Manufacturers rely on stamping dies to create precise metal parts at scale. These dies operate under intense stress. Therefore, tool steel selection directly shapes performance, uptime, and part quality. Many engineers know the familiar names—D2, A2, or M2—but few understand why each grade behaves differently. I will now provide a detailed introduction to tool steels used in stamping dies and explain the optimal application scenarios for each type.

High-Carbon High-Chromium Steel

D2 tool steel remains one of the most common choices for stamping applications. It delivers high wear resistance due to its 12% chromium content. This level approaches stainless steel composition, yet D2 still offers the strength needed for cutting and forming. Shops often select it for medium- to high-volume runs. However, its toughness is mid-range. Tools may chip if the die handles thick or high-strength materials. Heat treatment also affects D2’s stability. The steel can reach 58–62 HRC, which supports long tool life in stable production environments.

Oil-Hardening Tool Steel

O1 is widely used for prototypes or low-volume stamping dies. It costs less than high-chromium grades and machines easily. Many tool rooms prefer O1 for quick-turn projects. Although it reaches 57–60 HRC, its wear resistance does not match that of D2 or powdered steels. It performs best with mild steels, copper, or aluminum alloys. Because O1 hardens in oil, distortion is predictable, reducing finishing time. Yet engineers must avoid using O1 in high-pressure forming or abrasive environments. It simply cannot withstand the extreme loads of advanced materials like dual-phase steel.

Air-Hardening Steel

A2 tool steel offers a balanced performance profile. It shows more toughness than D2 while keeping good wear resistance. Many stamping dies using A2 benefit from reduced cracking risk during edge impact or misalignment events. A2 hardens in air, reducing distortion and improving dimensional stability. Typical hardness ranges from 57–60 HRC. Shops choose A2 for forming dies, draw dies, and cutting dies that handle moderate production volumes. For teams that need a “middle-ground” steel, A2 often provides the best life-cycle cost without overspending.

High-Speed Steel

M2 high-speed steel is used in stamping dies when heat and abrasion dominate. It contains tungsten and molybdenum, which help the steel maintain hardness at high temperatures. Cutting edges stay sharp even under aggressive conditions. M2 reaches 60–65 HRC, exceeding the hardness of most conventional tool steels. Manufacturers use it for high-speed blanking, intricate piercing tools, and high-strength steel stamping. Its primary weakness is cost. M2 is more expensive and more complicated to machine. But for stamping dies in advanced automotive applications, the investment pays back through longer uptime.

Powder Metallurgy Steels

Powder-metallurgy steels such as CPM-M4 and CPM-D2 enhance performance in demanding operations. Their microstructure is uniform due to the PM process, thereby preventing the formation of large carbide clusters. This structure increases wear resistance and reduces chipping. PM steels perform exceptionally well in stamping dies used on abrasive stainless steels, electrical steel, or coated metals. They often outperform standard steels by 30–50% in tool life, according to published manufacturer data from Crucible Industries and Bohler-Uddeholm. Although the upfront cost is high, PM steels reduce unplanned downtime, which helps high-volume factories maintain delivery schedules.

Shock-Resistant Steels

S7 tool steel stands out when toughness matters more than wear resistance. Engineers use it for stamping dies that are exposed to repeated impacts, misfeeds, or vibration. S7 reaches about 54–56 HRC. Its lower hardness helps it absorb shock without cracking. Many tool shops use S7 for shear blades, trim dies, or forming tools in heavy-duty environments. It is also common in the production of automotive frames and chassis parts, where large panels generate high-impact forces. When a die fails due to breakage instead of wear, switching to S7 often prevents future downtime.

