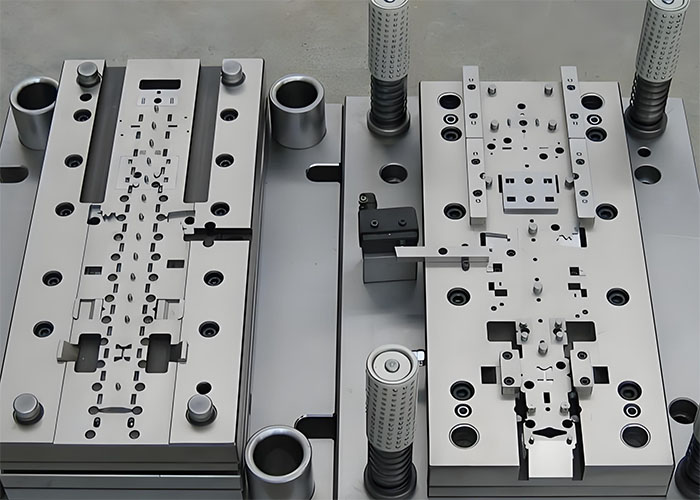

The precision of parts is critical in the automotive industry. Stamping dies are used to form metal parts that must meet tight tolerances, especially in high-volume production. Automakers can rely on high-precision stamping dies to ensure that each part meets engineering specifications. The consistency of these processes reduces assembly errors and improves overall product quality while minimizing production delays.

Enhancing Structural Integrity Through Precise Stamping

Vehicle safety depends heavily on the strength of its structural components. The stamping die must deliver parts with precise dimensional control to ensure a seamless fit. High-accuracy stamping dies enable manufacturers to maintain the integrity of crumple zones and frame components without deviation, thereby supporting critical safety features.

Additionally, uniform thickness across each stamped part contributes to improved crash performance and more even load distribution. Precise dies ensure that reinforcements, brackets, and pillars perform under pressure. This reliability becomes especially vital in meeting evolving safety regulations across global markets and satisfying insurance rating criteria.

Efficiency Gains in Mass Production

Automotive production lines operate at immense speed, and downtime is costly. High-accuracy stamping dies help maintain uptime by providing longer tool life and reducing maintenance requirements. When dies consistently produce exact parts, operators spend less time correcting misalignments or adjusting downstream processes.

Furthermore, precision tooling minimises scrap material, reducing waste and improving sustainability. Manufacturers also gain efficiencies in quality control as fewer parts fall outside tolerance bands. These gains compound over long production cycles, making precision dies a sound long-term investment for high-output operations.

Supporting Lightweighting and Material Innovation

The shift toward lightweight vehicles demands more than just new materials. It requires dies capable of processing aluminium, high-strength steel, and composites without compromise. High-accuracy stamping dies are specifically designed for this challenge, providing the rigidity and fine-tuning required for non-traditional metals and complex shapes.

In parallel, new materials introduce more variation in spring back and forming behaviour. Precision dies help mitigate these issues through advanced modelling and tighter manufacturing tolerances. This capability enables automakers to pursue innovation without sacrificing manufacturability or repeatability in the process.

Compatibility with Automation and Robotics

Automation continues to reshape automotive assembly, from robotic welding to automated stamping cells. High-accuracy dies fit perfectly into this evolving ecosystem. Their precision ensures that robotic arms can predictably handle parts without adjustment or cycle-time delays.

Also, consistency in part dimensions improves throughput in automated stations and reduces false rejections. Sensors and vision systems rely on uniformity, and precision dies support that reliability. As automation becomes increasingly advanced and data-driven, the demand for compatible tooling also grows in parallel.

Cost Savings Through Tool Longevity

Tooling costs are a significant factor in automotive production budgets. High-accuracy stamping dies, though more expensive upfront, offer better durability and long-term performance. They maintain tolerances longer, reducing the need for frequent refurbishment or replacement over the product lifecycle.

This extended tool life also reduces line interruptions and unscheduled maintenance. Less frequent die changes mean more continuous operation and fewer calibration runs. Over time, these savings outweigh initial costs, especially for high-volume platforms that run for years with minimal changeovers.

Tailored Solutions for OEM-Specific Needs

No two automotive manufacturers are the same. Each has unique design priorities, part geometries, and volume expectations. High-accuracy stamping dies can be customized to meet these exact needs with engineered solutions. From CAD design to final hardening, die shops offer tailored workflows for OEMs worldwide.

Moreover, precision tooling supports tighter integration between design and manufacturing teams. As vehicle platforms become increasingly complex, this alignment helps reduce development cycles and time to launch. The result is a competitive advantage in a fast-moving and innovation-driven market.

The Impact of Stamping Dies on Car Manufacturing

As the automotive industry accelerates toward electrification, autonomous driving technology, and greener practices, the role of precision stamping dies remains significant. From achieving lightweight body structures to meeting stringent crash safety standards to ensuring seamless integration with robotic assembly lines, precision stamping dies are essential.