PRECISION JIGS

- Home

- Application

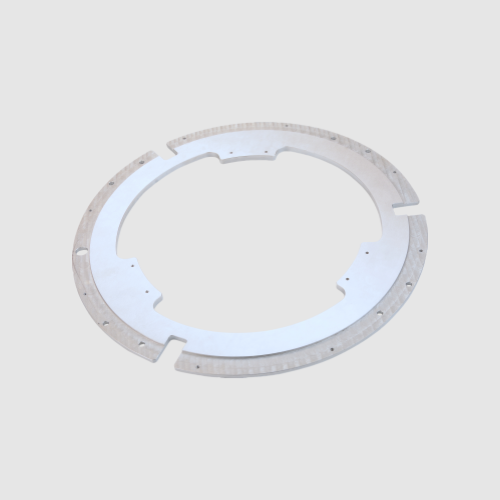

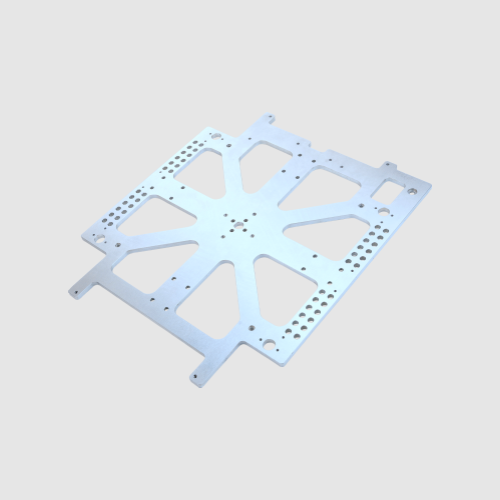

- PRECISION JIGS

PRECISION JIGS

Typical Data Sheet (General Specification)

| Jig Type | Use Case | Material Options | Tolerance |

|---|---|---|---|

| Drilling Jigs | Precision hole alignment on metal parts | Tool Steel / Aluminum | ±0.01 mm |

| Inspection Fixtures | Part measurement & dimensional checks | Granite / Steel | ±0.005 mm |

| Welding Jigs | Multi-axis holding for welding setups | Cast Iron / Steel | ±0.02 mm |

| Assembly Jigs | Component alignment & fastening | Aluminum / Plastic | ±0.01 mm |

| Custom Jig Systems | Full integration with automation lines | Mixed materials | As specified |

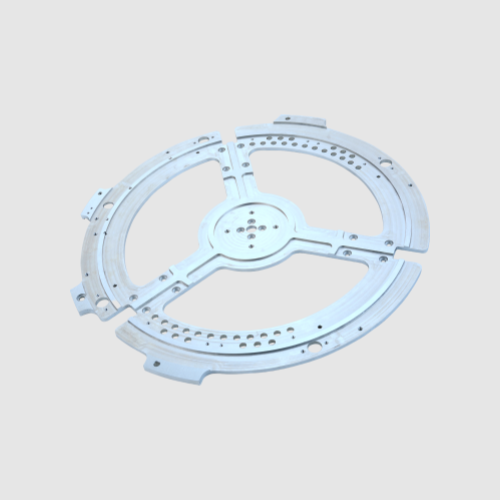

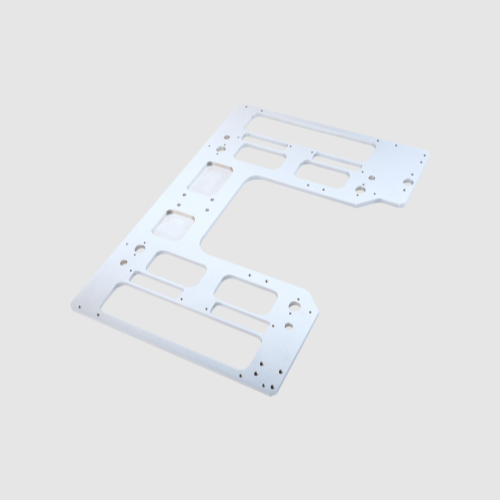

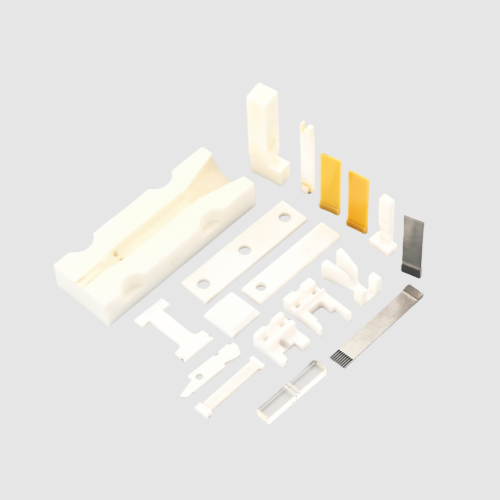

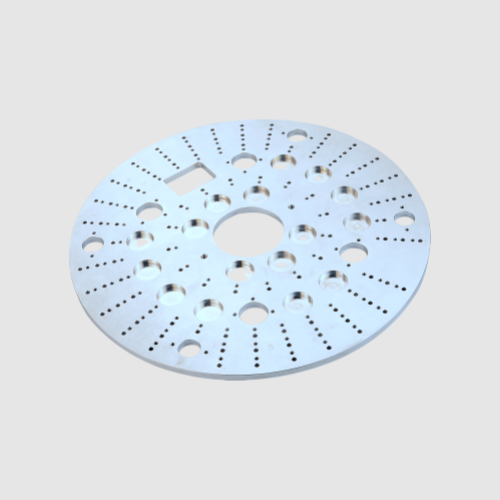

Product Description

Our Precision Jigs are engineered to deliver superior accuracy, repeatability, and efficiency across a wide range of manufacturing and assembly applications. Whether used in CNC machining, drilling, inspection, or welding processes, our jigs help reduce setup time, improve alignment precision, and ensure consistent product quality.

Built with hardened tool steel, aluminum alloys, or custom composite materials, our jigs are tailored to meet industry-specific demands—ranging from electronics and automotive to aerospace and medical device manufacturing. From standard locator jigs to complex multi-functional fixtures, we support both OEM and ODM production with full design-to-delivery services.

Every jig is custom-built or manufactured to ISO tolerances, ensuring optimal fitment and stable performance under high-cycle usage.

Key Features and Advantages

High Dimensional Precision: Tolerances up to ±0.005 mm for critical surfaces

Modular Designs: Easily adaptable to different workpieces and equipment

Long-Term Stability: Built from wear-resistant alloys and engineered for repeat use

Full Compatibility: Integrates seamlessly with CNC machines, CMMs, and welding benches

Reduced Setup Time: Speeds up part clamping, positioning, and alignment

Custom Engineering: We support one-off prototypes and large-scale batch production

FAQs About Precision Jigs

Yes, we provide full design, prototyping, and production services based on your technical drawings or functional requirements. We support OEM/ODM for global clients.

Our jigs serve sectors like automotive, aerospace, consumer electronics, precision machining, medical device production, and more.

For simple jigs, the lead time is 7–10 working days. For complex or multi-functional systems, it may take 15–25 working days depending on scope.

Absolutely. We design jigs to fit various sizes and shapes, including custom clamping and locating features for complex geometries.

We conduct 100% inspection with CMMs and laser measuring tools. Every jig is verified under simulated working conditions before delivery.

Need customization, please contact us

Pellentesque scelerisque auctor scelerisque.

© 2025 Technical Support By LEZHAN