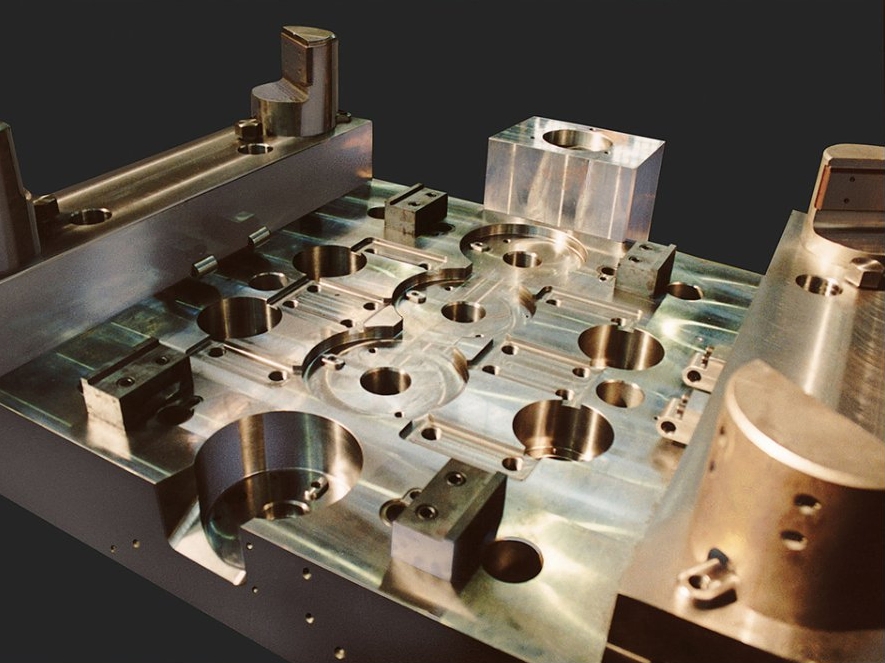

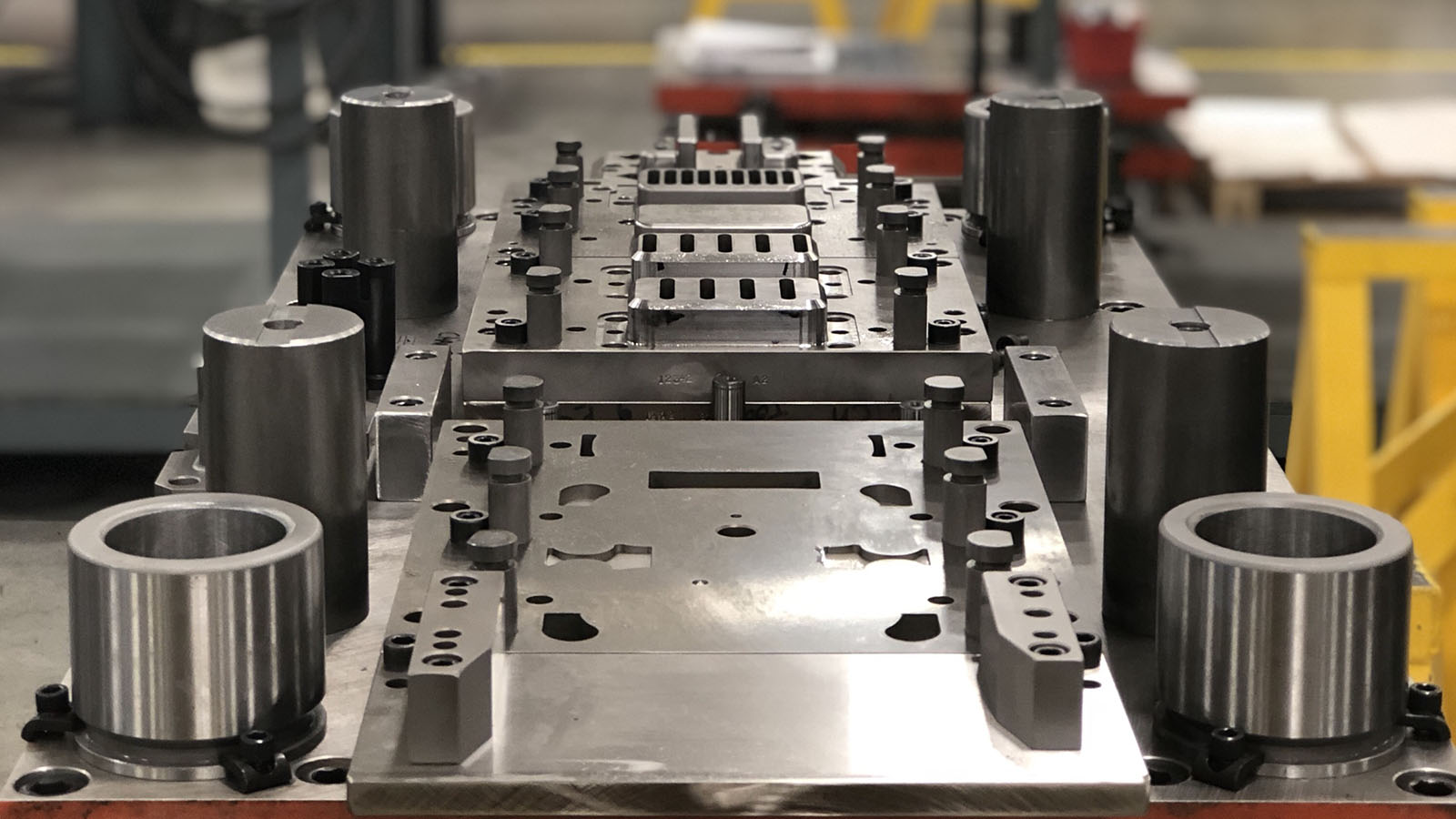

Using Stamping Dies

Choosing the right tool steel for a stamping die requires understanding the stress conditions, production volume, and material type. D2 handles wear, A2 balances toughness, M2 maintains hardness at high temperature, PM steels deliver maximum durability, and S7 absorbs impact. Each grade has a clear role. Teams that match steel properties with their actual production environment often cut maintenance costs and reduce tool failure. Because modern stamping dies face tougher metals and higher speeds, selecting the proper steel is no longer optional—it is essential for reliable, long-term manufacturing results.