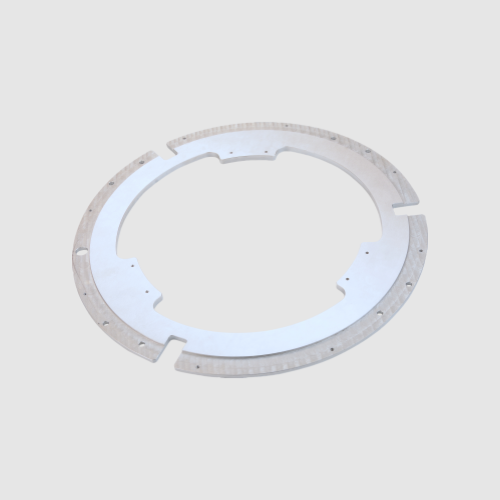

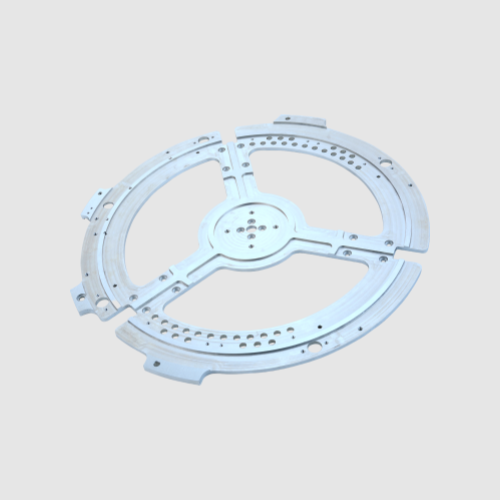

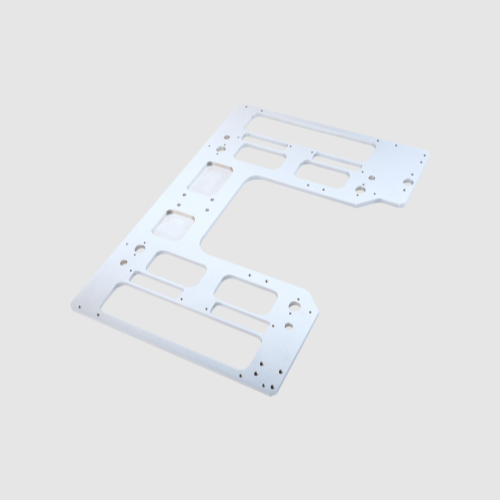

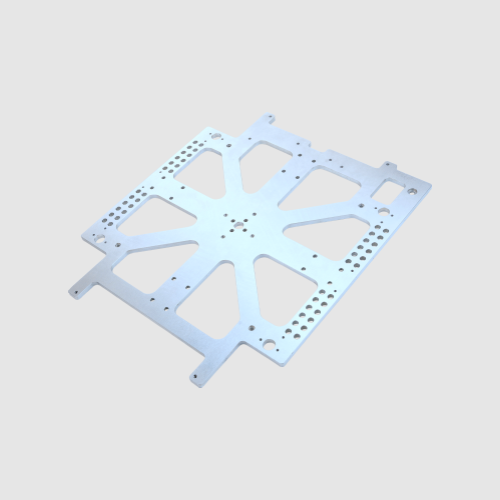

AUTOMATION PARTS AND JIGS

- Home

- product

- AUTOMATION PARTS AND JIGS

AUTOMATION PARTS AND JIGS

Typical Data Sheet (General Specification)

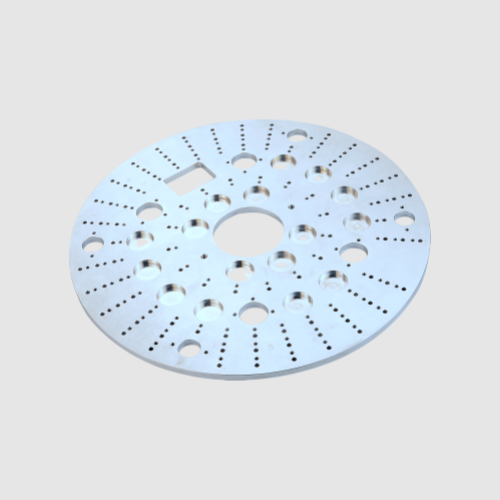

| Category | Example Parts | Features |

|---|---|---|

| Transmission Components | Gears, Couplings, Timing Belts | High torque resistance, smooth transmission |

| Linear Motion Systems | Ball Screws, Guide Rails, Linear Shafts | Low vibration, high positioning accuracy |

| Actuation Components | Lifting Units, Mechanical Arms, Slides | Fast response, precision actuation |

| Structural Components | Base Frames, Aluminum Profiles | Modular, corrosion-resistant, easy assembly |

| Custom Tooling & Jigs | Assembly Jigs, Inspection Fixtures, Welding Jigs | Tailored for specific production needs |

Product Description

Our Automation Parts and Jigs are engineered to optimize motion control, assembly, testing, and inspection across high-speed automation lines. From precision gears and ball screws to custom jigs and fixtures, every component is designed for accuracy, repeatability, and long-term reliability.

