Reducing die costs without sacrificing performance sounds impossible. Many manufacturers assume that saving money means sacrificing durability or precision, but is that the case? Many manufacturers assume saving money means sacrificing durability or precision, but that’s not the case. In fact, with the right approach, every penny saved in design, materials, and artistry can add up without sacrificing quality. Want to know how to reduce costs while maintaining a strong, precise, and durable die? Let me explain.

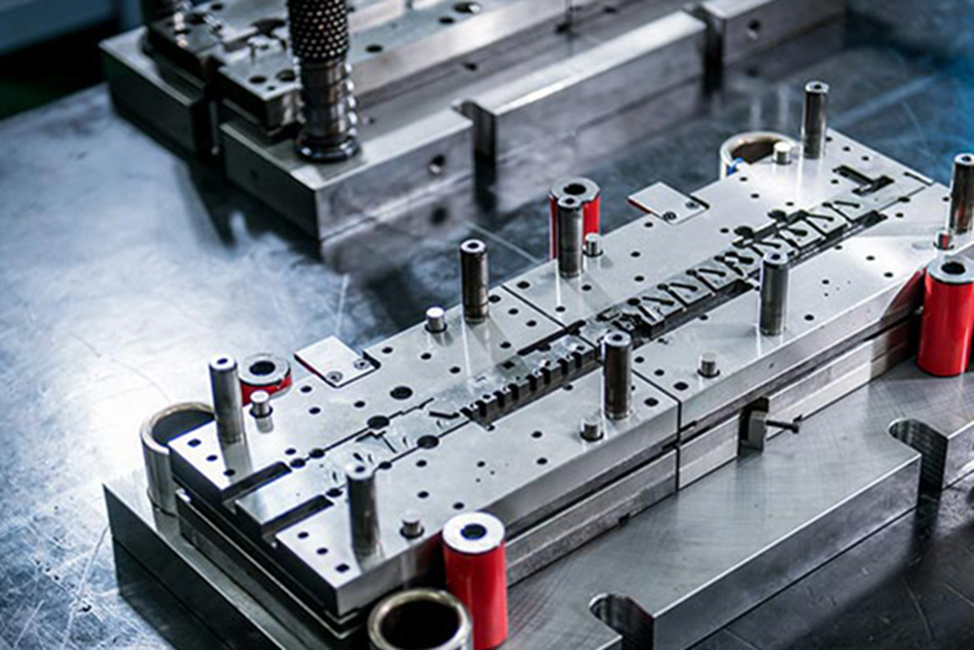

Optimize Design for Efficiency

Complex dies drive costs up dramatically. Simplifying designs by eliminating unnecessary features significantly reduces machining time and material waste. Functional yet straightforward designs cut expenses while maintaining required strength and precision. Use simulation tools to test die performance before cutting metal. Early validation prevents expensive redesigns and project delays. Consider modular designs when possible. Interchangeable inserts reduce the need for a full die replacement. Progressive die setups, in particular, allow for flexibility in different forming stages without excessively increasing tool complexity or costs.

Choose Materials Wisely

High-grade steel offers extraordinary durability but isn’t always the most cost-effective choice for all applications. Match steel grade carefully to specific application needs. Over-engineering adds cost without meaningful benefits. For less demanding parts, consider cost-efficient alternatives that do not compromise dies performance. Surface treatments can extend tool life without the need for upgrading to premium alloys. Coatings such as TiN or CrN enhance wear resistance. The key is balancing material strength and hardness with the projected production volume and operating conditions.

