CNC Precision Parts vs Traditional Precision Parts: Precision Comparison

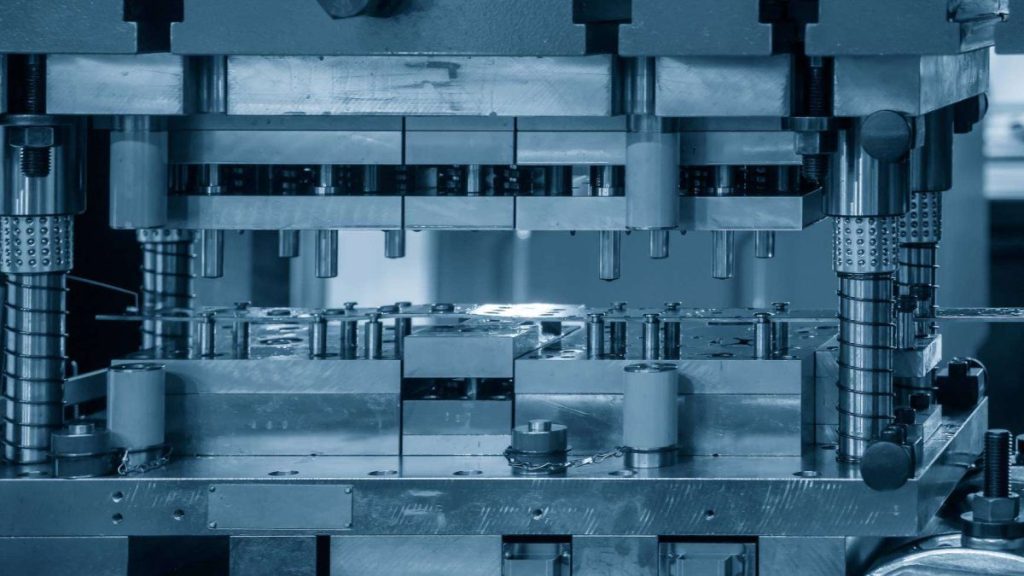

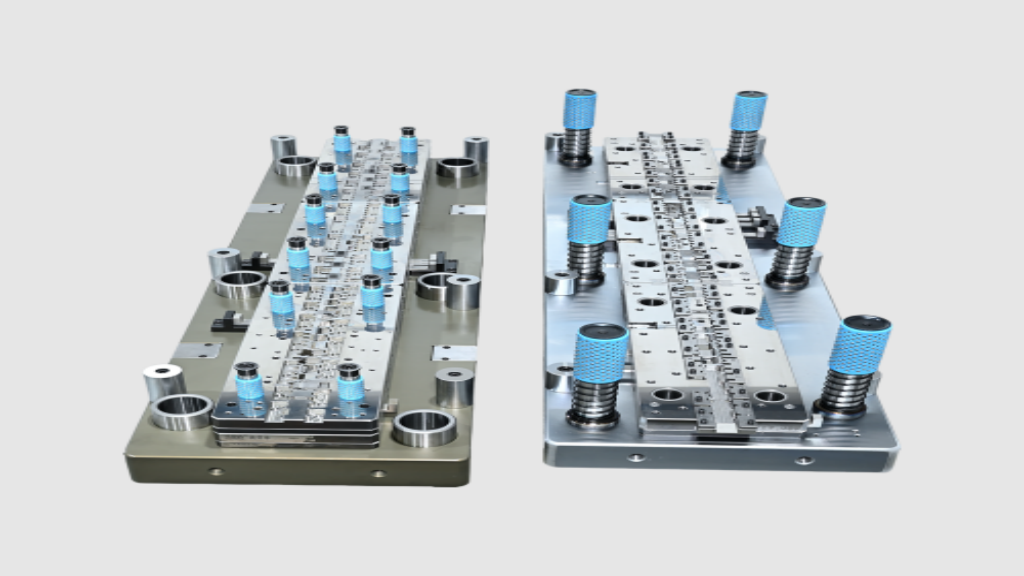

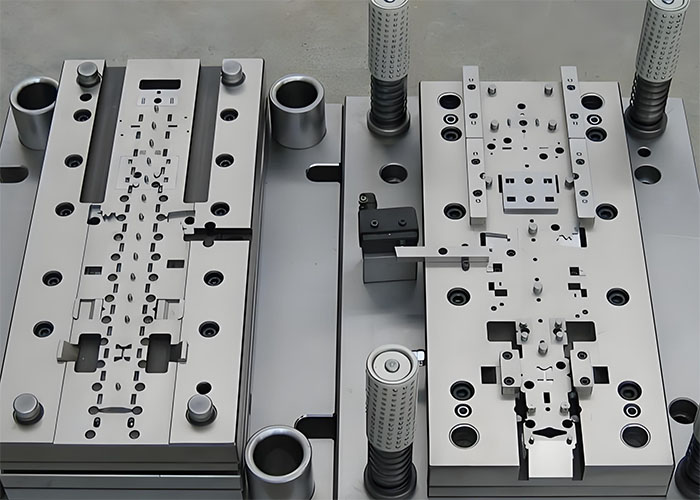

Our engineers are frequently asked whether CNC machining produces parts with superior performance compared to conventional methods. The real question is: “Which combination of processes, materials, inspection, and planning can meet your product’s required tolerances, surface finish, and repeatability at an acceptable cost and delivery time?” We will compare CNC precision parts and conventional precision parts from the perspective of all key attributes in production: dimensional accuracy, geometric control, surface quality, repeatability, throughput, material selection, process risk, and cost. Precision of CNC Precision Parts vs. Conventional Precision Parts Precision is not just about tight tolerances; it’s also about repeatability, geometric stability, and long-term functional performance. In parts manufacturing, CNC precision parts represent a data-driven, digitally controlled approach to achieving precision. Unlike conventional machining methods that heavily rely on operator experience, CNC systems operate through programmed toolpaths, closed-loop servo control, and automatic compensation systems. Today’s CNC machining centers integrate CAD/CAM programming, thermal compensation, high-resolution encoders, and real-time feedback loops. These technologies work together to reduce axis misalignment, spindle runout, and geometric error accumulation. Therefore, the dimensional tolerances of the CNC precision part is typically ±0.01 mm or less, depending on the application requirements. In contrast, traditional precision parts are usually produced using manual lathes, milling machines, coordinate grinders, and skilled manual finishing techniques. While these methods can produce high-precision individual parts, they rely more on process skill than on digital repeatability. Therefore, although traditional machining still has value in specific situations, CNC-based production methods offer greater consistency in medium to high-volume production. Dimensional Accuracy and Geometric Control of CNC Precision Parts Dimensional accuracy can be measured, but geometric accuracy determines functional success. CNC precision parts benefit from multi-axis machining capabilities, significantly reducing repositioning and reclamping errors. For example, five-axis CNC machining can complete the machining of complex geometries in a single setup, minimizing accumulated tolerances. Furthermore, CNC machine tools integrate online probes and automatic tool compensation correction functions. These features ensure consistency across different production batches and reduce reliance on manual adjustments. CNC machine tools can maintain production efficiency while controlling positional accuracy, flatness, perpendicularity, and concentricity within extremely high tolerances. Therefore, when comparing CNC precision parts with traditional precision parts, the key difference lies not only in achievable tolerances but also in the repeatable geometric control of hundreds or thousands of parts. Surface Finish and Functional Fit Surface quality directly affects sealing performance, wear resistance, and mechanical life. The CNC precision part achieves consistent surface finishes through optimized toolpaths, high-speed spindles, coated tools, and vibration control systems. Feed rate regulation and