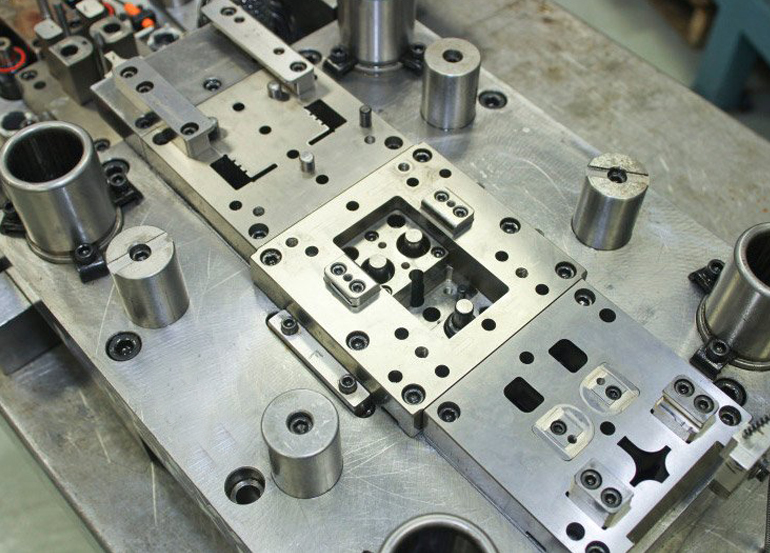

Tooling maintenance remains one of the most significant cost factors in manufacturing. Traditional steel dies are prone to wear, corrosion, and alignment drift. These problems require frequent inspections, lubrication, and occasional part replacement. In high-volume operations, even minor delays can cause significant losses. By introducing a Plastic Die Base into the tooling structure, manufacturers can reduce many of these recurring issues. A Plastic Die Base offers lower friction, better corrosion resistance, and more stable dimensional performance over time. These material advantages directly decrease maintenance frequency, minimize downtime, and extend the operational lifespan of tooling systems.

Advantages of Lightweight Materials

Lighter materials reduce mechanical stress on the entire die assembly. Steel bases, while strong, add considerable weight, increasing wear on guide pins, punches, and moving components. Plastic die bases, being significantly lighter, reduce these stresses. This leads to slower component degradation and fewer part replacements over time. Handling and installation also become easier, reducing labor costs and the risk of installation errors. For example, in a midsize stamping operation, replacing a steel die with a plastic die base reduced installation time by approximately 40%, directly lowering labor hours.

Corrosion Resistance and Longevity

Metal bases are prone to corrosion in humid or chemically aggressive environments. Rusted or pitted surfaces can cause misalignment and increased friction, shortening die life. Plastic die bases resist oxidation and chemical attack, maintaining surface integrity even in challenging conditions. This resistance eliminates the need for frequent cleaning or protective coatings. Several manufacturers report that switching to plastic bases in their stamping lines reduced corrosion-related downtime by nearly 30%. Consequently, maintenance crews can focus on preventive inspections rather than constant cleaning or repair.

Reduced Lubrication Needs

Lubrication is a routine necessity for steel dies. Without regular oiling, friction increases and components wear faster. Plastic die bases have self-lubricating properties or inherently low friction coefficients, significantly reducing or eliminating the need for lubrication. This not only saves material costs but also reduces labor involved in applying and cleaning oils. Over a year, a production facility using plastic die bases reported saving over 200 labor hours previously spent on lubrication tasks, enhancing both efficiency and cost-effectiveness.

Dimensional Stability and Accuracy

Precision is critical in tooling operations. Steel bases expand and contract with temperature changes, potentially causing misalignment. Misaligned dies require recalibration, increasing labor and downtime. Plastic die bases, particularly high-performance polymers, maintain dimensional stability under temperature and stress. This stability protects dies and punches, reducing the risk of premature wear. In one automotive stamping plant, switching to plastic bases improved die repeatability and reduced recalibration frequency by 35%, directly impacting production efficiency and product quality.

Impact on Production Downtime

Downtime is costly. Every unplanned stop reduces throughput and raises production costs. Plastic die bases lower maintenance frequency, ensuring more consistent operation. Reduced maintenance and recalibration mean operators spend less time troubleshooting and more time producing. Continuous production not only improves output but also minimizes scrap rates. In electronics assembly, facilities using plastic bases experienced fewer misaligned cuts, resulting in fewer defective products and less rework labor. The combined effect is measurable savings and improved operational reliability.

Real-World Case Studies

Several companies have documented the benefits of using plastic die bases. An electronics assembly line replaced steel bases with engineered polymers, resulting in a 25% reduction in maintenance downtime over six months. Another automotive manufacturer saw a 30% increase in die lifespan while lowering lubrication costs. Smaller operations also report faster installations, less punch wear, and fewer alignment adjustments. These case studies highlight that material choice significantly affects both maintenance costs and overall production efficiency.

Final Considerations on Plastic Die Base

Evaluate strength, wear resistance, and thermal stability before purchasing. Consider supplier support and material certifications to ensure compatibility with your production environment. Proper selection reduces maintenance frequency, lowers labor costs, and extends die lifespan. By investing in a high-quality plastic die base, manufacturers achieve consistent production, lower operational expenses, and improved product quality. Ultimately, a plastic die base is not just a replacement material—it is a long-term solution for cost-effective, high-precision tooling operations.