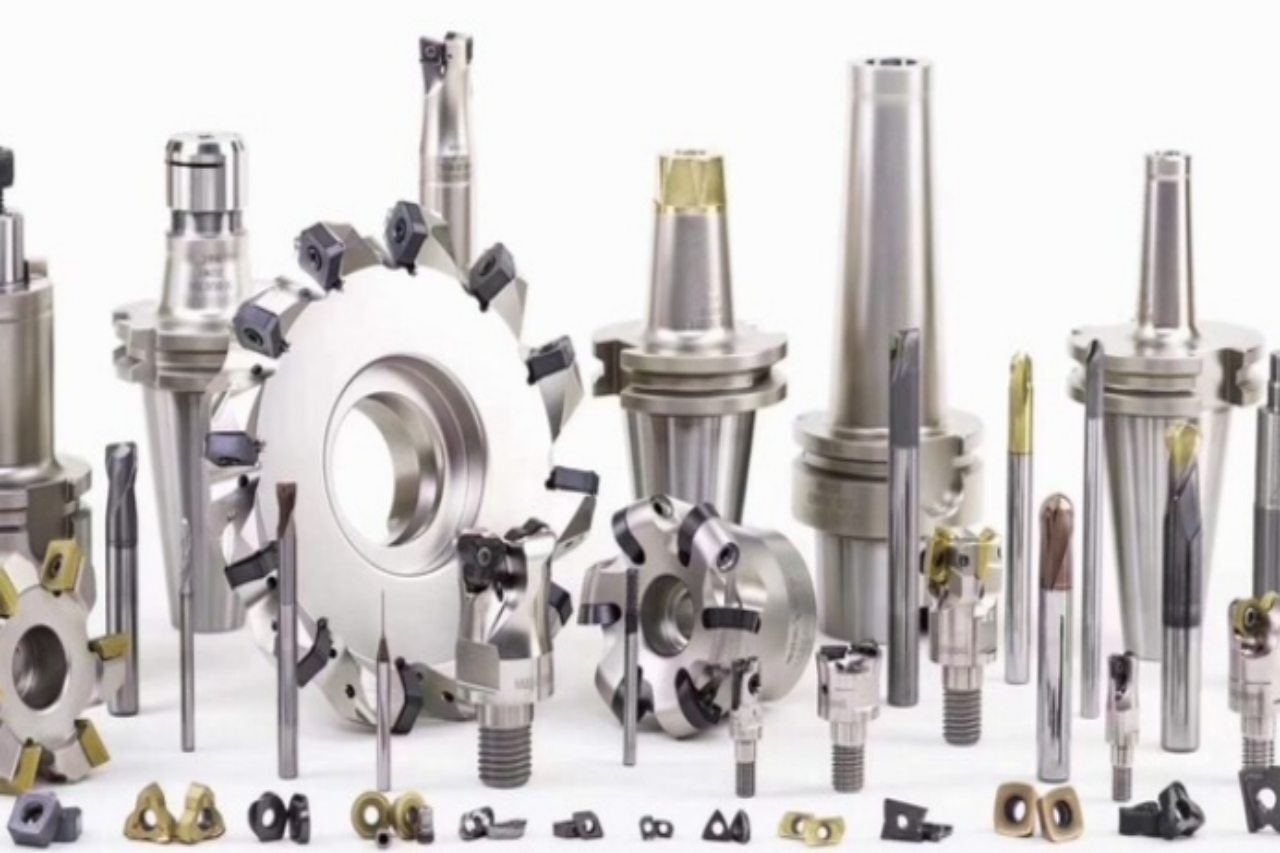

CNC Machining uses programmed toolpaths to remove material with high repeatability. Modern 5-axis machines position tools with micrometer-level control. They handle complex geometries efficiently, including deep pockets, contoured surfaces, and multi-angle features. Machinists adjust speeds, feeds, and tooling to maintain accuracy even on hard materials such as stainless steel or titanium. The process also supports high tool flexibility. One setup may allow milling, drilling, tapping, and contouring. This versatility makes CNC machining ideal for prototypes, low-volume batches, and parts with complex three-dimensional shapes.

Where CNC Machining Meets Its Practical Limits

Despite its strengths, CNC Machining has limits in final dimensional refinement. Tool wear can affect tolerances over long cycles. Micro-vibrations reduce consistency when tolerances go below ±0.002 mm. Cutting heat may cause surface distortion if not managed through coolant or adaptive toolpaths. Additionally, extremely tight surface roughness values (such as Ra 0.1 μm) often remain out of reach. CNC Machining gets parts close, but many industries still rely on grinding for finishing. This creates a workflow in which machining provides shape and grinding offers perfection.

Precision Grinding and Its Core Strengths

Precision grinding removes small amounts of material using abrasive wheels. The process achieves extreme accuracy and mirror-like finishes. Cylindrical grinding can reach roundness tolerances below 0.001 mm. Surface grinding easily hits flatness values better than 0.002 mm. These results make grinding the final step for critical components such as gauge blocks, die inserts, bearing races, ejector pins, and core pins used in high-precision molds. Grinding excels on hardened steels. Heat-treated materials maintain their stability, allowing grinding to deliver consistent results without deformation.

When Precision Grinding Outperforms CNC Machining

Grinding becomes essential once tolerances enter the ultra-precision range. Applications such as aerospace hydraulic spools, medical surgical tools, and semiconductor tooling require surfaces with minimal friction and precise geometry. Grinding also provides edge control far beyond typical machining. In progressive die components, for example, punch heads, guide pins, and form inserts often rely on grinding to achieve perfect squareness and edge sharpness. While CNC Machining can approach desired dimensions, grinding locks them in with unmatched stability and repeatability.

Choosing the Right Method Based on Component Geometry

The geometry of a component strongly influences the choice between machining and grinding. CNC Machining handles 3D contours, curved surfaces, and complex cavities effectively. Grinding works best on flat, cylindrical, or uniform surfaces. Many precision mold and stamping die components use both methods. A cavity insert may begin with CNC Machining for the overall shape and then move to grinding for the shut-off surfaces. A guide pin might start as a turned part, followed by centerless grinding to achieve tight diameter tolerances. Matching the method to the geometry ensures efficiency without sacrificing accuracy.

Real Application Scenarios Across Industries

Different industries demand different combinations of CNC Machining and grinding. Medical implant manufacturers often machine titanium for initial shapes, then grind articulation surfaces to ensure smooth movement. Automotive manufacturers grind camshaft lobes to achieve wear-resistant profiles. Semiconductor fixture makers use CNC Machining for large pockets and alignment features, then rely on precision grinding for datum planes. These mixed-process workflows help avoid high cost while maintaining tolerances that remain non-negotiable for product performance and safety.

Key Takeaways on CNC Machining vs. Grinding for Tight-Tolerance Components

Both CNC Machining and grinding deliver accuracy, but each shines in different stages of production. Machining offers flexibility, speed, and control over complex geometry. Grinding delivers ultra-tight tolerances and exceptional surface finishes. Engineers often combine both methods to achieve optimal results in demanding industries. When selecting a process for tight-tolerance components, consider geometry, material hardness, required surface finish, and overall production volume. The right choice ensures stable quality and efficient manufacturing while maximizing performance across critical applications.