constant chip load programming further enhance surface integrity. For applications requiring tight-sealed interfaces, bearing journals, or sliding fits, CNC machining provides predictable Ra values and uniform material removal patterns. Furthermore, advanced CAM software reduces toolpath marks and waviness height, improving surface smoothness without requiring excessive secondary finishing. Traditional methods, such as hand polishing or grinding, can achieve ultra-fine surface finishes under specific conditions. However, these methods are labor-intensive and difficult to scale up. Comparison of Operating and Economic Costs of CNC Precision Parts vs. Conventional Precision Parts Material selection typically determines the complexity of machining. CNC precision parts are suitable for a wide range of materials, including aluminum alloys, stainless steel, tool steel, copper alloys, titanium, and nickel-based alloys. Through programmable feed rates, adaptive cutting strategies, and coolant optimization, CNC can effectively control work hardening and heat buildup in difficult-to-machine materials. Furthermore, CNC platforms can be seamlessly integrated with electrical discharge machining (EDM) and precision grinding processes to handle internal cavities, deep ribs, and micro-features. Conventional machining methods can also process similar materials, but efficiency and repeatability may be affected when machining high-strength or heat-resistant alloys. Operator fatigue and manual adjustments further increase the variability in machining difficult-to-machine materials. Therefore, CNC precision parts offer significant technological advantages for industries with high material complexity and stringent tolerance requirements, such as aerospace, medical devices, automotive, and energy systems. Production Efficiency, Scalability, and Cost Structure Cost analysis must consider the economic benefits throughout the entire lifecycle, not just the machining time per piece. While CNC machining requires significant capital investment, it offers exceptional cost-effectiveness in medium- to high-volume production. This advantage lies in reduced manual labor, automated tool changes, shorter machining cycles, and minimized scrap rates. Software-based program modifications allow for rapid iteration without redesigning physical fixtures. This flexibility significantly enhances scalability. Traditional precision machining methods appear more cost-effective for single prototypes or very small batch production, especially when setup time is much longer than programming time. When to Choose CNC Precision Parts vs. Traditional Precision Parts The choice between CNC and traditional machining methods depends on application requirements. CNC precision parts should be chosen when: Tight tolerances must be maintained during mass production. Complex geometries require multi-axis machining. Materials include titanium, Inconel alloys, or hardened tool steel. Process traceability and digital quality records are mandatory. Large-scale production is a strategic priority. Traditional precision methods should be considered when: Creating a model with the simplest geometry and the simplest prototype. Performing specialized manual finishing operations. For emergency repairs or minor modifications. In many practical applications, a hybrid approach is the best choice. CNC machining efficiently generates the basic geometry, while selective conventional finishing ensures a superior surface finish when needed.