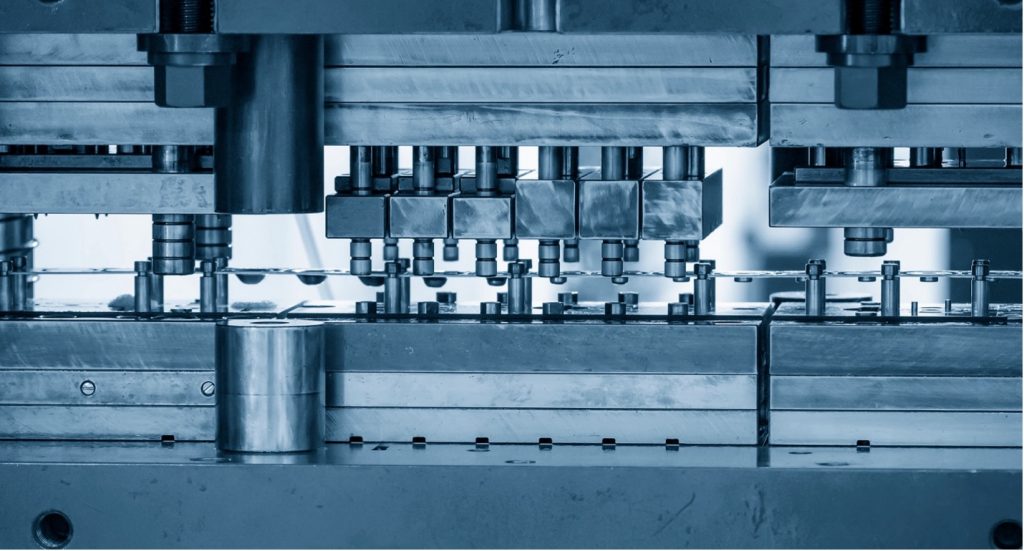

Progressive Stamping Dies has quickly become essential in the production of complex metal parts. Manufacturers across automotive, aerospace, electronics, and industrial sectors now rely on them for precise, high-volume metal parts production. These dies work by feeding metal sheets through a series of stamping stations. Each station performs a different task, such as cutting, bending, or forming. This continuous process reduces manual labor and eliminates unnecessary handling. As demand for intricate parts grows, Progressive Stamping Dies offers the ideal solution to maintain speed, precision, and cost control in highly competitive industries.

High Efficiency and Faster Production Cycles

One of the most significant advantages of Progressive Stamping Die is its ability to speed up production. These dies perform multiple operations within a single press cycle. This dramatically reduces the time needed for each part.

In many industries, meeting tight deadlines is critical. Progressive Stamping Dies allow manufacturers to produce large quantities of complex parts in short timeframes. Additionally, this method minimizes downtime between operations since all processes are consolidated. By reducing setup time and streamlining production, companies can meet high-volume demands without sacrificing part quality or consistency.

Enhanced Precision and Repeatability

Precision plays a vital role in metal parts manufacturing. Progressive Stamping Die offers exceptional accuracy throughout the production process. Each station in the die performs specific functions with exact measurements.

This repeatability ensures consistent results for every part produced, which is crucial for industries where tight tolerances are required. Over time, this consistent accuracy helps reduce scrap rates and material waste. By focusing on precision and repeatability, Progressive Stamping Dies helps manufacturers deliver reliable, high-quality products with minimal variation across production runs.

Cost Reduction Through Material Optimization

Progressive Stamping Die also enables significant cost savings through material optimization. These dies are designed to use metal sheets efficiently, minimizing excess waste during production. This directly reduces material costs.

Additionally, the high-speed nature of progressive Stamping lowers labor expenses by reducing manual intervention. Manufacturers also benefit from lower tool maintenance costs because progressive dies are built for durability. Combined, these factors make Progressive Stamping Dies a cost-effective solution for producing intricate metal components, particularly in industries with tight budget constraints.

Flexibility for Complex and Multi-Step Parts

Progressive Stamping Dies provide outstanding flexibility when creating complex parts with multiple features. They can handle various tasks such as punching, coining, embossing, and forming within a single die set.

This capability makes them ideal for products requiring several forming stages. Manufacturers can adjust or fine-tune die stations to accommodate design changes without retooling entire systems. This flexibility allows companies to respond quickly to market shifts and new product requirements. As a result, Progressive Stamping Dies serves as a highly adaptable solution for evolving production needs.

Consistency Across High-Volume Production Runs

Consistency is another significant benefit of Progressive Stamping Dies. Once the die is set up correctly, it produces identical parts throughout large production runs. This reduces quality control issues and improves customer satisfaction.

Furthermore, automated feeding systems enhance uniformity by precisely aligning each metal strip during processing. Combined with the inherent stability of progressive dies, this setup ensures every part meets strict specifications. Manufacturers can confidently rely on Progressive Stamping Dies to maintain consistent part quality over millions of cycles, reducing the risk of costly product recalls.

Simplified Workflow and Automation Integration

Progressive Stamping Dies simplifies manufacturing workflows by consolidating multiple steps into one automated process. This reduces the need for additional machinery and manual handling between operations.

Additionally, these dies integrate well with modern automation systems, including robotic arms and conveyor systems. This integration not only improves production speed but also minimizes human error. By adopting Progressive Stamping Dies, companies can create streamlined, highly efficient production lines capable of operating with minimal oversight while maintaining high output levels.

Why Stamping Dies Are the Ultimate Choice for Complex Metal Parts

Progressive Stamping dies are the first choice for manufacturers who are looking for complex metal parts because they are fast, accurate, and cost-effective. These Stamping dies are efficient, precise, and adaptable, allowing companies to meet the growing demand for complex components.