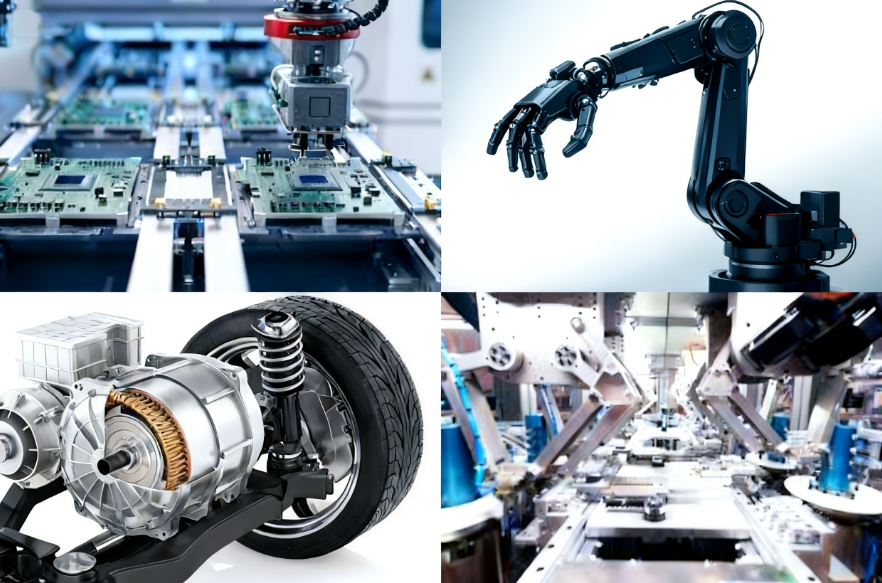

Built with stainless steel, alloy steel, aluminum, or engineered composites, our solutions are suitable for industries such as automotive, electronics, aerospace, packaging, robotics, and industrial automation.

Whether you need standard automation-ready components or custom-engineered tooling and jigs, our team supports OEM and ODM projects from design to delivery, ensuring seamless integration into your production system.

Key Features and Advantages

High Accuracy and Repeatability: Maintain stable precision for CNC machining, inspection, and robotic assembly.

Durable Materials: Made from hardened alloys, stainless steel, and engineered plastics for extended service life.

Custom Engineering: Tailored jigs and automation components designed for unique manufacturing challenges.

Seamless Integration: Plug-and-play with servo motors, robotic arms, conveyors, and PLC systems.

Efficiency Boost: Reduce setup time and production downtime with modular, easy-to-install designs.

Wide Application Range: Ideal for stamping, assembly, testing, packaging, and automated handling systems.

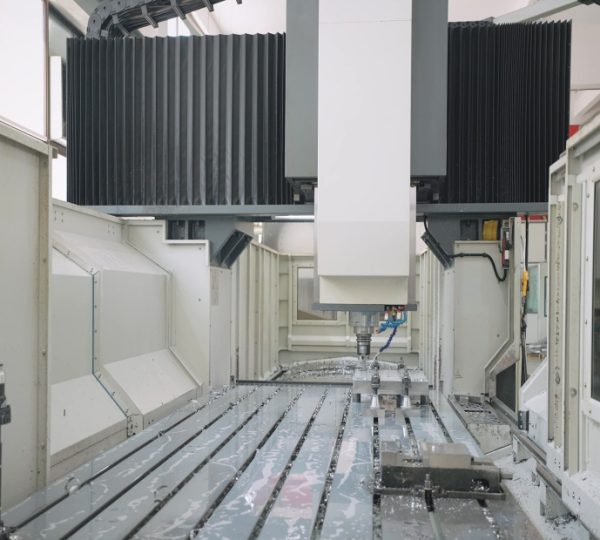

Technical & Equipment Advantages

Advanced CNC Machining Centers: Multi-axis milling, turning, and EDM machines for tight tolerances and complex geometries.

Precision Grinding & Jig Fabrication: High-accuracy grinding and fixture assembly to ensure stability and repeatability.

Comprehensive CAD/CAM Capabilities: Full 2D/3D modeling, simulation, and rapid prototyping for custom automation solutions.

High-Performance Materials: Stainless steel, alloy steel, aluminum, and engineering plastics selected for strength and durability.

Surface Treatment Expertise: Heat treatment, coating, and anodizing processes to maximize wear resistance and longevity.

Strict Quality Control: ISO-standard inspection, CMM measurement, and performance testing for every part and jig.

Scalable Production Capacity: From prototype runs to full-volume manufacturing with flexible lead times.

Global Integration Support: Engineering guidance and on-site assistance for seamless adoption into production lines.

Common Applications

Automotive: Engine assembly jigs, chassis alignment, precision machining components.

Electronics: PCB assembly fixtures, semiconductor handling, inspection systems.

Aerospace: High-precision inspection jigs, turbine part positioning, quality testing.

Packaging: Conveyor automation, palletizing jigs, labeling machine parts.

Robotics / AGVs: Motion systems, actuator parts, robotic grippers, fixture setups.

General Manufacturing: High-speed production lines, automated assembly, precision handling.

Why Choose Us

We provide full customization with OEM and ODM solutions tailored to your production.

Our advanced CNC machining guarantees tight tolerances and consistent accuracy.

We help you improve efficiency by reducing waste and shortening lead times.

Our solutions cover everything from simple jigs to complex automation assemblies.

We ensure durability and reliability to support demanding global industries.

FAQs about Automation parts and jigs

Automation parts drive motion and process control, while jigs and fixtures ensure precise positioning and repeatability during manufacturing.

Yes, we provide CAD/CAM-based design, prototyping, and full-scale production.

Automotive, electronics, aerospace, packaging, and robotics sectors rely heavily on our automation parts and jigs.

Absolutely. Our products are designed for seamless plug-and-play with standard industrial systems.

Yes, we offer engineering consultation and on-site guidance to ensure smooth implementation.

Need customization, please contact us

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN