TOOLING COMPONENTS

- Home

- Application

- TOOLING COMPONENTS

Tooling Components

Typical Data Sheet (General Specification)

| Component Type | Material Options | Tolerance | Hardness (HRC) |

|---|---|---|---|

| Guide Post & Bushing | SKD11 / SKH-9 / SUJ2 | ±0.005 mm | 58–62 HRC |

| Punch & Die Insert | Tungsten Steel / ASP23 | ±0.003 mm | 60–66 HRC |

| Ejector Pin | HSS / NAK80 | ±0.01 mm | 50–56 HRC |

| Stripper Plate | Tool Steel / Mild Steel | ±0.05 mm | Customized |

| Custom Parts | As per drawing | As requested | As required |

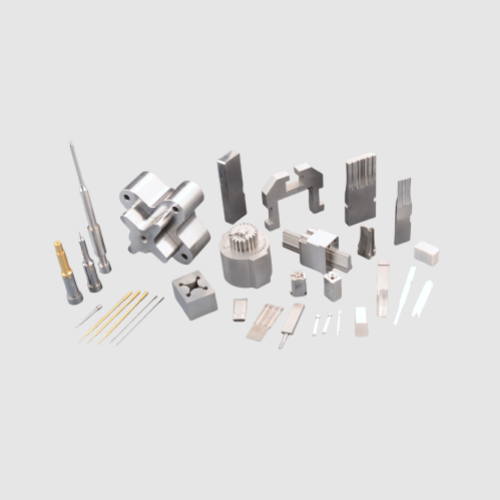

Product Description

We manufacture and supply a full range of Tooling Components tailored for precision stamping dies, plastic injection molds, and automation tooling systems. Designed to meet the demanding requirements of high-volume production, our components deliver exceptional durability, accuracy, and consistency.

Our product line includes guide posts, guide bushings, punches, dies, ejector pins, stripper plates, alignment blocks, lifters, and custom-made tooling parts. Whether you need standard items or custom-engineered solutions, we ensure perfect fitment and performance for every application.

With advanced CNC grinding, EDM machining, and strict quality control, we provide tooling components that support high-speed, high-precision manufacturing in automotive, electronics, medical, and consumer goods industries.

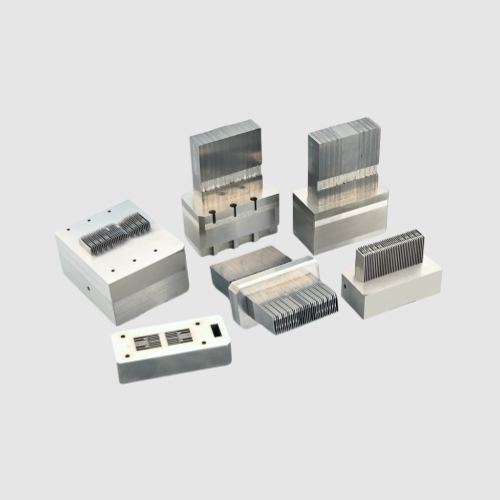

Key Features and Advantages

Precision Machined: Dimensional tolerance as tight as ±0.002 mm

High Hardness Materials: SKD11, SKH-51, tungsten steel, and carbide options

Surface Treatments: Nitriding, TiN/TiCN/TiAlN coating, DLC coating

Standard & Custom Sizes: Compatible with MISUMI, DME, HASCO, and custom specs

Long Tool Life: Suitable for millions of cycles in harsh production environments

Wide Application: Metal dies, injection molds, progressive stamping, fine blanking

FAQs about Tooling Components

Yes. We offer full OEM/ODM services and accept 2D/3D files in all major formats (STEP, IGES, DWG, etc.). Our engineers can also assist in optimizing designs for production.

We serve a wide range of industries including automotive, consumer electronics, aerospace, telecom, and home appliances.

We use advanced precision machining equipment and 100% inspection with CMM, optical projectors, and hardness testers to ensure every part meets your spec.

Absolutely. We ship to clients across North America, Europe, and Southeast Asia. Our components meet international standards and integrate easily into global systems.

Standard parts ship in 3–5 days. Custom tooling components usually require 7–15 working days depending on complexity.

Need customization, please contact us

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN