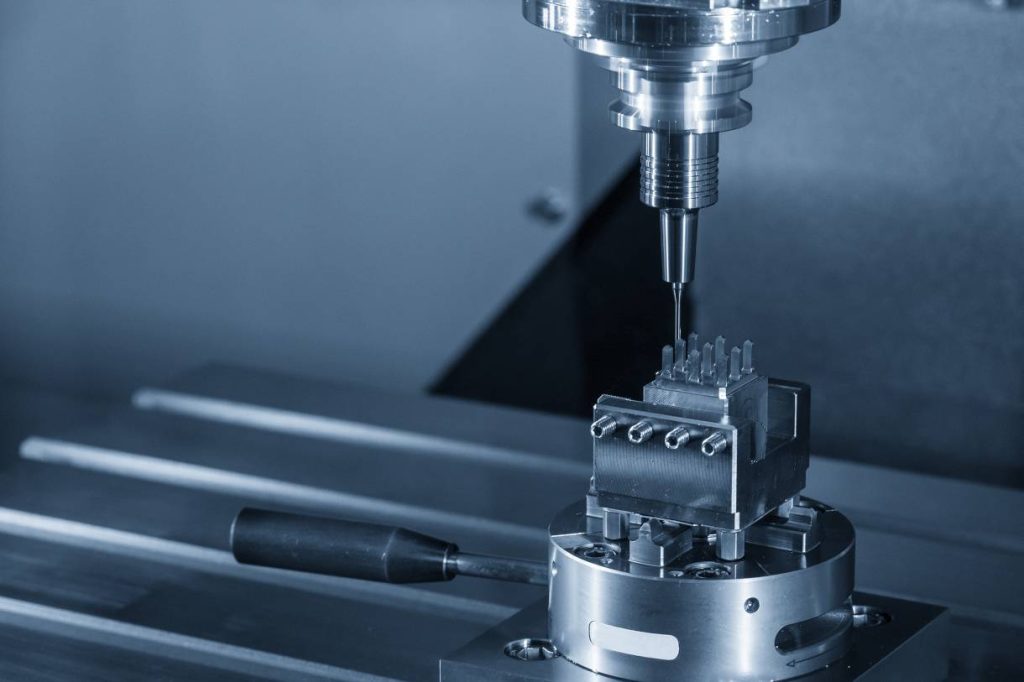

Precision-machined parts form the backbone of modern robotics and automation systems. These components guarantee the tight tolerances required for advanced functionality. Without these parts, many robotic systems would struggle to achieve accurate and consistent movements. Moreover, the use of Precision Machining Parts ensures the smooth operation of complex automation equipment. Their exact dimensions and flawless finishes significantly reduce operational friction and mechanical stress. As industries evolve toward automation, these components play an increasingly critical role in enhancing performance and ensuring long-term reliability.

Enhancing Motion Control and Precision

Precision-machined parts have a significant impact on motion control within robotics. These components provide exact fits and precise alignment, consistently reducing errors in repetitive tasks. For robotic arms and automation modules, such control is indispensable for optimal functioning.

Additionally, these parts enable high-speed operations without sacrificing accuracy. The close tolerances minimize mechanical play, resulting in stable, predictable motion patterns. As a result, many advanced automation systems rely on Precision Machining Parts to optimize performance, reduce energy losses, and improve productivity.

Improving Durability in Harsh Environments

Robotics and automation systems often operate in challenging conditions. The Precision Machining Part withstands exposure to extreme temperatures, chemicals, and high-pressure environments reliably. This resistance ensures consistent performance throughout the product lifecycle, even in rugged applications.

Furthermore, these parts contribute to the long-term durability of the entire system. Their robust construction and precision manufacturing significantly minimize wear and tear. Companies can reduce maintenance frequency, lower downtime risks, and effectively extend the overall service life of their equipment.

Customization for Specialized Applications

Another significant advantage of Precision Machining Parts lies in their customization potential. Engineers can design components to meet specific automation requirements, including unique geometries and material combinations for demanding environments.

This level of customization enables businesses to optimize system performance precisely according to their operational needs. Whether improving speed, load capacity, thermal resistance, or durability, Precision Machining Parts offers tailored solutions for specialized robotics applications with unmatched accuracy.

Enhancing System Integration

Precision-machined parts facilitate seamless integration across various automation systems. Their standardized designs and precise specifications facilitate easy assembly, seamless alignment, and modular upgrades.

Additionally, these parts ensure seamless connectivity between mechanical components and digital control systems. This integration enhances coordination, enabling smoother transitions between automated tasks. Ultimately, businesses can scale their robotics systems efficiently by leveraging Precision Machining Parts in large-scale automation projects.

Reducing Operational Costs

Cost efficiency remains a top priority for most industries today. Precision Machining Parts contribute to cost savings by reducing machine failures, minimizing material waste, and improving operational efficiency.

Their long-lasting durability significantly reduces the need for frequent replacements. Furthermore, their precise construction decreases energy consumption, enhances output consistency, and improves overall operational effectiveness. Over time, companies benefit from lower maintenance expenses and higher return on investment with minimal disruptions.

Meeting Rigorous Industry Standards

Precision Machining Parts adheres to strict industry standards to ensure quality, safety, and compliance across industries. Manufacturers often produce these components in ISO-certified facilities, guaranteeing consistent performance under rigorous conditions.

These parts also comply with specialized industry certifications, such as those required in aerospace, medical, or defense robotics sectors. By meeting these standards, Precision Machining Parts ensures high reliability, minimizes risks and enhances compatibility for critical automation applications globally.

Maximizing Robotics Performance with Precision Machining Parts

Precision-machined parts are an essential component of robotics and automation systems. Their accuracy, exceptional durability, and superior customization capabilities can meet the world’s changing industrial needs. By integrating these components, manufacturers can achieve superior performance, greater operational efficiency, and lower long-term costs. As automation technology rapidly advances, the role of precision machined parts will grow, consolidating their position as a key element of the next generation of technology in the robotics and automation industry.