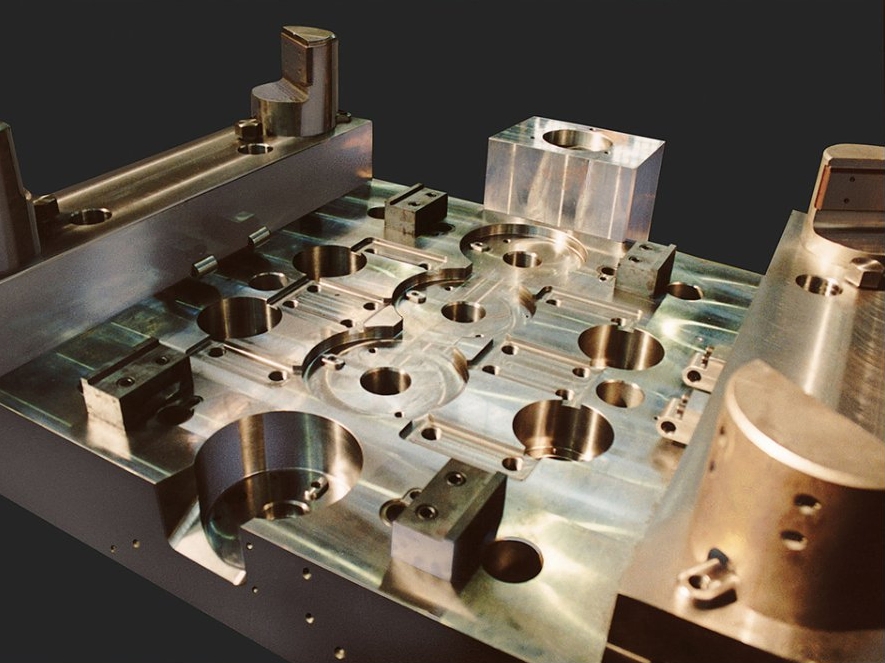

The advent of 3D Printing has transformed industries across the board, including the metal die industry. Traditionally, metal mold manufacturing involves time-consuming processes, including casting, forging, and machining. While effective, these methods often require significant time, effort, and cost to produce high-precision molds. 3D Printing can accelerate Prototyping, reduce costs, and increase design flexibility. As 3D Printing continues to advance, its impact on the metal mold industry is becoming increasingly apparent. Will the development of 3D printing technology subvert the traditional metal mold industry or become a catalyst for improving efficiency? This is a question worth exploring.

Faster Prototyping with 3D Printing

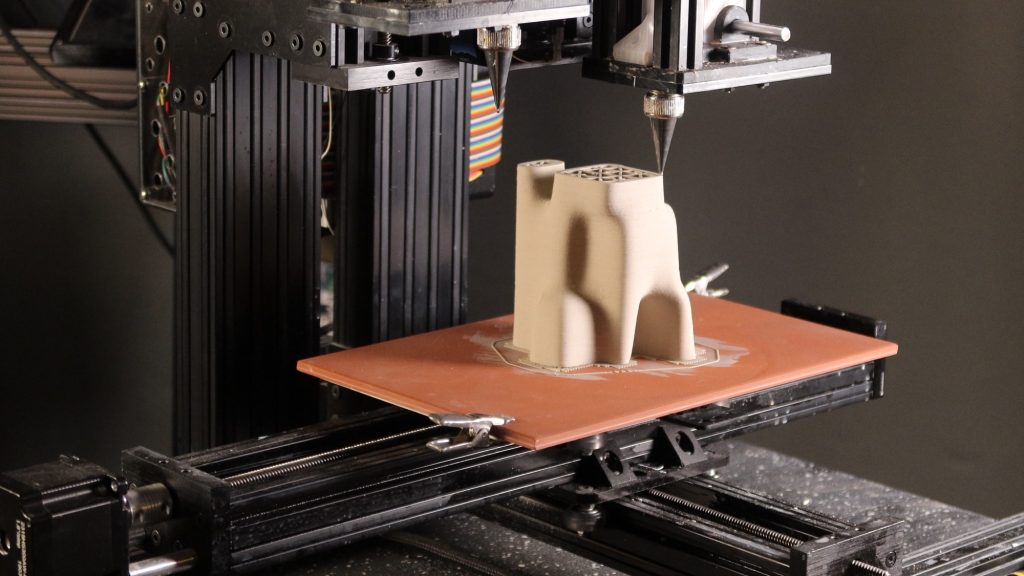

One of the biggest challenges in the metal die industry has always been the time required for Prototyping. In traditional methods, creating a prototype can take weeks or even months, delaying production timelines. However, with 3D Printing, prototypes can be made in a matter of days.

