Metal stamping dies are essential tools in the manufacturing process. They shape, cut, and form sheet metal into precision components. Choosing the right die depends on part design, production volume, material type, and required tolerances. Using an inappropriate die can lead to defects, material waste, and production delays. To avoid mistakes in die selection, read this article, which will explain the main types of metal stamping dies, their functions, and typical applications.

Blanking Dies

Blanking dies cut flat shapes from sheet metal. The cut piece, known as a blank, becomes the workpiece for subsequent operations. Blanking is widely used in the automotive, electronics, and appliance industries. These dies provide consistent dimensions, reducing material waste. In high-volume production, they improve speed and cost efficiency. Modern blanking dies often incorporate precision features, including die guides and ejectors, to prevent sticking and enhance accuracy. Selecting the right punch and die clearance ensures clean cuts and longer die life.

Piercing Dies

Piercing dies create holes or openings in sheet metal by removing material from it. They are used for mounting holes, slots, and ventilation patterns. Piercing can be combined with blanking in progressive tools to increase efficiency. Proper design prevents burrs, ensuring components fit correctly in assemblies. Piercing dies may include pilots, knockouts, and stripper plates for consistent operation. They are critical in industries where precision holes determine the final assembly performance, such as electronics or automotive brackets.

Forming Dies

Forming dies bend or stretch metal into desired shapes without removing material. They are used for flanges, channels, and curved profiles. Aerospace, automotive, and appliance industries rely on forming dies to produce structural components. Consistent bends reduce stress concentration and prevent cracking. Forming dies may use multiple stations or adjustable stops to maintain uniformity. Lubrication and proper press tonnage are crucial in avoiding springback and achieving a superior surface finish. Selecting the right material thickness and die geometry ensures repeatable results.

Drawing Dies

Drawing dies pull sheet metal into a cavity to create deep, hollow parts. They are used for cans, sinks, automotive panels, and complex enclosures. Controlling the flow of metal prevents tearing and wrinkling. Drawing dies can operate in single-stage or multi-stage processes, depending on the depth and complexity of the part being produced. Lubrication, punch-die clearance, and speed are critical factors. Multi-stage drawing dies gradually form parts, reducing stress and extending die life. Proper maintenance, including polishing and inspection, ensures consistent output and prevents defects from occurring.

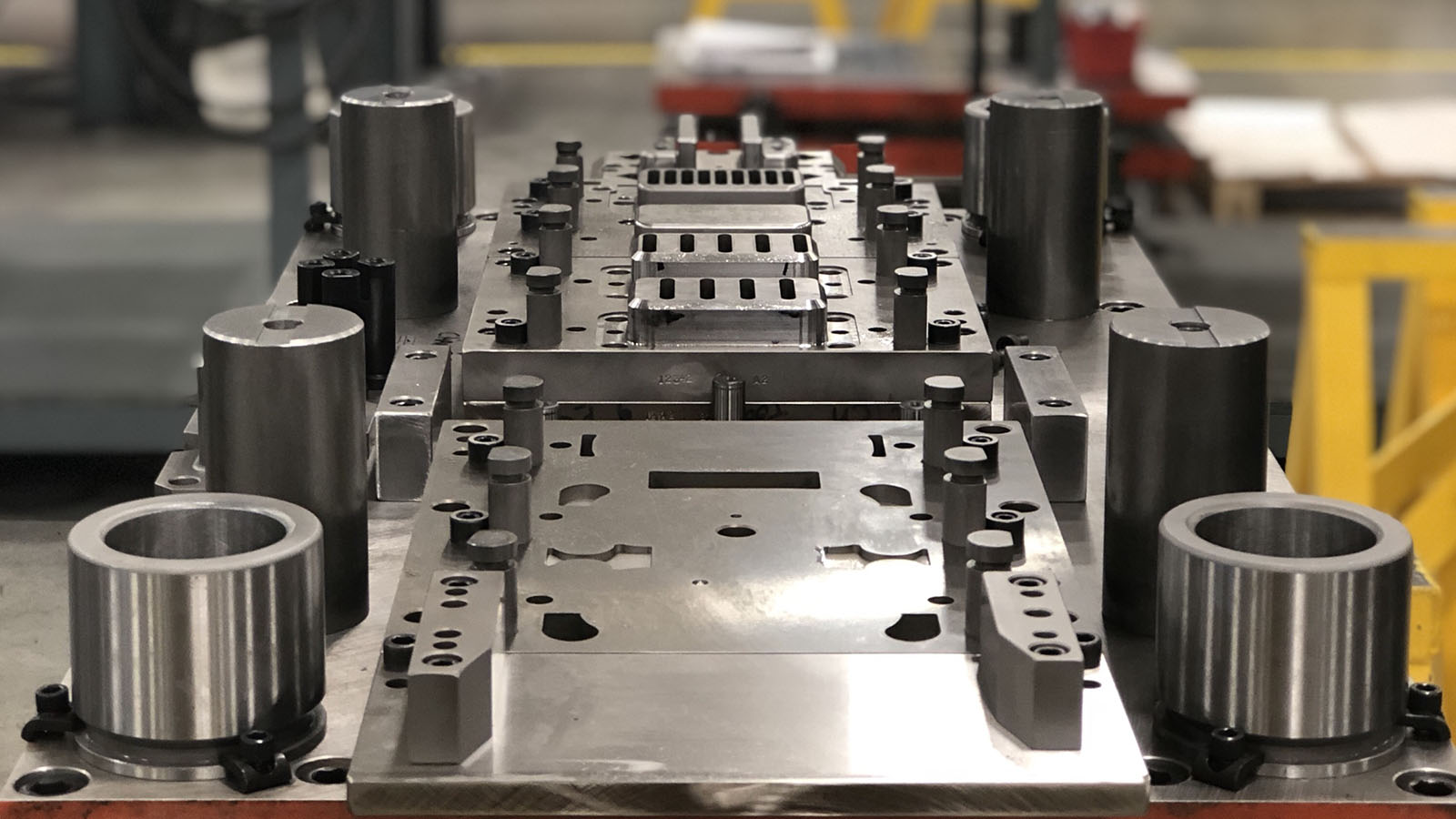

Progressive Dies

Progressive dies combine multiple operations into a single die set. Each station performs a step, such as blanking, piercing, and forming. The strip advances with every press stroke, producing finished parts at the end. Progressive dies reduce handling, increase speed, and are ideal for small to medium components. They allow tight tolerances and consistent quality in high-volume production. Modern progressive dies incorporate guides, feeders, and sensors to enhance automation and accuracy. Automotive connectors, brackets, and electronic components widely use them.

Compound Dies

Compound dies perform two or more operations in a single stroke, typically blanking and piercing. Unlike progressive dies, all actions occur in a single station. Flat parts requiring precise alignment between holes and outer shapes suit them well. Compound dies reduce the number of press strokes, improve efficiency, and maintain tight tolerances. They require precise setup, robust materials, and careful maintenance. Typical applications include washers, gaskets, and simple mounting brackets where repeatability is critical.

Transfer Dies

Transfer dies move individual blanks between stations with a mechanical transfer system. Each station performs a different operation, such as forming, drawing, or bending. They handle larger or more complex parts that progressive dies cannot accommodate. Transfer dies offer flexibility in complex designs and enable multiple operations without requiring manual handling. These dies are essential in heavy-gauge stamping and automotive body panels. Automation integration reduces cycle times, improves safety, and ensures part consistency across production batches.

Conclusion on Metal Stamping Dies

A Metal stamping die encompasses a range of types, including blanking, piercing, forming, drawing, progressive, compound, and transfer dies. Each type serves a specific role in shaping sheet metal and improving production efficiency. Selecting the right die depends on the part’s geometry, material, production volume, and the required tolerances. Understanding these types helps manufacturers optimise processes, reduce costs, and maintain high-quality output. Proper design, testing, and maintenance ensure long-term performance and reliability from metal stamping dies, supporting both small and large-scale production.