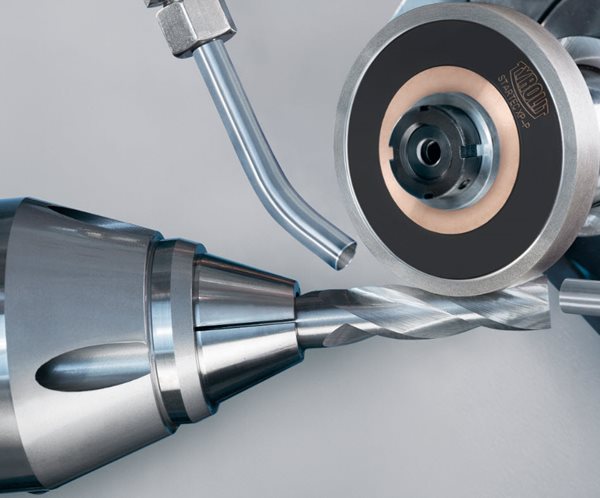

Precision grinding tools are essential in modern manufacturing. They provide accurate, consistent surface finishing, which reduces material waste. By controlling tolerances tightly, these tools prevent overcutting or scrapping. Industries such as automotive, aerospace, and electronics rely on them for cost efficiency. Moreover, precision grinding improves part quality while extending the lifespan of equipment. The combination of accuracy and reliability makes these tools a key factor in sustainable production.

Enhanced Accuracy and Consistency

One of the main advantages of precision grinding tools is their accuracy. Tight tolerances ensure components meet specifications without unnecessary material removal. This consistency reduces the need for rework and lowers scrap rates. Additionally, precision tools maintain surface integrity, preventing defects and improving performance. By delivering predictable results, manufacturers can plan production more efficiently. High-quality precision grinding also allows integration with stamping dies, ensuring consistent dimensions across complex parts.

Reducing Over-Machining and Scrap

Over-machining is a common source of material waste. A Precision grinding tool minimises waste by removing only the necessary amount of material, ensuring optimal efficiency. Unlike traditional machining, these tools achieve fine cuts and smooth finishes. As a result, less raw material is discarded, which lowers overall costs. Furthermore, reduced scrap contributes to sustainability goals. Manufacturers save resources, cut expenses, and maintain a smaller environmental footprint by using precision grinding instead of rough machining methods.

Improved Surface Finish and Quality

Surface finish impacts both functionality and aesthetics. Precision grinding tools achieve smooth, even surfaces with minimal defects. This quality reduces the risk of rejected parts and improves assembly efficiency. For high-performance components, such as those used in aerospace or automotive applications, a precise surface finish ensures a proper fit and reduces wear. Consequently, manufacturers avoid wasting materials on defective components. Moreover, combining precision tools with stamping dies enhances surface uniformity, further reducing material waste.

Optimising Tool Life and Efficiency

Tool longevity is another critical factor. Precision grinding tools are designed to maintain their sharpness and accuracy over extended periods of time. A longer tool life means fewer replacements, which reduces downtime and associated waste. Proper tool maintenance and selection prevent chipping or uneven wear. Consequently, manufacturers maximise efficiency while minimising the number of worn-out tools discarded. Integrating precision tools into regular maintenance schedules also ensures consistent production quality.

Integration with Automation Systems

Modern production often uses automated grinding systems. Precision grinding tools fit seamlessly with CNC machines and robotic cells. Automation ensures repeatable cuts with minimal human error. This precision lowers material loss during high-volume production runs. Moreover, automated systems can monitor tool wear in real time, alerting operators before defects occur. Integrating stamping dies with automated grinding further enhances accuracy and reduces material waste consistently across large batches.

Material-Specific Grinding Strategies

Different materials respond differently to grinding. Precision tools enable manufacturers to adjust speed, feed, and pressure according to the material type. Metals, composites, and alloys require unique approaches to prevent excessive wear or damage. By fine-tuning grinding parameters, manufacturers reduce scrap and improve yield. Using the right combination of precision tools and stamping dies ensures each material is handled optimally. Consequently, waste is minimised without sacrificing quality or performance.

Cost Savings and Sustainable Production

Reducing material waste directly impacts cost savings. Less scrap means lower raw material expenses and fewer disposal requirements. Precision grinding tools help manufacturers achieve sustainable production by maximising yield and efficiency. Additionally, they reduce energy consumption compared to rough machining, as less material is removed per operation. Companies that implement precision tools effectively can achieve both financial and environmental benefits. This approach makes production more efficient, competitive, and eco-friendly.

Precision Grinding Tools and Material Waste Reduction

Precision Grinding Tools play a crucial role in reducing material waste. They provide enhanced accuracy, consistent surface quality, and optimised tool life. By integrating precision tools with stamping dies and automated systems, manufacturers minimise scrap and over-machining. Material-specific strategies further improve yield while maintaining performance standards. These tools not only save costs but also support sustainable production practices.