Changeovers and setups eat productive time. For stamping, machining, and assembly shops, lost time hurts delivery and margin. Precision jigs reduce non-value work. They also standardise setup steps. Consequently, shops shorten changeovers, boost uptime, and increase throughput. I’ll walk you through proven best practices, practical strategies, and real-world evidence that you can take action this week.

Start with process mapping and SMED principles

First, map out your current setup step by step. Then, separate the internal from the external steps. In other words, move as many tasks as possible off-press or off-machine. This is the core of SMED (Single-Minute Exchange of Die). In practice, SMED helps teams find hidden waste and convert tasks into external work. When shops apply SMED rigorously, they often significantly reduce changeover time. For background and method, see SMED resources and case guidance.

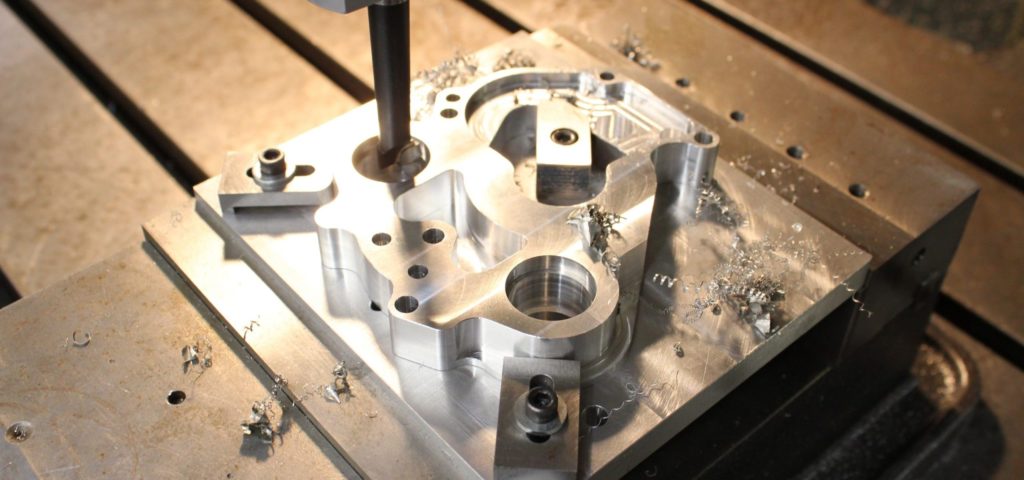

Design jigs for repeatability and quick location

The precision jig must automatically locate parts. Therefore, use kinematic locating points and hardened datum surfaces. Next, design clamps that lock with one motion. Also, use poka-yoke features to prevent incorrect placement. As a result, operators spend far less time measuring or adjusting. Moreover, a consistent location reduces part variation and scrap. Good jig design is the fastest route to repeatable first-offs.

Adopt quick-change hardware and standard interfaces

Standardise interfaces across dies and fixtures. For example, apply a uniform clamping plate or quick-lock pin system so dies mate instantly. In effect, a standard interface removes alignment guesswork. Additionally, utilise quick-disconnect utilities for air, coolant, and sensors. That way, teams can convert internal steps to external ones, thereby speeding up the changeover process. Industry examples demonstrate that quick-change systems can reduce die setup time from hours to minutes.

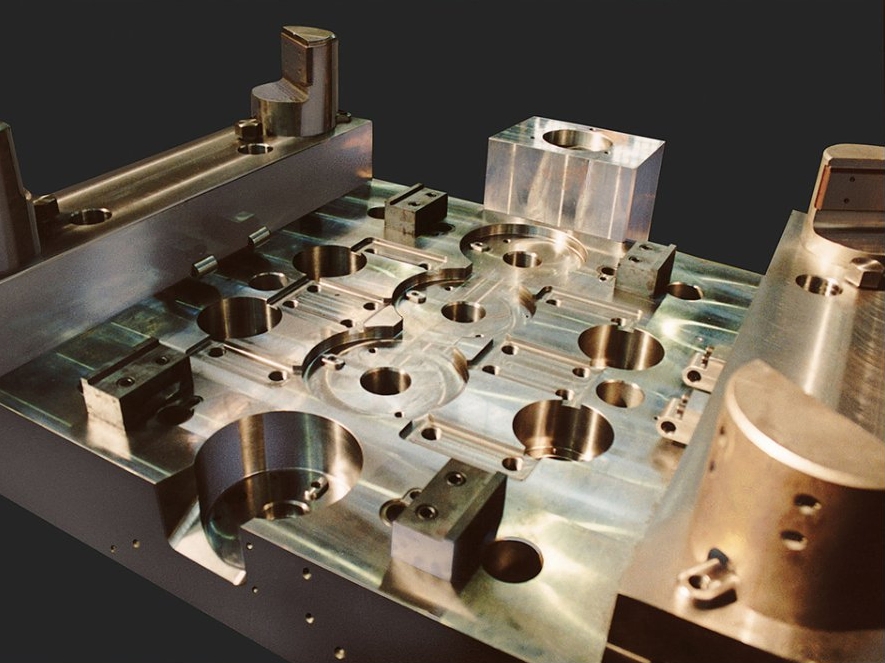

Use modular, adjustable jigs to handle families of parts

Instead of building one-off fixtures, design modular jigs. Use interchangeable sub-fixtures, adjustable stops, and indexed mounting patterns. Consequently, you reduce the number of complete changeovers when switching similar parts. Additionally, modularity reduces tooling costs and storage space requirements. Therefore, manufacturers achieve both flexibility and consistency with fewer bespoke fixtures.

Integrate sensors, visual cues, and SOPs for standard work

Combine physical jig design with clear standard work. For example, add visual alignment marks and torque-limited fasteners. Also, include sensors that confirm correct clamp engagement. Then, link these signals to a visual board or PLC to confirm readiness. This integrated approach prevents missed steps and speeds operator confidence. Importantly, standard work makes changeovers predictable and repeatable across different operators.

Train teams and run focused SMED events

Training matters. Run focused SMED workshops with cross-functional teams. During the event, take each step, test alternative methods, and document the new sequence. In many cases, firms reduce setup times by 30–50% after a single SMED cycle. Furthermore, continuous kaizen efforts following the event capture incremental gains. For real-world evidence and structured steps, SMED case studies and academic papers provide tested templates.

Leverage mechanical aids, motion control, and die handling

Don’t rely solely on human muscle. Use hoists, pre-rollers, and guided trolleys to position heavy dies. Moreover, implement motorised motion control for fine alignment where appropriate. In several press-floor case studies, motion control and guided handling reduced die change time from approximately two hours to ten minutes. Consequently, mechanical aids not only speed changeovers but also improve safety and reduce damage risk.

Action checklist and why Precision jigs matter

Finally, act with a practical checklist. First, map your current changeover and apply SMED to separate external tasks. Second, standardise interfaces and adopt quick-change hardware. Third, design jigs with kinematic locators, single-motion clamps, and poka-yoke features to ensure accuracy and prevent errors. Fourth, choose modular elements to handle part families. Fifth, add sensors and visual cues tied to SOPs. Sixth, run SMED workshops and train operators. Seventh, invest in mechanical handling and motion control for heavy tooling. Together, these steps cut setup time, improve first-pass yield, and lift throughput. In short, well-engineered Precision jigs transform changeovers from a bottleneck into a competitive advantage.