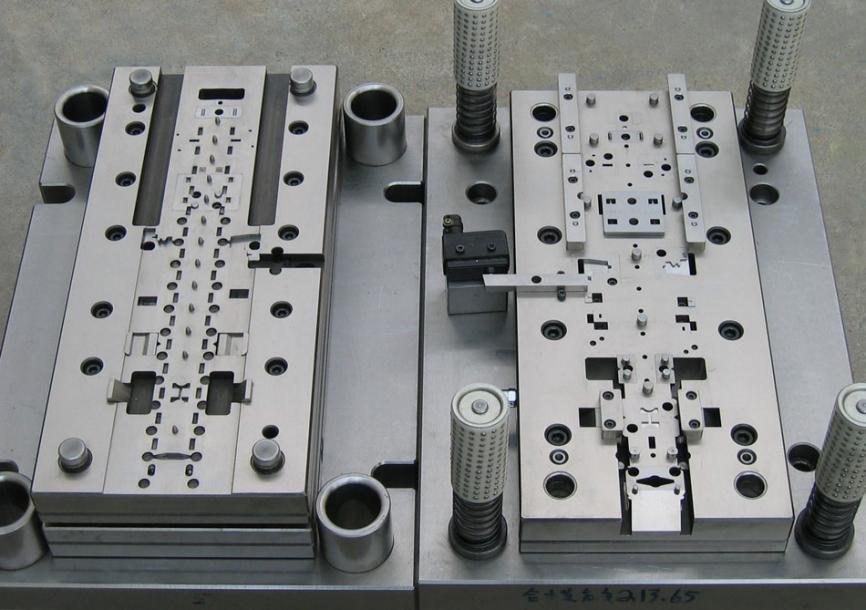

Leverage Standard Components

Custom components increase both cost and production time. Whenever possible, use standard parts in stamping dies. Standardized guide pins, bushings, and fasteners reduce manufacturing complexity and cost. This approach also speeds up maintenance and replacement, minimizing downtime. Buying standard components in bulk further reduces expenses. This method supports consistent quality while keeping expenses under control. Focus custom work only on critical, high-impact sections of the die where standard parts fail to meet requirements.

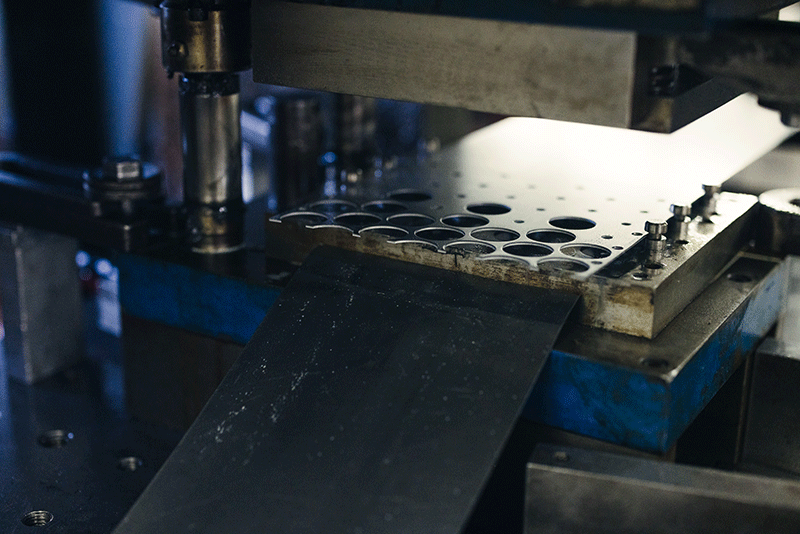

Improve Process Efficiency

Production efficiency has a significant impact on overall die costs. Poor process planning causes excessive tool wear and unplanned downtime. Regularly review press speed, lubrication quality, and die alignment to optimize performance. Minor operational adjustments can extend die life and lower repair and replacement expenses. Progressive die systems streamline the forming process into a single, continuous operation. This reduces handling time and material waste. Efficient processes lower total production cost while preserving or even improving dies performance.

Work with Experienced Suppliers

Expert suppliers add value beyond just materials and machining. They help optimize die design and recommend cost-saving alternatives based on real-world experience. A knowledgeable partner ensures proper heat treatment, assembly, and rigorous testing to guarantee optimal performance. These factors heavily influence tool longevity and dimensional precision. Collaborate early during the design stage to avoid costly mistakes later. Experienced suppliers understand the demands of stamping dies and how to meet them cost-effectively while maintaining die performance.

Preventive Maintenance Matters

Skipping maintenance to save money is a false economy. It leads to premature tool failure and expensive production downtime. Scheduled inspections catch wear and damage before they escalate into problems. Replace inserts and sharpen cutting edges at recommended intervals. Use predictive maintenance tools where possible. Sensors and digital monitoring track the die condition and performance over time. This proactive approach prevents unexpected failures and keeps production smooth, ensuring long-term dies performance and cost savings.

Use Technology for Cost Reduction

Simulation, CAD, and CAM tools reduce design and manufacturing errors. Virtual testing predicts weak points before physical production starts. This reduces rework and scrap, saving both time and materials. Automation in machining and assembly also cuts labor costs. CNC precision enhances consistency, reducing the need for adjustments during die setup and maintenance. These technology investments often pay for themselves through improved efficiency and lower waste. Combined with proper maintenance, they help keep dies’ performance high without overspending.

Smart Ways to Cut Die Costs Without Sacrificing Performance

Saving costs without compromising dies performance requires better design, appropriate materials, and a comprehensive maintenance plan. By simplifying the design, standardizing components, streamlining processes, and digitalizing the mold, you can achieve dies that offer the best balance of performance and price.