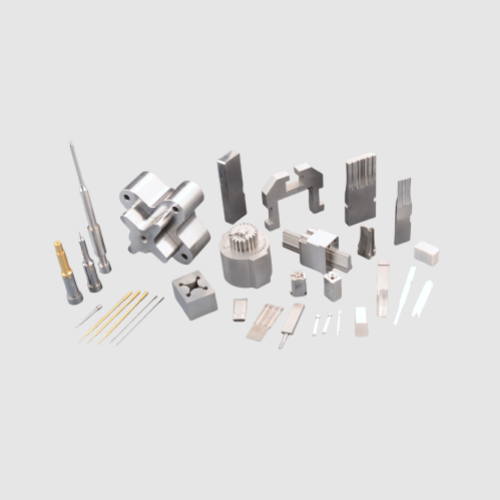

PRECISION PARTS

- Home

- product

- PRECISION PARTS

PRECISION PARTS

Typical Data Sheet (General Specification)

| Parameter | Value / Option |

|---|---|

| Tolerances | Up to ±0.002 mm |

| Manufacturing Process | CNC Milling (3-, 4-, 5-axis), CNC Turning, Swiss Lathe |

| Material Options | Steel, Aluminum, Titanium, Copper, Plastics, Composites |

| Surface Finish | Polishing, Anodizing, Plating, Coating |

| Production Capacity | Prototype to mass production |

| Industry Standards | ISO-compliant inspection & testing |

Product Description

Chaoyang precision parts are high-accuracy components crafted from metal, plastic, or composite materials to meet extremely tight tolerances. These parts are critical in industries where reliability and safety are paramount, including aerospace, defense, and automotive. Utilizing advanced CNC machining techniques, including milling and turning, our precision parts ensure superior dimensional accuracy, durability, and repeatability.

Key Features and Advantages

Ultra-tight tolerances up to ±0.002 mm for critical applications

Manufactured with CNC milling and turning, including 3-axis, 4-axis, and 5-axis machining

Wide material selection including steel alloys, aluminum, titanium, and composites

Capability to produce intricate and thin-walled designs with Swiss lathe technology

Surface finishes and coatings available for enhanced wear resistance and performance

Ideal for prototypes, small-batch production, and high-volume manufacturing

Manufacturing Process for Precision Parts

| Step | Process | Description |

|---|---|---|

| 1 | Material Selection | Choose suitable metal, plastic, or composite materials based on performance requirements. |

| 2 | Initial Shaping | Rough cutting or CNC milling to form the base shape of the part. |

| 3 | CNC Machining | Apply 3-axis, 4-axis, or 5-axis milling and CNC turning for tight tolerances and complex geometries. |

| 4 | Swiss Turning (Optional) | Manufacture thin-walled and intricate components with high precision. |

| 5 | Heat Treatment & Surface Finishing | Apply hardening, anodizing, plating, or coatings to enhance durability and wear resistance. |

| 6 | Inspection & Quality Control | Perform ISO-standard dimensional and quality checks for consistency. |

| 7 | Assembly & Final Testing | Assemble parts (if required) and simulate real-world applications. |

| 8 | Packaging & Delivery | Securely pack and ship worldwide with full traceability. |

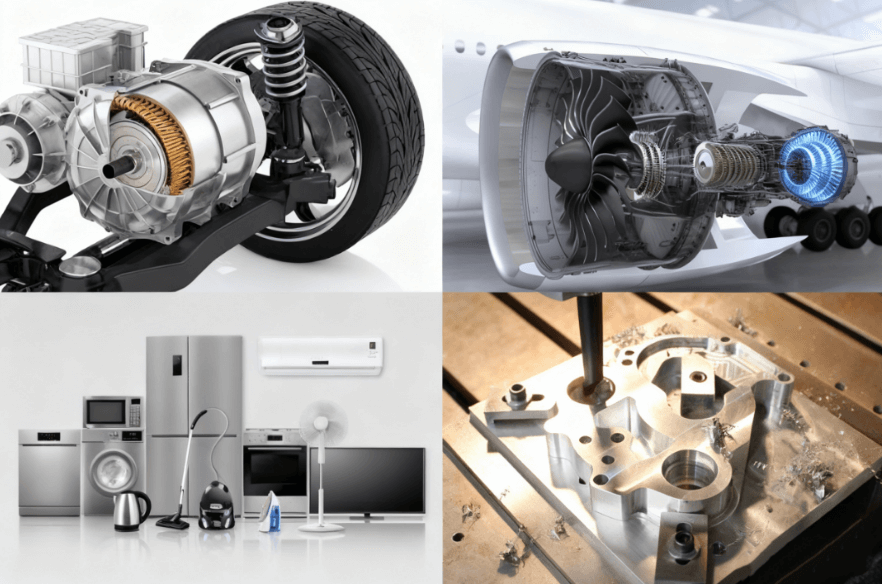

Application Areas

Aerospace: Engine and APU components, flight control equipment, thermal management parts, valves, sensors, and electrical connectors

Defense: Weapon components, guidance system housings, precision frames, and protective housings requiring tight tolerances

Automotive: Engine, transmission, and battery parts, radiators, lighting components, valves, and electronic connectors

Electronics & Industrial Manufacturing: PCB shields, sensor housings, microconnectors, and machine tool components

FAQs About Precision parts

Our precision machining reaches tolerances as tight as ±0.002 mm, ensuring consistent accuracy across batch production.

We handle steel alloys, aluminum, titanium, plastics, and composite materials depending on application requirements.

CNC milling and turning (3/4/5-axis), Swiss turning for thin-walled parts, heat treatment, anodizing, plating, and specialized surface coatings.

Every part undergoes ISO-standard inspections, dimensional checks, and quality control procedures to ensure reliability.

Yes, we handle prototypes, small-batch runs, and large-volume production with consistent precision and customization.

Need customization, please contact us

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN