When it comes to precision tooling, few debates are as common as the comparison between CNC machining and Wire EDM. Both are advanced subtractive manufacturing methods, yet they rely on entirely different principles. Understanding their differences is critical if you want to hit your project’s accuracy, speed, and budget goals.

Understanding the Two Processes

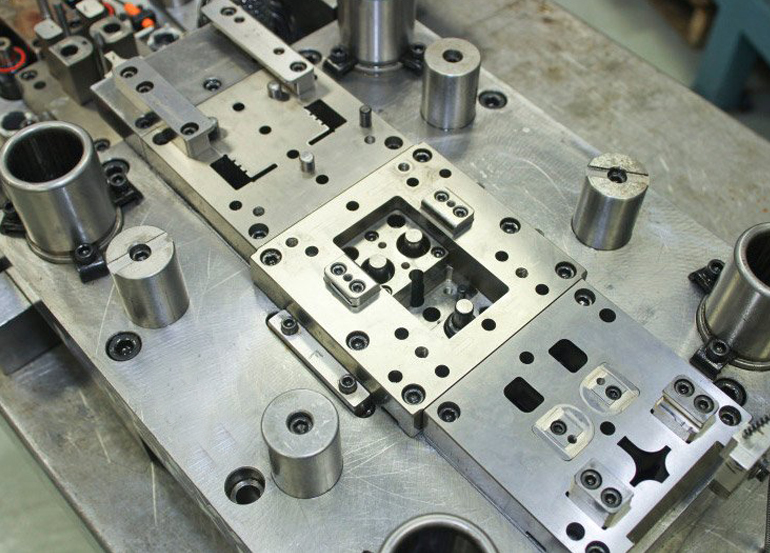

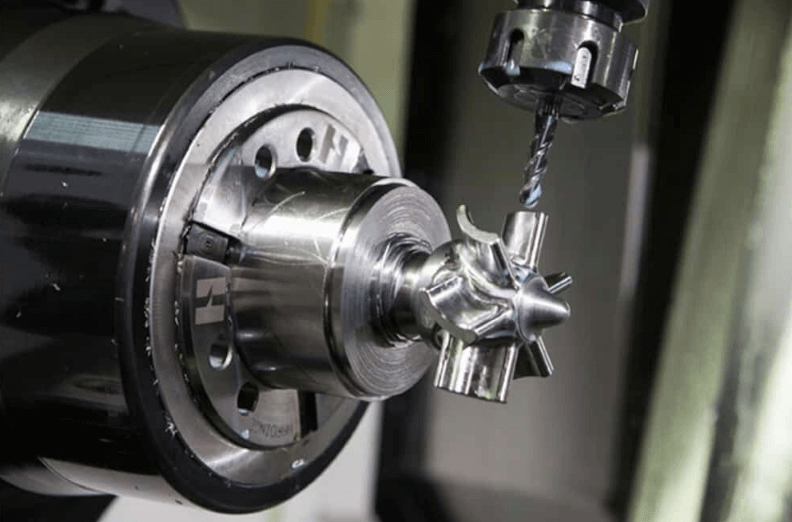

CNC Machining (Computer Numerical Control) utilizes rotating cutting tools to remove material from a solid block of material. The process follows pre-programmed paths created by CAD/CAM software. It’s highly flexible, handling everything from aluminum prototypes to hardened steel molds.

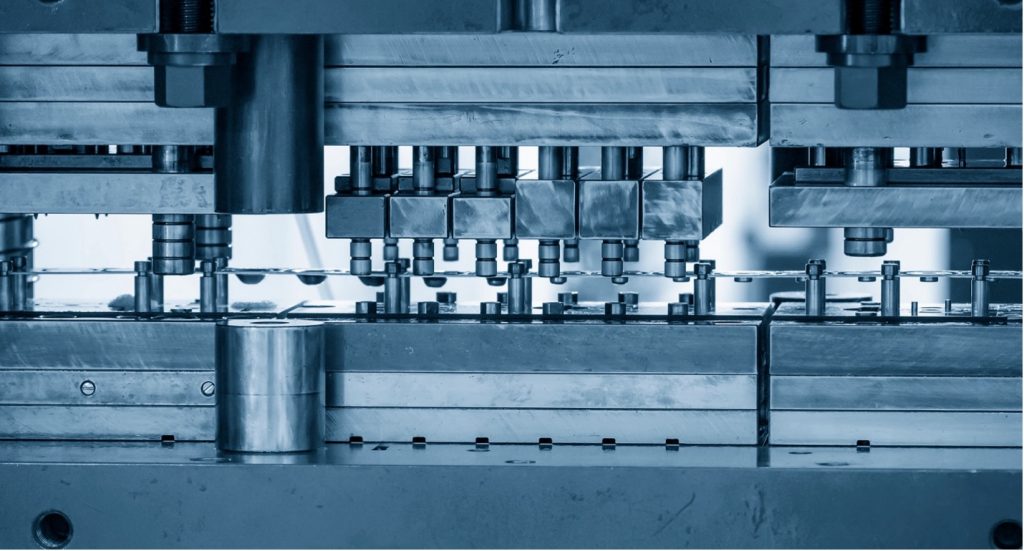

Wire EDM, also known as Electrical Discharge Machining, operates without physical contact. A thin wire, typically made of brass, generates controlled sparks that melt and vaporize metal. This erosion-based process can cut hardened materials or delicate features that would be damaged under traditional machining forces.

Accuracy and Surface Quality

If your project demands ultra-tight tolerances, Wire EDM takes the lead. It can routinely achieve accuracies of ±0.002 mm and perfectly sharp inside corners. That’s why it’s preferred for die inserts, fine blanking tools, and precision cavities.

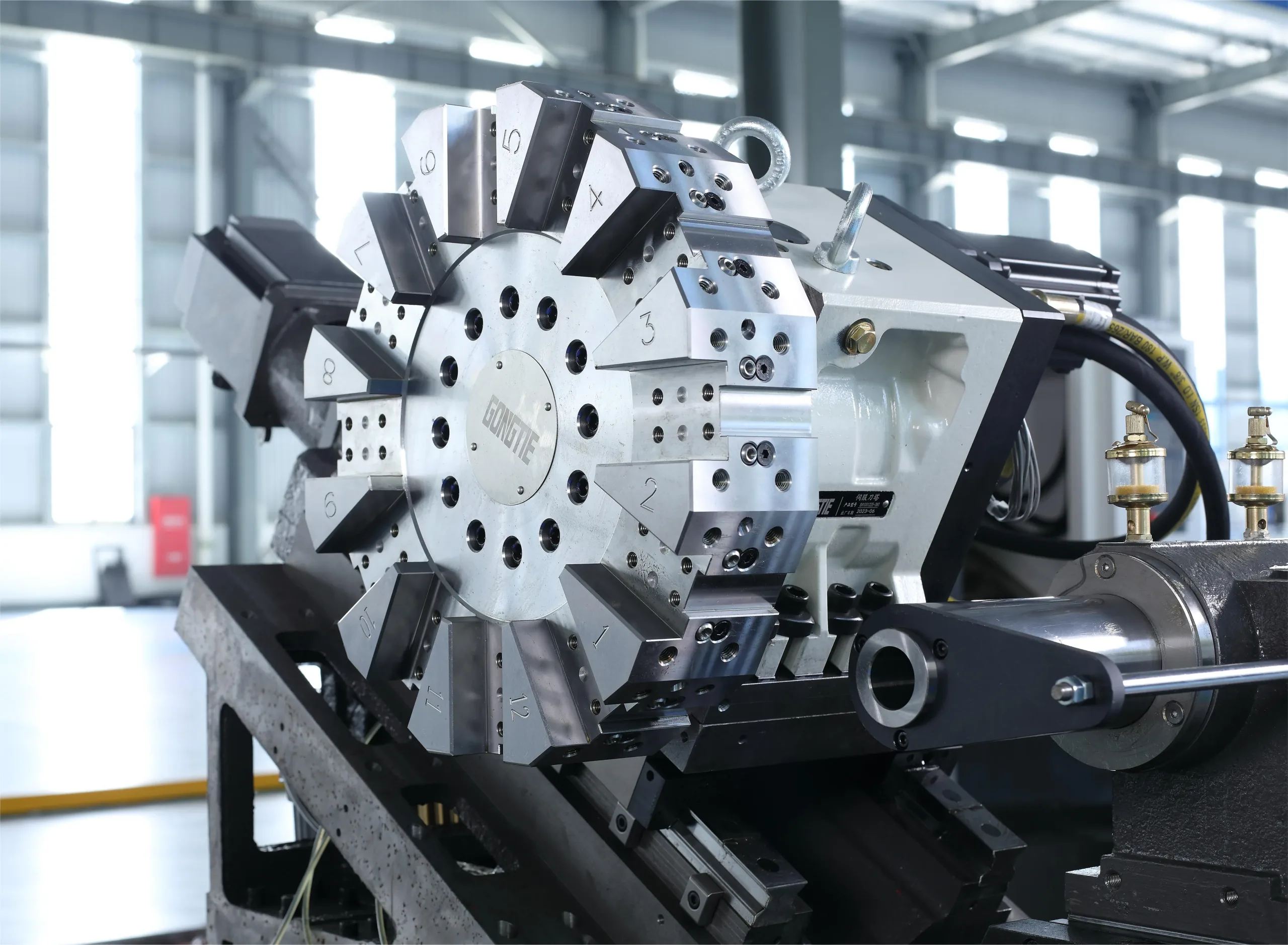

However, modern CNC Machining has evolved significantly. With 5-axis machines, thermal compensation systems, and micron-level tool calibration, it can now achieve ±0.005 mm tolerances while offering smoother surface finishes—especially after high-speed milling or polishing.

Cutting Speed and Efficiency

When time is money, CNC Machining dominates. High-speed spindles and automatic tool changers make it ideal for removing bulk materials. For example, machining a steel mold cavity typically takes 4–6 hours using CNC, compared to 10–12 hours using EDM.

That said, Wire EDM shines in unattended, long-cycle operations. Modern EDM systems can run overnight with automatic wire threading, requiring minimal operator supervision. While the erosion rate is slower, the reduced labor cost often balances the difference.

Tooling and Maintenance Costs

Every process has its own cost structure. CNC Machining involves expenses for cutting tools, fixtures, and coolant systems, as well as frequent tool wear—especially when cutting hardened steel above 50 HRC. Replacing carbide end mills can add up quickly in high-volume production.

Wire EDM utilizes brass wire, dielectric fluid, and filters while experiencing minimal mechanical wear. Over time, it becomes more economical for precision components that would otherwise damage cutting tools. For small-batch or complex tooling projects, EDM’s slower pace may still result in a lower total cost per part.

Material and Design Considerations

The choice also depends on material hardness and geometric complexity. CNC Machining excels at working with softer metals and parts that require deep cavities, threaded holes, or complex contours. It’s the go-to for aluminum molds, injection tooling bases, or general mechanical components.

In contrast, Wire EDM effortlessly handles hardened steels, tungsten carbide, and heat-treated alloys. It can produce internal corners with a radius of 0.1 mm and intricate lattice structures without distortion. If your tooling requires razor-sharp profiles or delicate ribs, EDM is unmatched in its precision and accuracy.

Industry Case Studies

Top-tier manufacturers often combine both. For instance, Mitsubishi Electric reported that using CNC for roughing and EDM for finishing reduced total machining time by 35% while improving accuracy by 40%.

In aerospace applications, titanium brackets and jet engine components are rough-milled on a CNC machine, followed by EDM cutting for final tolerance control. Similarly, automotive mold shops rough-shape cavities using CNC machines before finishing critical inserts or ejector pin holes with EDM to achieve precise accuracy.

Choosing the Right Method

There’s no one-size-fits-all solution. If your focus is speed, flexibility, and cost efficiency, CNC Machining is your ally. When accuracy, fine detail, and material hardness are most important, Wire EDM is the more intelligent choice. Many tooling engineers now design their workflows around both methods—using CNC for initial shaping, EDM for precision detailing, and grinding for finishing. This hybrid approach maximizes the strengths of each technology while minimizing its weaknesses.

For easier comparison, I have summarized these two technologies in a table, enabling you to select the one that best suits your project’s needs.

| Category | CNC Machining | Wire EDM (Electrical Discharge Machining) |

|---|---|---|

| Working Principle | Removes material using rotating cutting tools. | Uses electrical discharges to erode conductive material. |

| Material Requirements | Works with metals, plastics, and composites. | Works only with conductive materials such as steel, copper, and titanium. |

| Precision Level | Typically ±0.01 mm depending on machine quality. | Achieves precision of up to ±0.002 mm for micro-detail parts. |

| Surface Finish | Requires post-processing for fine finishes. | Produces mirror-like finishes without polishing. |

| Speed and Efficiency | Faster for larger parts and rough machining. | Slower but ideal for intricate or fine-detail components. |

| Tool Wear and Maintenance | Cutting tools wear out and require replacement. | No physical tool contact, resulting in minimal wear. |

| Part Geometry | Better for 3D shapes, cavities, and bulk removal. | Ideal for sharp corners, thin walls, and intricate contours. |

| Application in Tooling | Suited for molds, dies, and general machining. | Used for precision inserts, punch dies, and hardened tool steels. |

| Cost Efficiency | More cost-effective for large-scale production. | More expensive but offers higher precision for specialized parts. |

| Heat-Affected Zone | Generates cutting heat that may affect tolerances. | Produces minimal thermal distortion due to non-contact cutting. |

CNC Machining or Wire EDM

So, which is better for your tooling project—CNC Machining or Wire EDM? The truth is, both have their place. CNC delivers unmatched productivity and design flexibility, while EDM ensures perfection down to the micron. The most efficient shops don’t choose between them; they integrate both to achieve superior quality, lower costs, and faster turnaround