If you are making thin-sheet parts for consumer electronics, you know the job is more finicky than it looks. Precision Machining helps ensure each part meets tight tolerances and high-quality standards. Pick the right alloy, cut it clean, and manage springback during every bend. Get your tooling and fixtures locked down so parts fit together without fuss. Nail surface preparation early to avoid rework after finishing. Prototype fast, record bend tables, and add targeted inspection steps to catch drift. Engineers, buyers, and product teams will find these practical Precision Machining checks cut scrap and speed time to market.

Material selection and design for manufacturability

Choose the correct alloy and temper early in the process to ensure reliable Precision Machining results. Common choices include aluminium for lightness and stainless steel for strength. Each material affects tooling, bending radii, and springback behaviour. Therefore, specify thickness and temper precisely on drawings. Also, design with gradual radii and bend reliefs to reduce cracking. Additionally, avoid sharp internal corners that concentrate stress and cause failures. Next, consider coatings and finishes during design to prevent rework. Furthermore, perform basic forming simulations or quick hand trials to catch obvious issues early. Additionally, validate prototypes and update drawings before production starts.

Cutting and blanking methods

Select cutting methods based on volume and the complexity of features. For high volume, turret punching or progressive dies deliver speed and low unit cost. Conversely, laser cutting or waterjet suits complex contours and lower volumes. However, laser heat can alter edge metallurgy, so control parameters must be carefully selected. Additionally, optimize nesting to reduce scrap and material costs. Also, inspect burr levels and edge squareness immediately after cutting. Then adjust cutting speeds or die clearances to improve edge finish and hole accuracy. Additionally, verify the temperature and thickness of the material as stated on the certificates. Furthermore, simulate forming now quickly.

Bending, forming, and springback control

Control bends with precision press brakes and reliable back gauges. Use progressive forming or multi-step bending for tight geometries to achieve optimal results. Also, select tooling that matches the material and bend radius to minimize springback. Therefore, compensate for springback by adjusting tool paths or using slight overbend methods. Moreover, perform hemming and flanging for exposed edges to improve strength and appearance. In addition, apply clamps and soft jaws to prevent imprint marks on visible surfaces. Next, record the tool settings and bend angles to ensure repeatability. Furthermore, simulate forming now to reduce failures quickly.

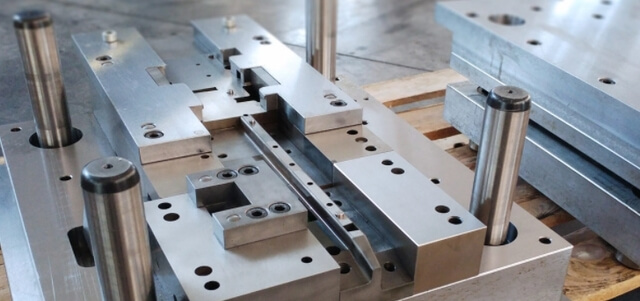

Tooling, fixtures, and process stability

Invest in durable tooling and precision fixtures to reduce variation. Effective tools reduce scrap and significantly extend uptime. Therefore, choose coated or carbide tooling for abrasive alloys. Also design quick-change fixtures to reduce setup time and improve repeatability. Implement poka-yoke features to prevent misalignment during high-speed runs. Moreover, adopt SPC and maintain control charts for key dimensions. Then schedule preventative maintenance and tool replacement based on measured wear. Additionally, track cycle times, rejects, and tool life to inform continuous improvement—also, document bend tables and tool settings.

Surface finishes and secondary processes

Plan finishing early to avoid costly rework later. Common finishes include anodizing, plating, brushing, and powder coating. Each finish needs specific pre-treatment and handling. Therefore, avoid deep scratches before coating and specify masking for contact areas to prevent damage. Additionally, verify coating thickness and adhesion with tests during first-article inspection. Also, factor in post-forming operations, such as tumbling or deburring, to improve edge quality and appearance. Next, coordinate finish suppliers and schedule to prevent delays on the critical path. Furthermore, ensure paint or coating tolerances match assembly and thermal requirements. Also, document bend tables and tool settings for finishing compatibility.

Inspection, testing, and traceability

Develop a comprehensive inspection plan that incorporates first-article checks and ongoing sampling—Utilise CMMs for complex geometry and optical comparators for flatness and profile measurements. Also, verify hole sizes, thread engagement, and surface roughness with calibrated gauges. Therefore, set AQL levels and lot sampling procedures that match product risk. Additionally, keep traceable material certificates and process logs for each batch. Then analyze trends using SPC to catch drift before parts fail. Moreover, perform functional tests on assembled units to validate real-world fit and durability. Additionally, review tool wear rates and replace before tolerances drift.

Assembly, tolerances, and integration

Design parts with assembly in mind to reduce rework on the line. Specify tolerances that align with downstream processes and accommodate stack-up. If parts mate to PCBs or enclosures, verify the stack-up with actual components early. Additionally, consider the accessibility of fasteners and the placement of slots to facilitate ease of assembly and maintenance. For press-fit features, define insertion forces and test with production fixtures.

Additionally, plan for thermal expansion during operation and provide clearance where necessary. Next, assemble prototype units to validate fit and function before committing to large-scale production runs. Next, confirm.

Conclusion and recommendations for Precision Machining

In practice, successful thin sheet parts come from good design, the right materials, and tight process control. Start with DFM reviews and quick prototypes to catch problems early. Standardise tooling, fixtures, and inspection routines to maintain consistent quality across runs. Prioritize finishes and assembly tests to ensure the final product meets expectations. Utilize SPC and regular maintenance to minimize variation and prevent costly downtime. Collaborate with suppliers who provide traceability, prompt support, and a commitment to ongoing improvement. Additionally, maintain a concise acceptance checklist for incoming batches and conduct a basic inspection on samples. When you follow these steps, your Precision Machining outcomes improve and your time to market shortens.