This acceleration in Prototyping means that manufacturers can test and refine designs much quickly. Faster iteration enables faster feedback, ultimately leading to improved metal die designs. Whether it’s for a stamping die or another die, 3D Printing allows for rapid modifications, reducing lead times and increasing overall productivity.

Cost Reduction through Additive Manufacturing

Cost is a major factor in the manufacturing of metal die components. Traditional methods require significant material costs and labor to create complex geometries. With 3D Printing, manufacturers can build dies layer by layer, which reduces the amount of material wasted. This process, known as additive manufacturing, enables manufacturers to create highly complex shapes with less material and less waste, cutting overall production costs.

Furthermore, 3D Printing can reduce labor costs associated with mold-making, tool changes, and manual adjustments. With faster lead times and less material waste, the cost of producing metal stamping dies and other tools can be significantly reduced, making production more cost-effective and competitive.

Design Flexibility with 3D Printing

One of the most significant advantages of metal die production using 3D Printing is the flexibility in design. Traditional die-making processes have limitations when it comes to creating complex, intricate shapes. However, with 3D Printing, manufacturers can design dies with highly detailed geometries that would otherwise be impossible to produce with traditional methods.

This design flexibility is beneficial for industries that require highly customized metal stamping dies. Whether it’s a die for a unique part, a custom feature, or an unusual geometry, 3D Printing can easily accommodate these requests. This capability is driving innovation in die design and enabling manufacturers to push the boundaries of what is possible in metal die production.

Improved Efficiency and Speed in Manufacturing

Efficiency is crucial in the metal die industry, where delays can significantly impact overall production schedules. Traditional manufacturing methods, though reliable, can be slow. Cutting, molding, and adjusting dies can be time-consuming, resulting in prolonged production cycles. 3D Printing eliminates much of the time-consuming tooling and adjustments.

By printing the die components directly, manufacturers can reduce setup times and streamline production. This increased efficiency is not only beneficial for large manufacturers but also for smaller companies or startups seeking to produce high-quality metal stamping dies without incurring costly tooling investments. As a result, companies can meet tight deadlines and fulfill customer demands more quickly.

Customization and On-Demand Production

Another compelling advantage of 3D Printing in the metal die industry is the ability to produce custom dies on demand. Instead of maintaining a large inventory of different die sizes and types, manufacturers can now make customized dies as needed. This flexibility proves especially useful in industries where companies frequently adjust product specifications or require unique, one-off dies for special projects.

On-demand production reduces the need for significant investments in tooling and inventory. This means manufacturers can be more agile, responding to customer needs in real-time and avoiding the costs associated with keeping an extensive die stock. Custom metal stamping dies can be designed and printed to meet specific requirements, reducing waste and ensuring precise fits for unique applications.

Enhanced Durability and Performance of Dies

The materials used in 3D Printing have improved significantly over the years, allowing for the production of metal die components that are not only lightweight but also durable and performance-optimized. With advanced materials such as metal alloys and composite metals, 3D Printing can create metal stamping dies that have improved wear resistance, high heat tolerance, and enhanced performance characteristics.

These performance improvements can extend the lifespan of dies, reducing the frequency of replacements and repairs. In industries where downtime is costly, having durable and high-performing dies is a significant advantage. Additionally, 3D Printing allows manufacturers to incorporate design elements that improve cooling efficiency or reduce friction, further enhancing die performance and longevity.

Sustainability in Die Manufacturing

Sustainability has become a key concern in all manufacturing sectors, and the metal dies industry is no exception. Traditional die production methods often generate significant waste due to material removal processes, and the energy consumption can be high. However, 3D Printing can reduce waste by using only the material necessary for the component.

Additionally, 3D Printing uses less energy compared to traditional manufacturing techniques. The process adds material only where needed, reducing waste. For industries looking to adopt more sustainable practices, 3D Printing offers an attractive solution for producing metal stamping dies and other components in an environmentally friendly way.

The Future of Metal Dies Production with 3D Printing

Looking ahead, 3D Printing is poised to revolutionize the metal die industry even further. As technology advances, we can expect to see even more efficient, precise, and cost-effective solutions for die production. The integration of artificial intelligence (AI) and machine learning with 3D Printing could lead to fully automated, self-optimizing production lines for metal stamping dies.

In the coming years, more industries will adopt 3D Printing for die manufacturing, driven by the ongoing demand for faster, cheaper, and more complex solutions. As companies continue to embrace this technology, it will unlock new opportunities for innovation, efficiency, and sustainability in the production process.

The Long-Term Impact of 3D Printing on the Metal Die Industry

From faster prototyping and lower costs to greater design flexibility and on-demand production, 3D Printing is transforming the way metal stamping dies and other die components are produced. As the technology continues to advance, it is likely to become the standard for mold production, offering further advantages in performance, efficiency, and sustainability.