When choosing a machining method for CNC precision parts, accuracy is one of the most critical decision factors. The difference between three-axis and five-axis machining directly affects dimensional tolerances, surface quality, production efficiency, and overall part consistency. In CNC precision parts machining, even minute deviations can lead to assembly problems, functional failures, or increased production costs. Here, we provide a direct, practical comparison of 3-axis and 5-axis machining for CNC precision parts, focusing on machining accuracy. We will explain to every user who needs CNC precision parts how these two methods affect setup accuracy, tool orientation, and tolerance control.

Precision Machining Technology for CNC Precision Parts

CNC machining accuracy refers to the ability to consistently produce parts that meet specified dimensions, tolerances, and geometric requirements. It includes not only linear dimensional accuracy but also positional accuracy, flatness, roundness, and surface finish. For a CNC precision part, accuracy directly affects assembly fit, functional reliability, and long-term performance. Many factors influence machining accuracy, including machine tool rigidity, spindle stability, tool quality, thermal control, and toolpath strategy. Furthermore, the number of setups and the amount of manual intervention also play a crucial role. The fewer repositioning operations required for CNC precision parts, the lower the risk of accumulated errors. Therefore, when accuracy is the primary consideration, the choice of machining strategy is as essential as machine tool performance.

3-Axis CNC Precision Part Machining

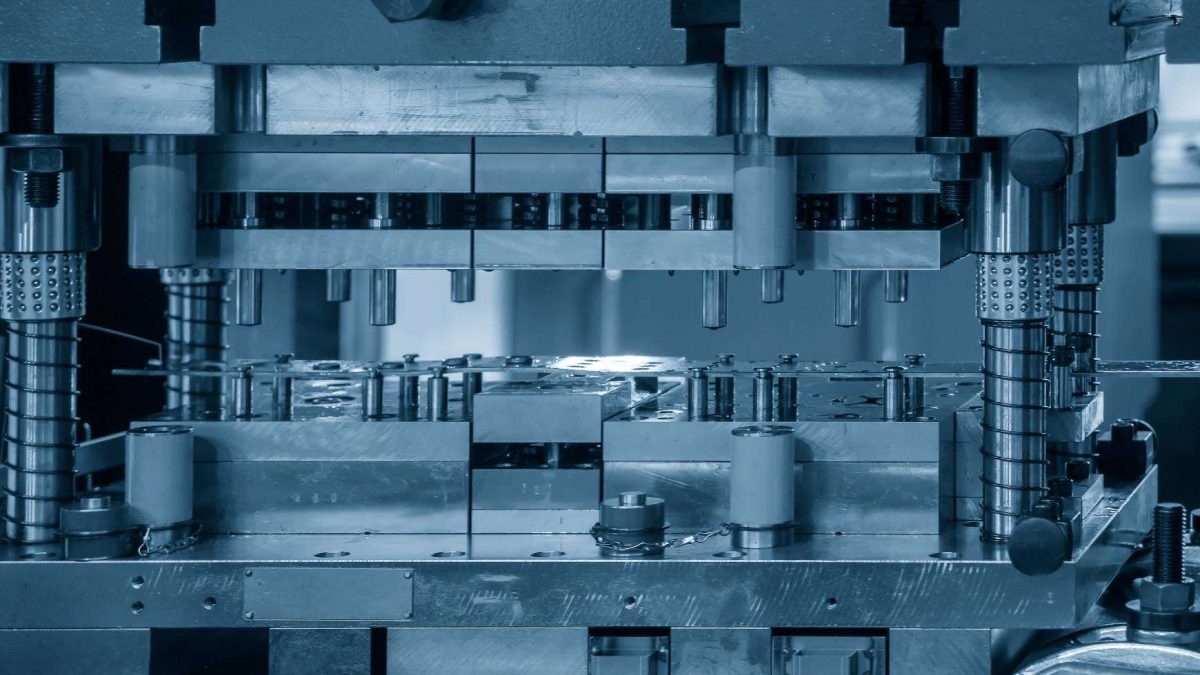

3-axis CNC precision part machining is performed along the X, Y, and Z linear axes. It is widely used due to its ease of operation, cost-effectiveness, and compatibility with various part designs. For simple cavities, grooves, and basic contours, three-axis machining delivers reliable, repeatable results.

However, limitations arise when machining complex CNC precision parts. Machining polyhedral features often requires multiple clamping operations, increasing the possibility of misalignment. Each reclamping introduces minor positioning deviations, which accumulate and affect overall accuracy. While skilled operators and precise fixtures can mitigate these risks, three-axis machining presents challenges when producing highly complex parts with strict tolerance requirements.

