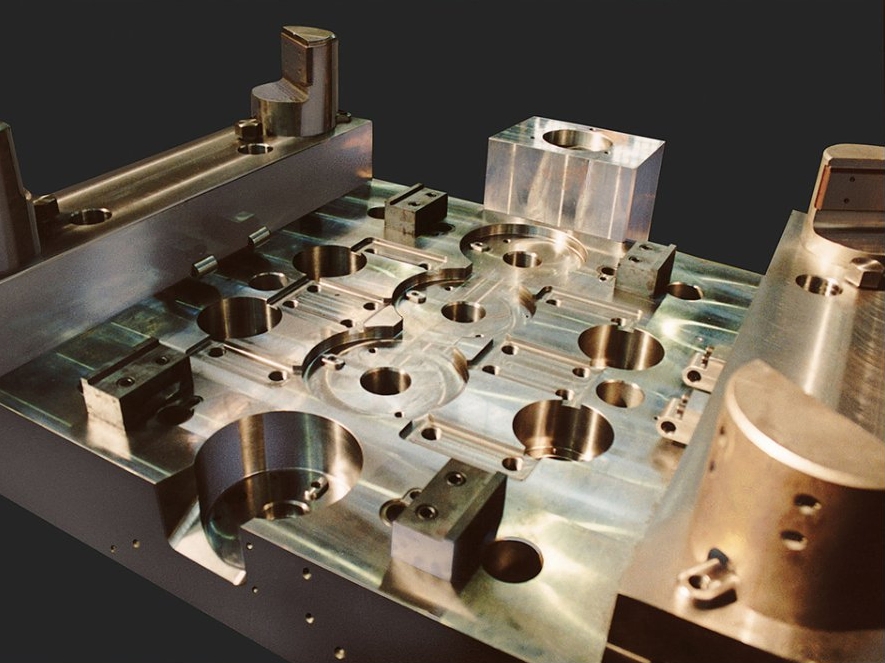

Choosing the right steel and heat treatment defines the life of Precision dies. Material and process choices affect wear, toughness, distortion, and maintenance cycles. Therefore, engineers must match steel chemistry, thermal cycles, and surface treatments to the application. I give a practical, engineering-focused guide. This guide explains which alloy to choose, how to perform heat treatment, and which surface treatments or post-treatments can extend the life of the precision die.

Match the steel family to the loading and wear modes

First, identify the dominant load. Does the die cut, blank, form, or stamp at high temperature? For heavy wear and abrasion, high-carbon, high-chromium cold-work steels, such as D2, are commonly used. For hot-forming or die-casting tooling, hot-work steels such as H13 are the most suitable. Tools prone to impact and shock, shock-resistant grades like S7 provide toughness. Match the steel to the load, as the wrong family can deliver poor life, regardless of heat treatment. Industry datasheets and supplier guides summarise recommended applications for each grade.

Understand the trade-off between hardness and toughness

Hardness improves wear resistance. However, excessive hardness compromises toughness and increases the risk of cracking. For example, D2 can reach a hardness of ~60–62 HRC after hardening, which provides excellent edge retention. Yet, D2 can be brittle if not tempered correctly. Conversely, H13 offers good toughness at 45–52 HRC after tempering, which suits hot-work tools that see thermal cycling. Therefore, balance target hardness with the application: choose a higher hardness for abrasive wear and a moderate hardness for shock or thermal stress.

Heat treatment basics: quench, temper, and dimensional control

Proper heat treatment starts with controlled austenitizing and ends with tempering. Quenching creates hard martensite, while tempering reduces brittleness and stabilizes dimensions. For many tool steels, immediate tempering after quench prevents cracking and converts retained austenite. Additionally, tempering cycles determine the final hardness and retained stress. Always follow the supplier’s heat-treatment curves and incorporate stress-relief steps between rough and finish machining to minimize distortion. Reliable vendor guides provide temperatures and hold times for common grades.

Surface engineering nitriding, carburising, and coating

Surface treatments give a hard skin while preserving a more rigid core. Nitriding forms a hard nitride layer at lower temperatures. It enhances wear and fatigue resistance without significant core changes, making it ideal for tooling that requires a thin, hard surface. In contrast, carburizing produces a deeper, carbon-enriched case for parts that require a thick, rigid surface layer. For many die applications, thin, hard coatings applied by PVD, such as TiAlN, significantly reduce abrasive wear and extend intervals between regrinds. Combine surface treatments with base alloy choice for best results.

Use shot peening and residual-compression methods to fight fatigue

Fatigue often kills at corners and holes. Shot peening induces compressive residual stresses in the surface, which delays crack initiation. Additionally, proprietary surface modifications can significantly mitigate stress-corrosion cracking and dramatically extend the life of components in corrosive or cyclic load environments. For stamping and high-cycle tools, shot peening, combined with appropriate heat treatment, has shown measurable life gains. Therefore, include peening in the arsenal, especially where cyclic fatigue limits the life of components.

Cryogenic processing and PM steels

Cryogenic treatment aims to transform retained austenite to martensite and refine carbide distribution. Studies have reported improved wear resistance and stability after deep cryogenic cycles, particularly in tool steels that are subject to abrasive wear. Meanwhile, powder-metallurgy (PM) tool steels offer uniform carbide distribution and superior toughness. PM grades often outperform conventional cast/forged steels in life-critical dies. Thus, consider cryo-treatment for existing dies and PM steels when designing new high-performance tools.

Practical process controls to minimise distortion and rework

Control matters. Preheat uniformly before hardening and cool with consistent quench media to avoid cracking. Machine with recommended allowances; perform intermediate stress-relief cycles before finishing machining. Additionally, measure and log the dimensional change after heat treatment to refine machining allowances. Use statistical process control for heat-treat batches. These practical steps minimize surprises and reduce costly rework. Supplier tech notes explain typical dimensional changes and recommended machining allowances for specific steels.

Design, surface finish, and maintenance checklist for Precision dies

Design for longevity. Use radii at stress points, avoid sharp internal corners, and specify fillets that reduce local stress. Then, select a steel that matches the wear and shock requirements, and define a heat-treatment recipe that balances hardness and toughness. Next, add a surface treatment, such as nitriding, carburizing, PVD coating, or shot peening, as required. Finally, document inspection intervals, regrind limits, and remanufacture plans should be established. Doing this makes Precision dies last longer, reduces downtime, and cuts total tool cost. For authoritative guidelines, consult supplier heat-treatment datasheets and peer-reviewed studies when specifying materials and processes.