5-Axis CNC Precision Parts Machining

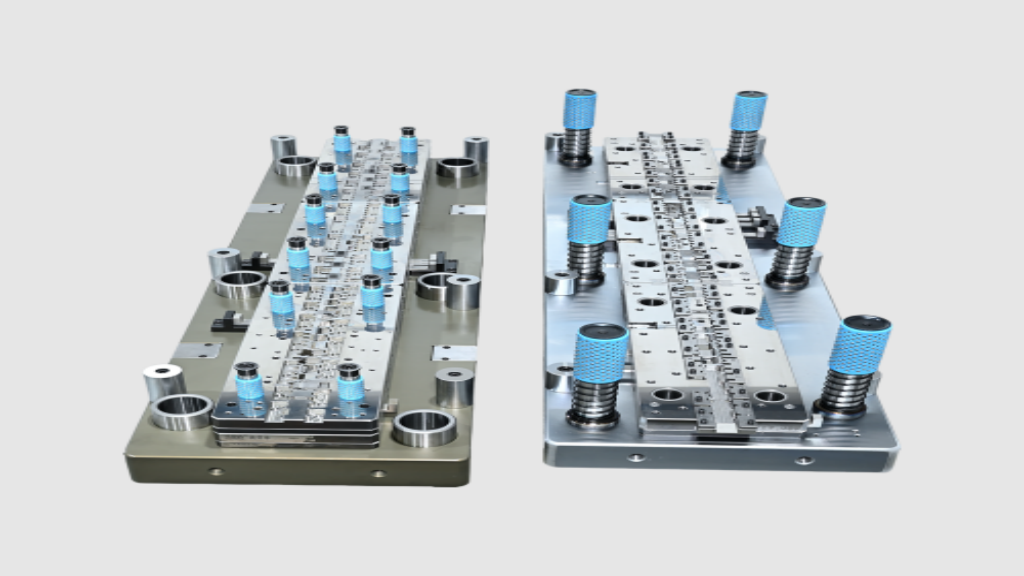

5-axis CNC precision parts machining adds two rotary axes to standard 3-axis linear machining, thus expanding machining capabilities. This allows the cutting tool to approach precision parts from almost any angle in a single setup. Therefore, complex geometries, chamfers, and freeform surfaces can be machined with extremely high precision.

From a precision perspective, 5-axis machining offers significant advantages. Continuous machining reduces repositioning errors, while optimized tool orientation minimizes tool deflection and vibration. These factors contribute to tighter tolerances, superior surface finishes, and higher dimensional consistency, making it particularly suitable for aerospace, medical, and high-end industrial precision parts.

Comparison of Machining Accuracy between 3-Axis and 5-Axis CNC Precision Parts

Setting the frequency is one of the most critical factors affecting the machining accuracy of precision parts. In 3-axis machining, complex parts often require multiple setups to machine different surfaces. Even with precision fixtures, each setup introduces potential alignment deviations.

In contrast, 5-axis CNC machining of precision parts typically completes most or all features in a single setup. This method significantly reduces accumulated errors and improves batch repeatability. For parts with strict geometric tolerances, fewer setups directly translate to higher precision and more consistent quality.

Tool Orientation and Surface Quality

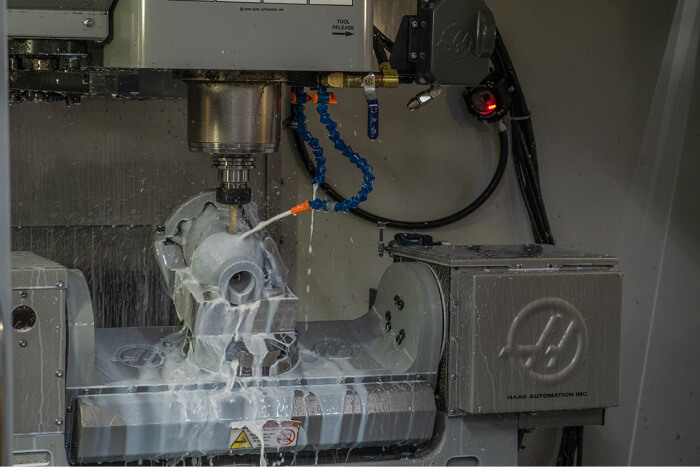

Tool orientation significantly impacts cutting stability and surface integrity. In 3-axis machining, a restricted tool angle can result in more extended tool overhangs, increasing the risk of chatter and deflection. These issues negatively affect surface finish and dimensional accuracy.

5-axis machining maintains optimal tool orientation throughout the cutting process. By keeping the tool perpendicular to the machined surface, cutting forces are evenly distributed. This results in smoother surfaces, reduced tool wear, and improved machining accuracy, especially when machining curved or irregularly shaped CNC precision parts.

Choosing the Appropriate Precision Machining Method

The choice between 3-axis and 5-axis machining depends on the part’s complexity, tolerance requirements, and end application. For simple parts, optimized 3-axis machining offers excellent cost-effectiveness. For highly complex parts requiring higher precision and surface quality, 5-axis machining is the better choice. At Chaoyang, we individually evaluate each precision part to ensure the machining method meets functional requirements and quality expectations. This approach enables us to consistently deliver precision parts that meet or even exceed industry standards.

Choosing a Precise and Reliable CNC Machining Solution

The precision of CNC-machined parts depends not only on the machine tool’s performance but also on how well the machining method matches the part’s complexity and tolerance requirements. For CNC precision parts with simple geometries and easily machinable features, 3-axis machining is a reliable, cost-effective solution that delivers consistent accuracy through simple clamping operations. In contrast, 5-axis machining provides higher precision for complex CNC precision parts by reducing the number of clamping operations, improving tool positioning, and maintaining tighter tolerances on complex surfaces.